A high tap density lithium manganese iron phosphate positive electrode material and its preparation method and application

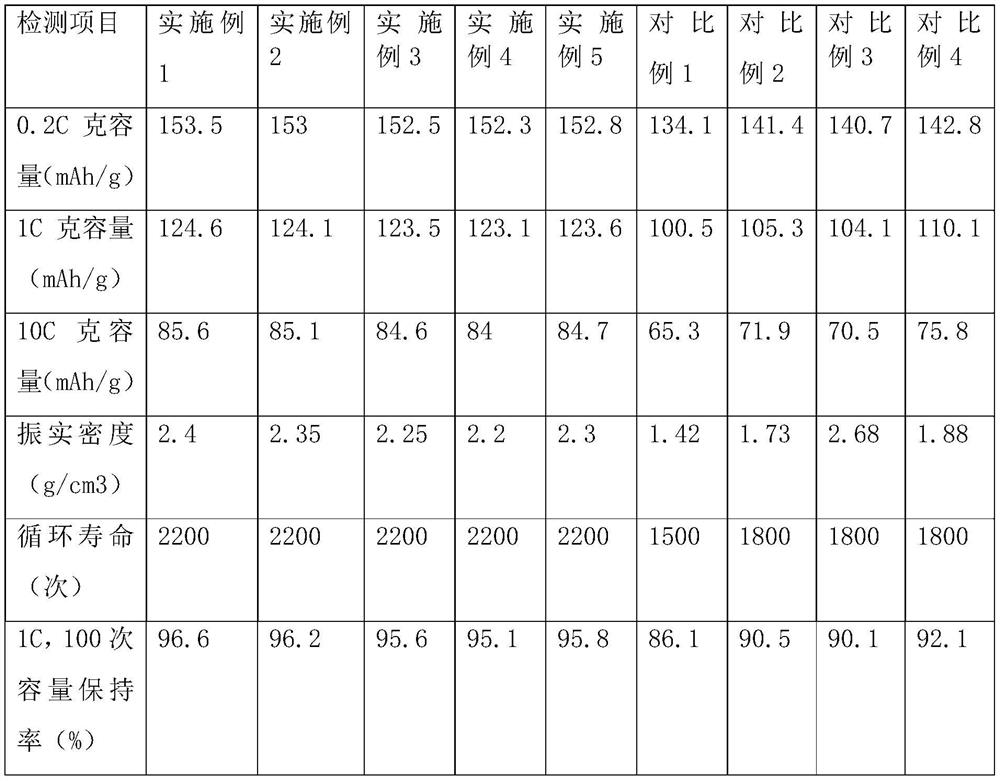

A technology of lithium iron manganese phosphate and cathode material, applied in chemical instruments and methods, battery electrodes, phosphorus compounds, etc., can solve the problems of low platform voltage, no batch protection circuits and chargers, application limitations, etc. The solid density, phase structure and chemical composition are uniform, and the cost of raw materials is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

