Split type rotatable multi-ring mycorrhizal compartment culture and treatment device

A treatment device and a split-type technology, which is applied in the field of arbuscular mycorrhizal fungi, can solve the problems of the interaction of environmental factors, the influence of the research on the mechanism of root system and extraroot mycelia, and the difficulty of regular sampling in separate chamber culture devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

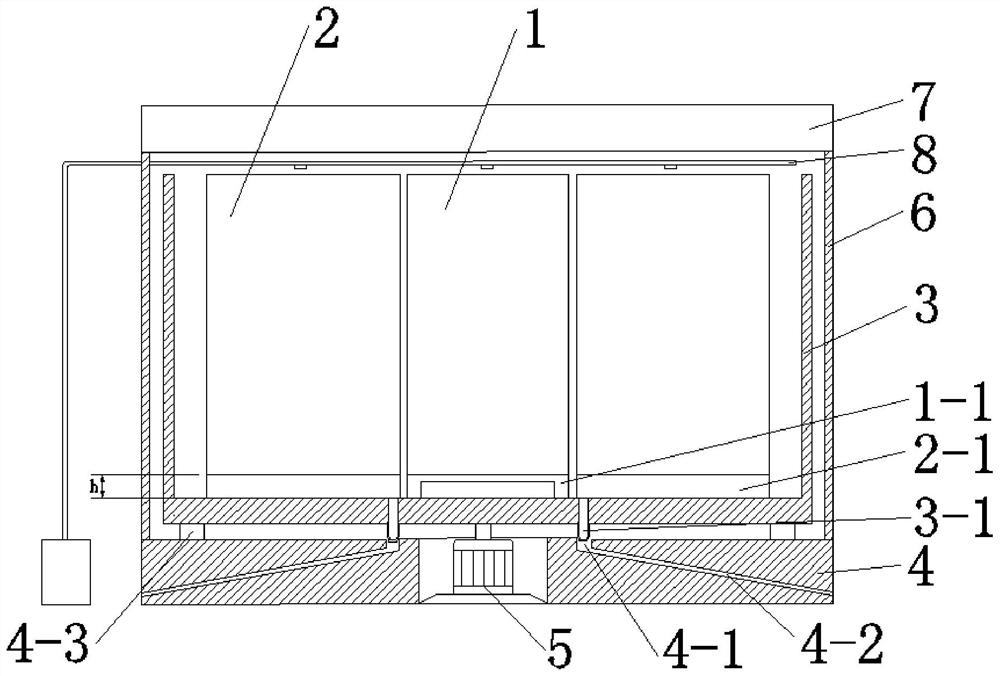

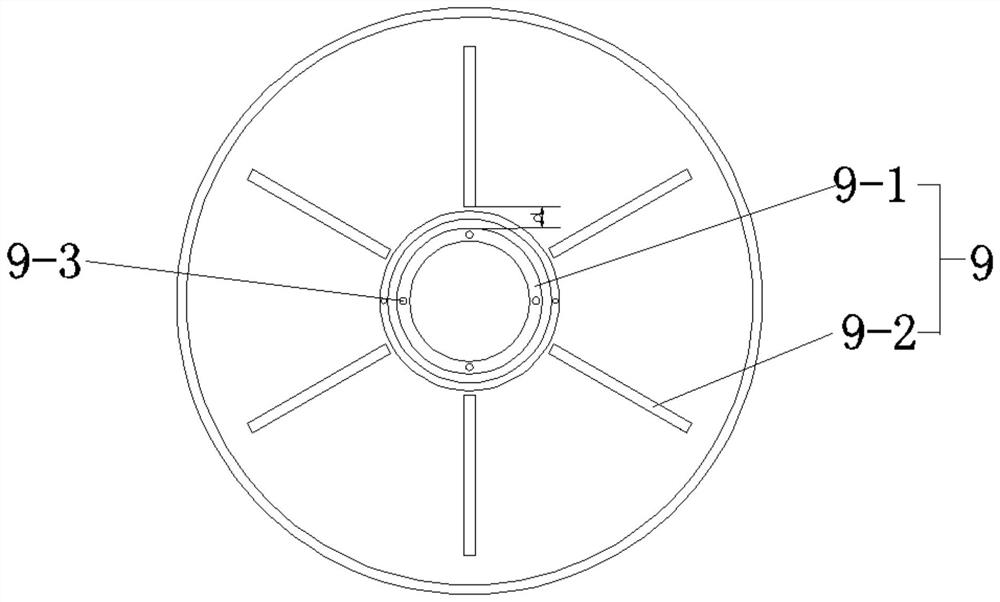

[0023] Specific Embodiment 1: The split-type rotatable multi-ring type mycorrhizal chamber culture and treatment device in this embodiment includes a plant growth chamber 1, a mycelium development chamber 2, an experimental control cylinder 3 and a base 4, and a motor is provided at the center of the base 4. room, the motor 5 is placed in the motor room, the rotating shaft of the motor 5 is perpendicular to the upper surface of the base 4, and an annular drain groove 4-1 is opened on the upper surface of the base 4, and the drain groove 4-1 is connected with the liquid outlet channel 4 -2 is connected, and a plurality of support rollers 4-3 are evenly arranged on the circumference of the upper surface of the base 4, the cylinder bottom surface of the experimental control cylinder 3 is in contact with the support rollers 4-3, and the experimental control cylinder 3 is driven by the motor 5 to rotate;

