Beverage cold turbidity preventing method

A technology of cold turbidity and beverage, which is applied in the field of prevention and treatment of beverage cold turbidity, which can solve the problems of beverage flavor decline, residual formaldehyde, food safety threats, etc., and achieve the effect of preventing cold turbidity and extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

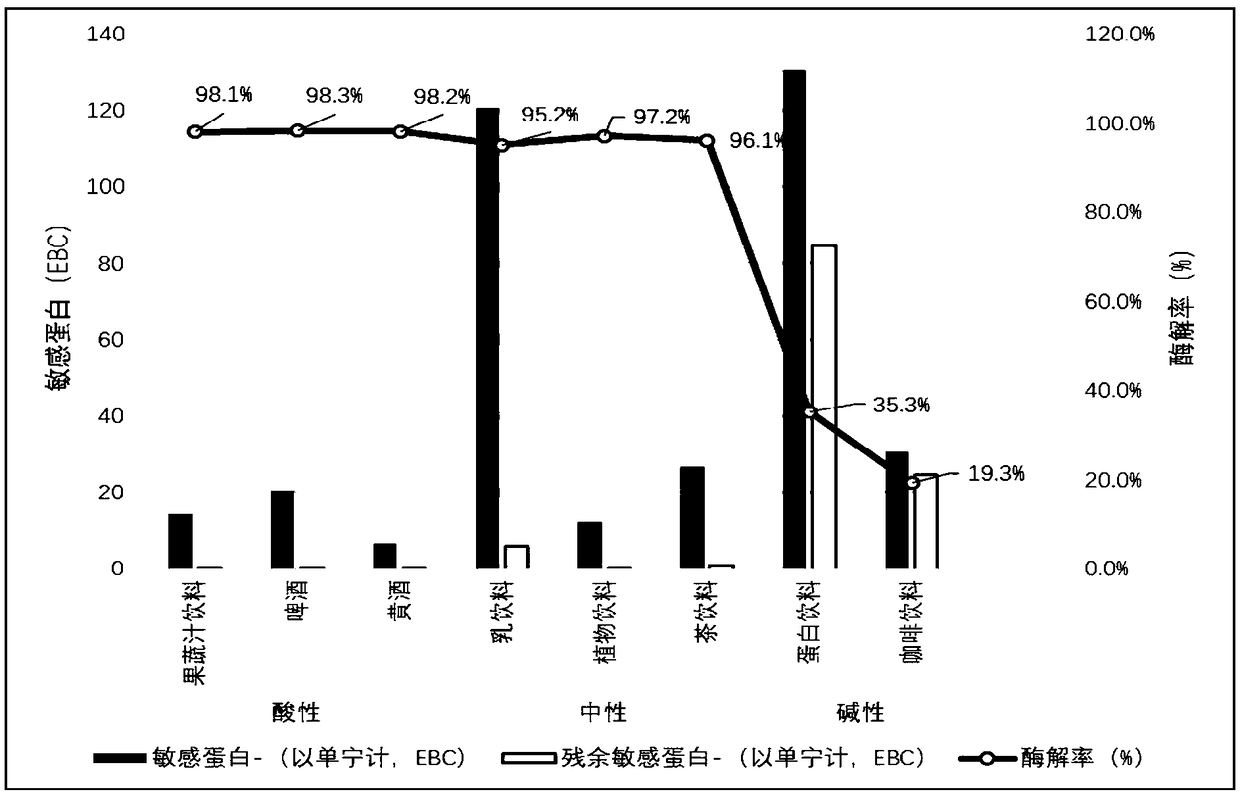

[0020] Purchase fruit and vegetable juice beverages (acidic), beer (acidic), rice wine (acidic), milk beverages (neutral), plant beverages (neutral), tea beverages (neutral) added with protein and polyphenols from the market , protein drink (alkaline), coffee drink (alkaline), and determine the sensitive protein in it. Determination of sensitive protein refers to the method in "Introduction to a Rapid Method for Determination of Beer Turbidity Sensitive Protein" ("Brewing" Volume 29, Issue 4, July 2002). Specific proline endonuclease and dipeptidyl peptidase IV (DPPIV) were purchased from the market.

[0021] Enzyme preparations are added to various beverages. The effective enzymatic hydrolysis component in the enzyme preparation is specific proline endonuclease, and the enzymatic hydrolysis addition amount of specific proline endonuclease is 10ppm; Afterwards, the sensitive protein was determined, and the determination time was the initial time point and the 45th day of enzy...