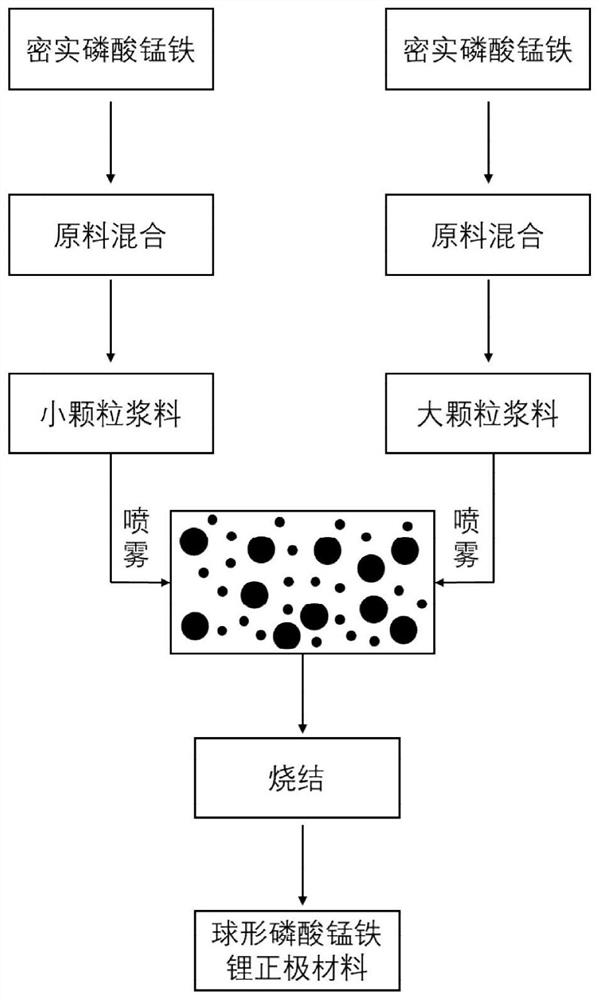

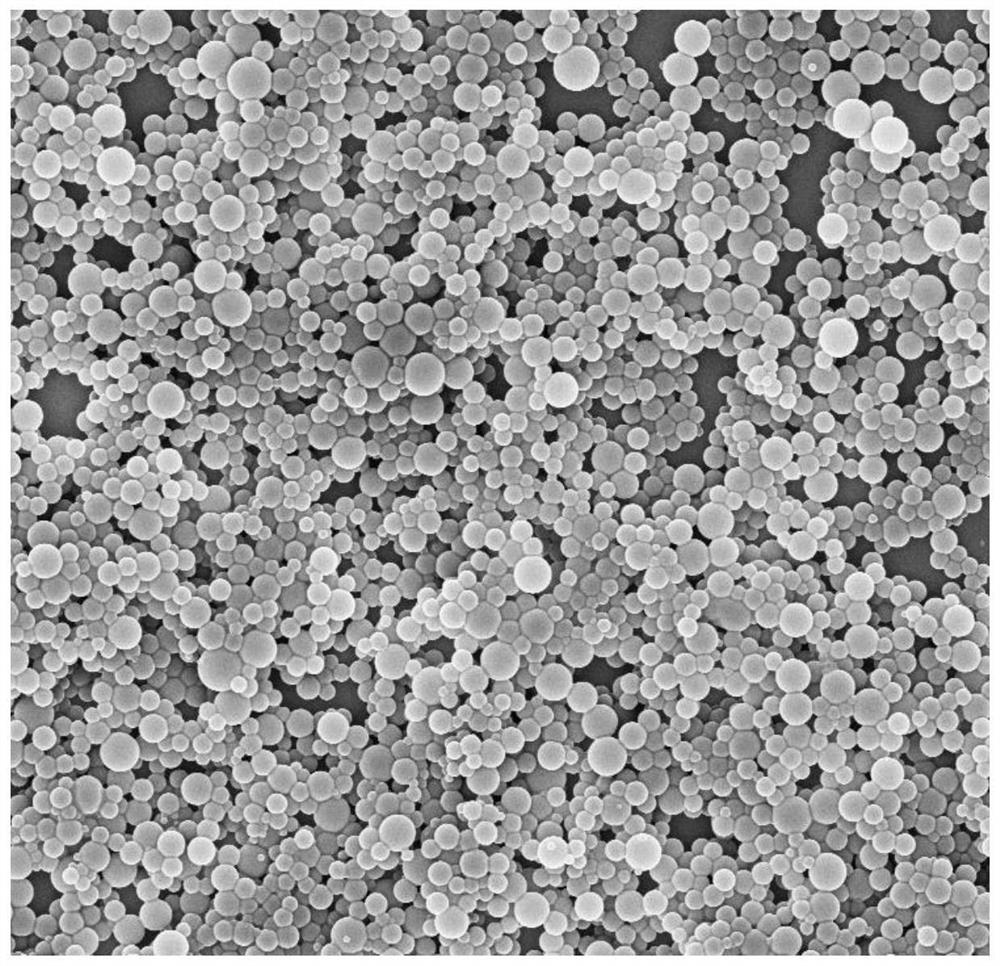

[0037] A high-tap density lithium manganese iron phosphate positive electrode material is formed by mixing small particles of lithium manganese iron phosphate with a particle size of 0.5um and large particles of lithium manganese iron phosphate with a particle size of 4um in a mass ratio of 7:3.

[0038] A method for preparing a high tap density lithium manganese iron phosphate positive electrode material, specifically comprising the steps of:

[0039] Step (1) preparation of dense ferromanganese phosphate:

[0040](1) Slowly add respectively a concentration of 10wt% ferric chloride solution, a concentration of 10wt% manganous chloride solution, a concentration of 15wt% ammonium dihydrogen phosphate solution, stearic acid and citric acid in a mass ratio of 1:4 The concentration of the composition is a mixed solution of 5mg / Ml, a concentration of 15wt% ammonia solution in a three-necked flask, wherein the molar ratio of iron salt, manganese salt, phosphorus source, mixed soluti...

Embodiment 2

[0051] A high-tap density lithium manganese iron phosphate positive electrode material is made of small particles of lithium manganese iron phosphate with a particle size of 0.3um and large particles of lithium manganese iron phosphate with a particle size of 5um in a mass ratio of 1:9.

[0052] A method for preparing a high tap density lithium manganese iron phosphate positive electrode material, specifically comprising the steps of:

[0053] Step (1) preparation of dense ferromanganese phosphate:

[0054] (1) Slowly add respectively a concentration of 5wt% ferric sulfate solution, a concentration of 8wt% manganese sulfate solution, a concentration of 10wt% diammonium hydrogen phosphate solution, dodecylbenzenesulfonic acid and citric acid in a mass ratio of 1:3 The concentration of the composition is a mixed solution of 8mg / mL, and a sodium hydroxide solution with a concentration of 12wt% in a three-necked flask, wherein the molar ratio of iron salt, manganese salt, phosphor...

Embodiment 3

[0065] A high-tap density lithium manganese iron phosphate positive electrode material is made of small particles of lithium manganese iron phosphate with a particle size of 0.8um and large particles of lithium manganese iron phosphate with a particle size of 3um in a mass ratio of 3:7.

[0066] A method for preparing a high tap density lithium manganese iron phosphate positive electrode material, specifically comprising the steps of:

[0067] Step (1) preparation of dense ferromanganese phosphate:

[0068] (1) Slowly add respectively a concentration of 8wt% ferric sulfate solution, a concentration of 9wt% manganese sulfate solution, a concentration of 12wt% diammonium hydrogen phosphate solution, dodecylbenzenesulfonic acid and citric acid in a mass ratio of 1:3 The concentration of the composition is a mixed solution of 7mg / mL, a sodium hydroxide solution with a concentration of 18wt% in a three-necked flask, wherein the molar ratio of iron salt, manganese salt, phosphorus s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com