A flexible cabinet entry system and cabinet entry method for expanded cut tobacco cooked silk cabinet

A technology for expanding shredded tobacco and cooked shredded tobacco, which is applied in the fields of tobacco, cigarette manufacturing, and application, and can solve problems such as inability to complete laying work, low utilization rate, mixed batches or mixed numbers, etc., so as to improve equipment utilization and utilization The effect of high efficiency and smooth production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

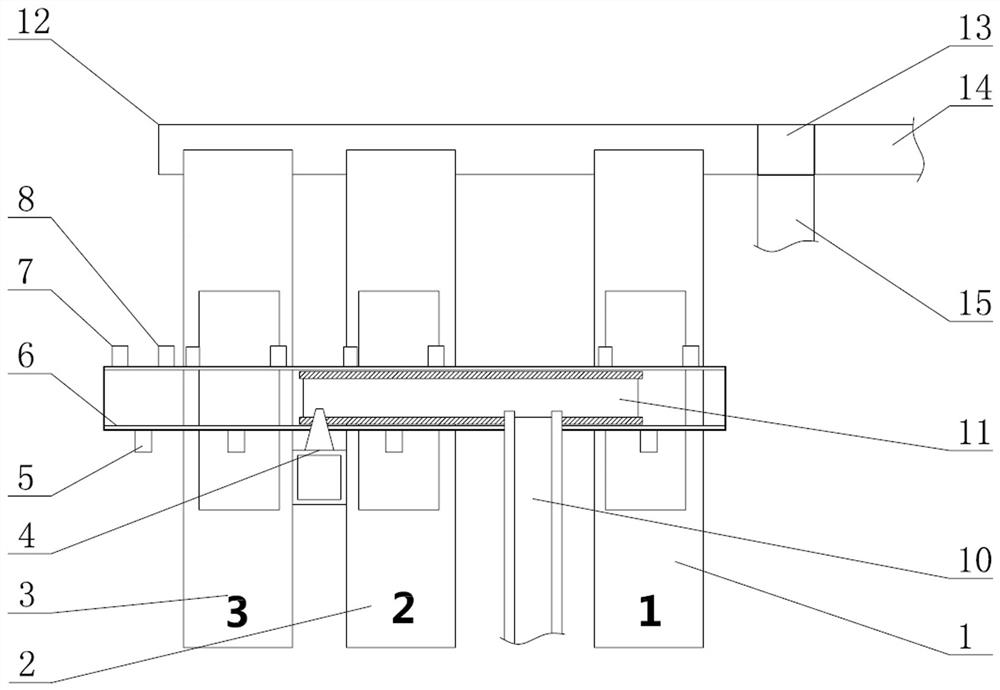

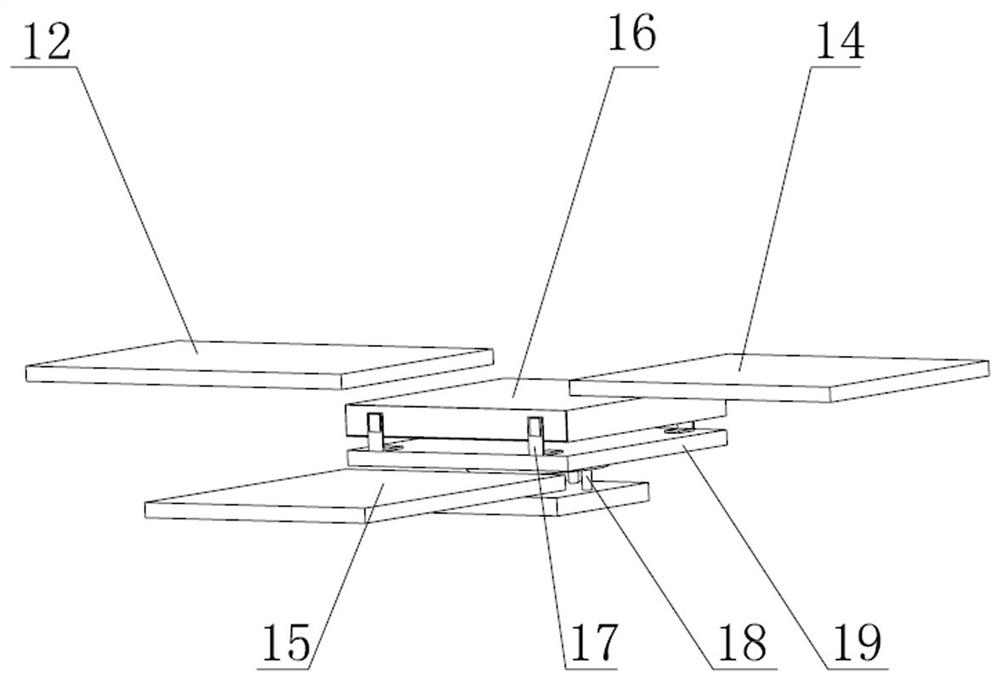

[0036] The invention discloses a flexible cabinet entry system and a cabinet entry method for expanded shredded tobacco cooked silk cabinets, such as figure 1 As shown, the flexible cabinet feeding system includes a central processing module and three cooked silk cabinets arranged side by side. The bottom of each cooked silk cabinet is equipped with a discharge mechanism. The upper slide is connected with a laying crane 11 for laying materials to the cooked silk cabinet. Positioning modules are provided on the driving guide rail 6 corresponding to the positions of each cooked silk cabinet. The bottom of the laying crane 11 is provided with induction blocks corresponding to the front and rear of the positioning module. There is a conveying mechanism for transporting the expanded silk from abroad on the top of the laying vehicle 11, and three cooked silk cabinets are sequentially No. 1 cabinet 1, No. 2 cabinet 2 and No. 3 cabinet 3 from right to left, and the right end of No. 1 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com