Embodiment 2

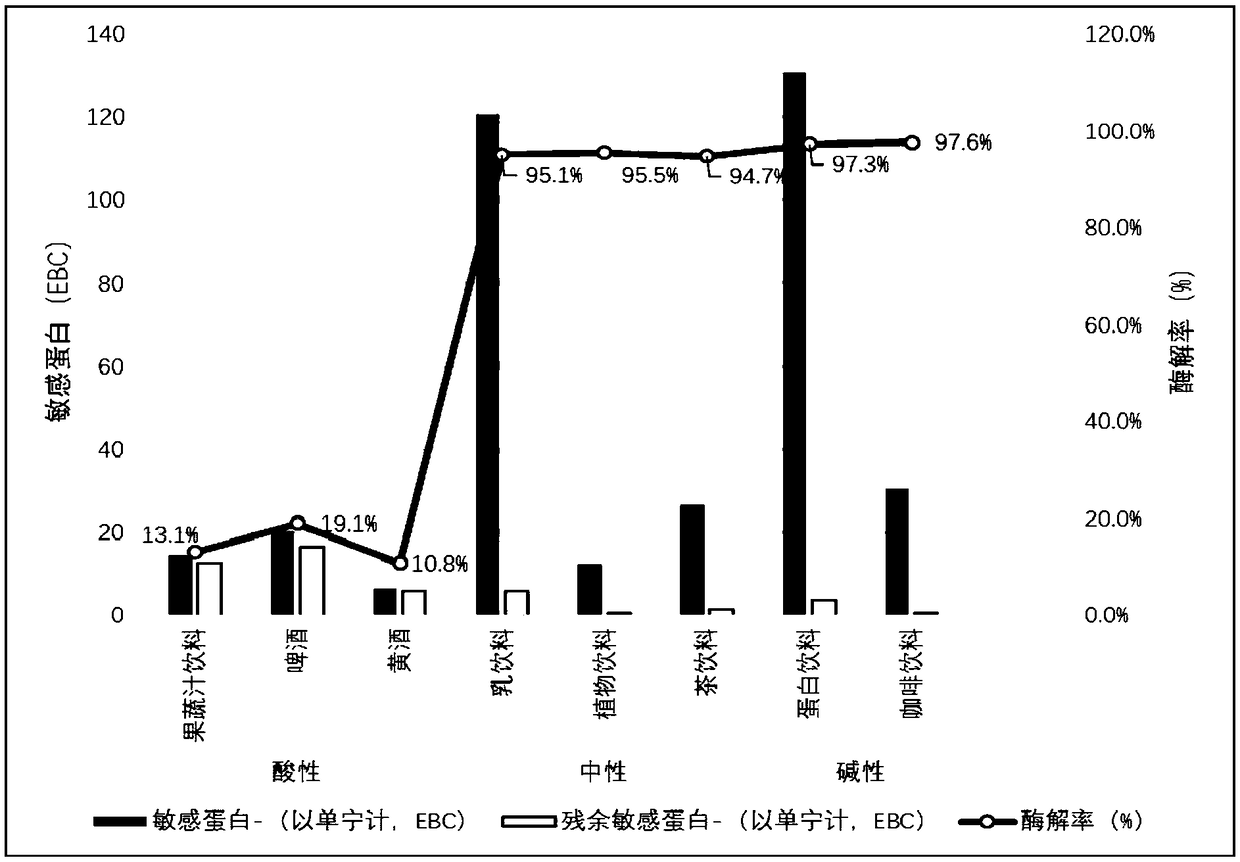

[0024] Purchase fruit and vegetable juice beverages (acidic), beer (acidic), rice wine (acidic), milk beverages (neutral), plant beverages (neutral), tea beverages (neutral) added with protein and polyphenols from the market , protein drink (alkaline), coffee drink (alkaline), measure sensitive protein wherein, the assay method of sensitive protein is with reference to the reference document described in embodiment 1.

[0025] Add enzyme preparations to various beverages respectively. The effective enzymatic hydrolysis component in the enzyme preparation is dipeptidyl polypeptide enzyme IV (DPPIV), and the enzymatic hydrolysis addition amount of dipeptidyl polypeptide enzyme IV is 10ppm; Sensitive proteins were determined, and the determination time was the initial time point and the 45th day of enzymatic hydrolysis. The result is as figure 2 shown.

[0026] From the results, it was found that the hydrolysis rate of dipeptidyl polypeptidease IV (DPPIV) for the alkaline beve...