[0024] The plant growth chamber 1 is cylindrical, and the wall of the plant g...

specific Embodiment approach 2

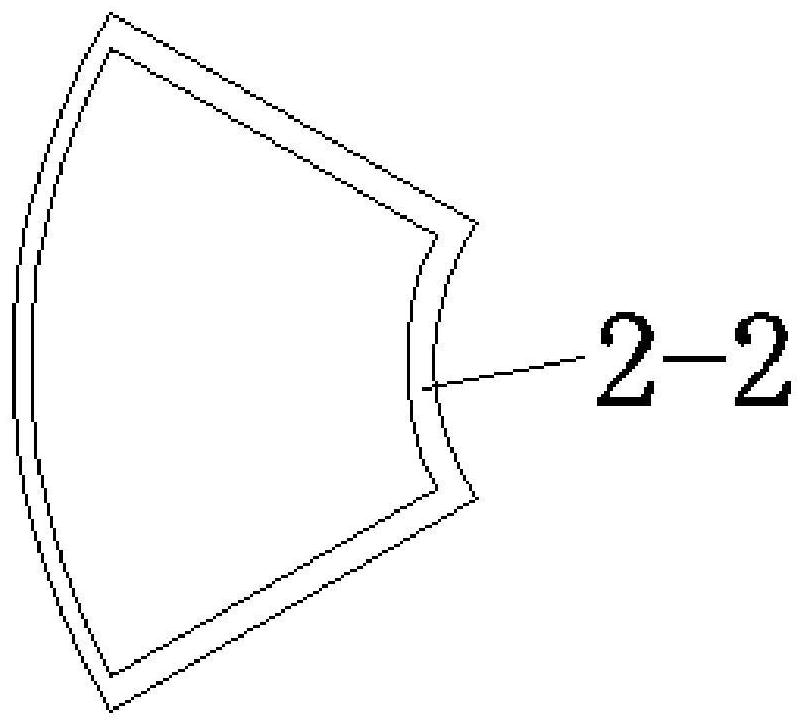

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that the cross-sectional shape of the mycelium growth chamber 2 is fan-shaped.

[0027] The cross-section of the hyphae development chamber in this embodiment is as follows: image 3 As shown, a plurality of mycelium development chambers 2 are arranged along the circumference of the plant growth chamber 1, and the plurality of mycelium development chambers 2 form a circular ring.

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the housing 6 is arranged on the upper surface of the base 4, the axial direction of the housing 6 is perpendicular to the upper surface of the base 4, and the housing 6 is set in the experimental control outside of barrel 3.

[0029] In this embodiment, the plant growth chamber, the mycelium development chamber, and the experimental control cylinder are set inside the casing to form a closed structure. In this embodiment, the material of the plant growth room, mycelium development room, experimental control cylinder and shell are all glass plates, which can enable the experimenters to quickly grasp the internal conditions of the equipment, and can also reduce the influence of external environmental factors on the system, so that the interior can be continuously maintained. stable environment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com