Method for regulation of surface morphology based on change of polypyrrole polymerization time

A technology of surface morphology and polymerization reaction, applied in the field of preparation of polymer films, can solve the problems of limited application prospects, complicated operation and high cost, and achieve the effect of avoiding complex preparation process and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

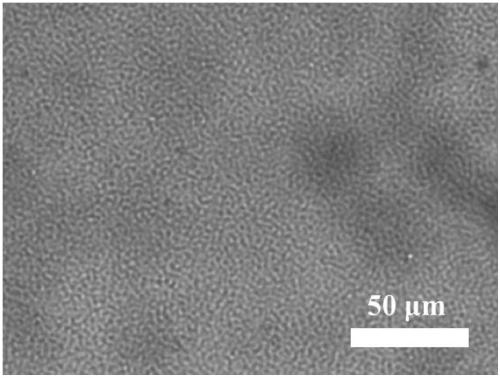

[0019] Embodiment 1: the method for regulating its surface morphology based on changing the polypyrrole polymerization reaction time, comprises the following steps:

[0020] Step 1: Mix the PDMS prepolymer and crosslinking agent according to the mass ratio of 10:1, pour it into a centrifuge tube, and stir with a glass rod to form a uniform mixture;

[0021] Step 2: vacuum degas the mixture of PDMS prepolymer and cross-linking agent for 1 hour, then pour it into a square petri dish, and make it evenly distributed in the petri dish;

[0022] Step 3: The mixture of prepolymer and crosslinking agent poured into the petri dish is vacuum degassed for 30 minutes, then put into an oven, and heated and cured at 70°C for 4 hours;

[0023] Step 4: Dissolve the pyrrole monomer in hydrochloric acid according to the mass volume ratio of 6.5 mg / ml, and ultrasonically mix to obtain solution A; according to the mass volume ratio of 30 mg / ml, dissolve ferric chloride in hydrochloric acid, and u...

Embodiment 2

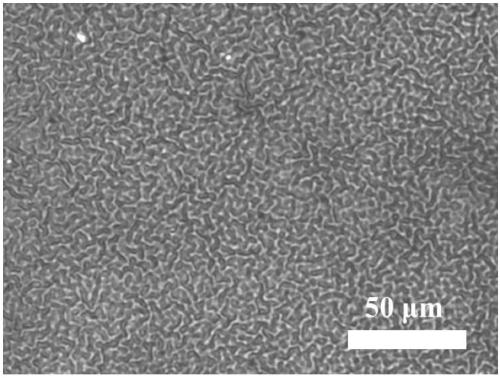

[0026] Example 2: A method for controlling the surface morphology of polypyrrole based on changing the polymerization reaction time. In Example 2, except that Step 4 and Step 5 are different from those in Example 1, other steps are the same. Step 4, change the mass volume ratio of pyrrole monomer to hydrochloric acid in solution A from 6.5mg / ml to 7.0mg / ml, change the mass volume ratio of ferric chloride in solution B to hydrochloric acid from 30mg / ml to 35mg / ml ml; in step five, adjust the polymerization reaction time to 5h. The optical microscope picture of the polypyrrole film that embodiment 2 finally obtains is as figure 2 shown.

Embodiment 3

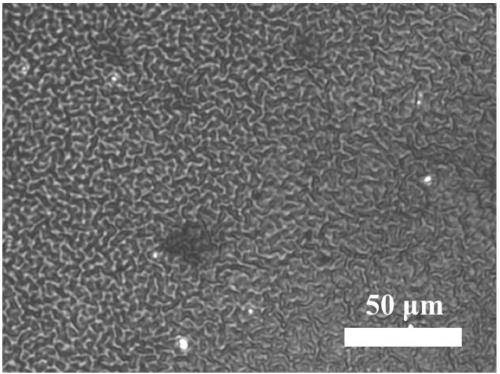

[0027] Example 3: A method for controlling the surface morphology of polypyrrole based on changing the polymerization reaction time. In Example 3, except that Step 5 is different from that in Example 1, other steps are the same. In step five, the polymerization reaction time is adjusted for 9 hours, and the optical microscope picture of the finally obtained polypyrrole film is as follows image 3 shown.

[0028] In summary, the present invention deposits a PPy film on a PDMS substrate, and uses the difference in modulus between the PDMS substrate and the PPy film to induce a surface pattern. By changing the PPy polymerization reaction time, and then changing the modulus of the PPy film, PPy films with different surface patterns were finally prepared. The longer the reaction time, the larger the period of the obtained polypyrrole film pattern. The method of the invention overcomes the previous shortcomings of complicated preparation process and poor process controllability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com