Embodiment 3

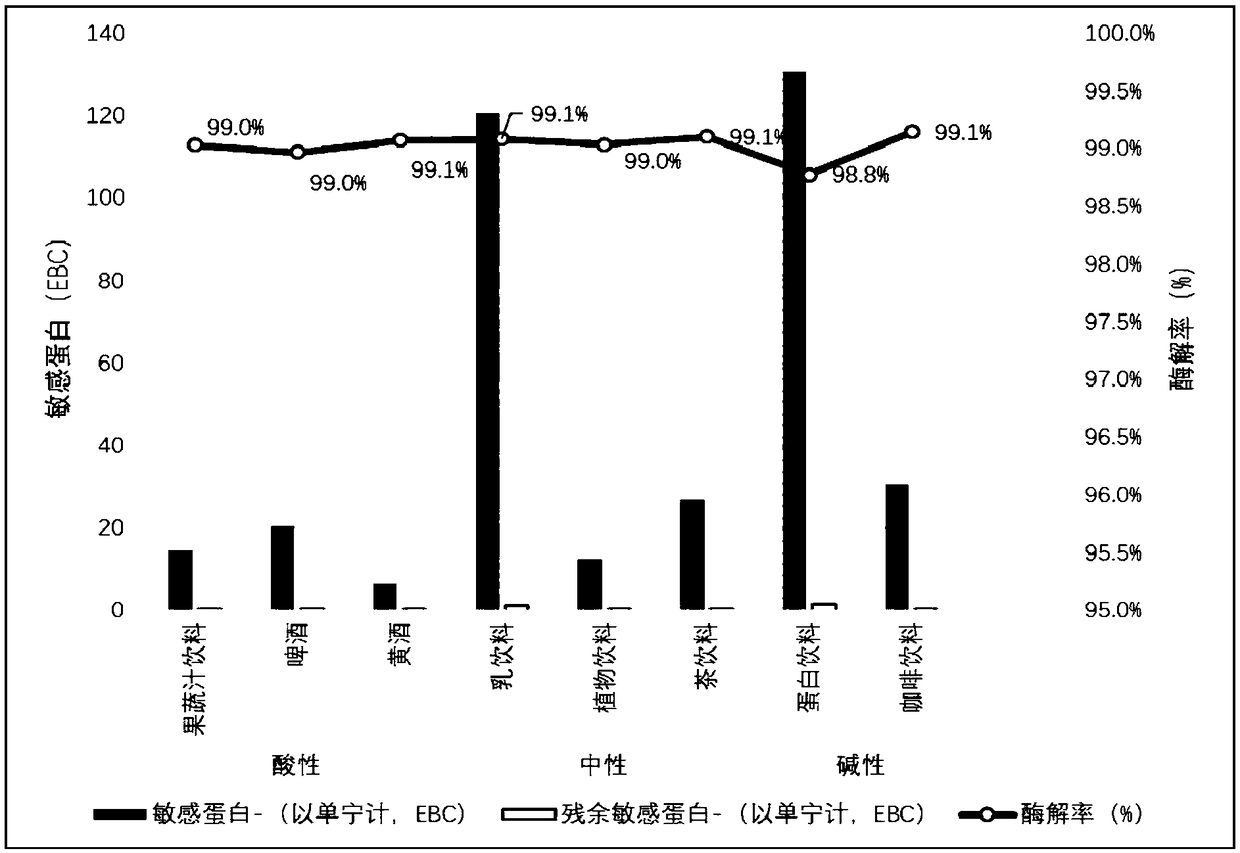

[0028] Purchase fruit and vegetable juice beverages (acidic), beer (acidic), rice wine (acidic), milk beverages (neutral), plant beverages (neutral), tea beverages (neutral) added with protein and polyphenols from the market , protein drink (alkaline), coffee drink (alkaline), measure sensitive protein wherein, the assay method of sensitive protein is with reference to the reference document described in embodiment 1.

[0029] Enzyme preparations were added to various beverages, and the effective enzymolysis components in the enzyme preparation were specific proline endonuclease and dipeptidyl polypeptidease IV (DPPIV). Enzymatic hydrolysis, after enzymatic hydrolysis, the sensitive protein was measured, and the measurement time was the initial time point and the 45th day of enzymatic hydrolysis. The result is as image 3 shown.

[0030] From the results, it was found that by adding 10 ppm of specific proline endonuclease and dipeptidyl polypeptidease IV (DPPIV), the enzymol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com