Joint cavity injection preparation and application thereof

A technology for injection preparations and joint cavity, which is applied in the direction of medical preparations containing active ingredients, bone diseases, organic active ingredients, etc. It can solve the problems of not easy to degrade, affect the use effect, and slow removal, and achieve good biocompatibility and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

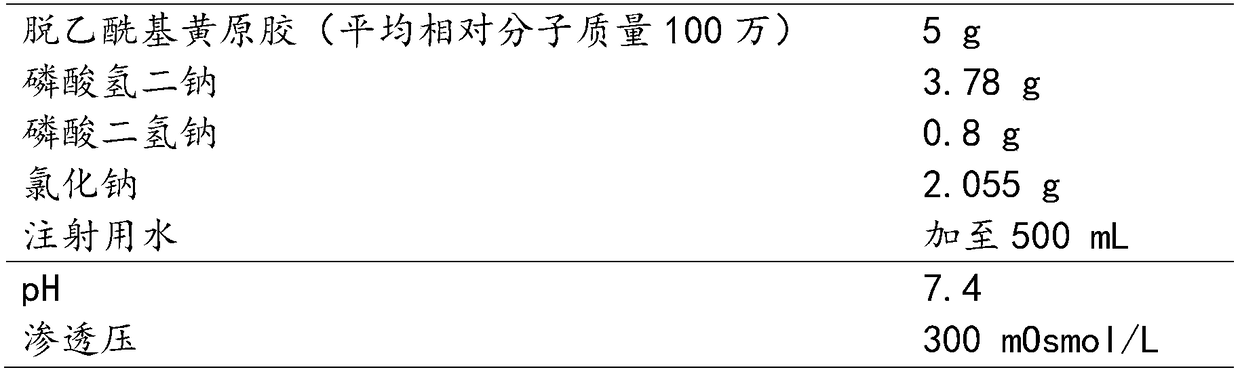

Embodiment 1

[0029] The preparation method of deacetylated xanthan gum:

[0030] Take 10g of xanthan gum with a molecular weight of 3 million and fully dissolve it in 1000mL of water, adjust the pH to 11, stir at a temperature of 50°C for 0.5h, adjust the pH to 2.0, place it at 0.1MPa for 20min, adjust the pH to 7.0 after cooling, use Precipitate with ethanol, and dry the precipitated product under reduced pressure at 40°C for 24h, to obtain.

[0031] The Mw of the deacetylated xanthan gum detected by multi-angle laser is 1 million, and the hydroxylamine hydrochloride colorimetric method is used to detect that there is no acetyl group in its structure.

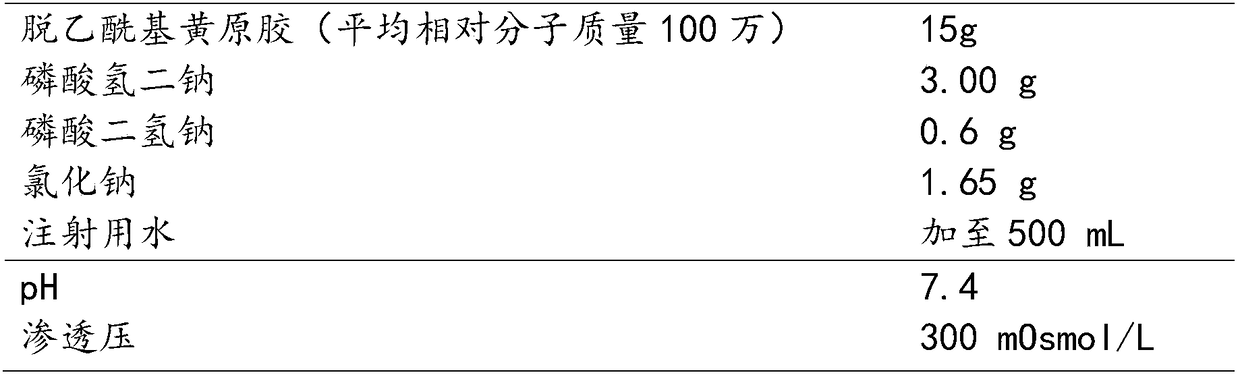

Embodiment 2

[0033] The preparation method of deacetylated xanthan gum:

[0034] Take 20g of xanthan gum with a molecular weight of 3 million and fully dissolve it in 1000mL of water, adjust the pH to 11, stir at 60°C for 2 hours, adjust the pH to 3.0, place it at 0.1MPa for 30 minutes, adjust the pH to 7.0 after cooling, and use ethanol Precipitate, and the precipitated product is dried under reduced pressure at 40°C for 24h to obtain it.

[0035] The Mw of the deacetylated xanthan gum detected by multi-angle laser is 2 million, and the hydroxylamine hydrochloride colorimetric method is used to detect that there is no acetyl group in its structure.

Embodiment 3

[0037] The preparation method of deacetylated xanthan gum:

[0038] Take 30g of xanthan gum with a molecular weight of 5 million and fully dissolve it in 1000mL of water, adjust the pH to 12, stir at a temperature of 50°C for 1 hour, adjust the pH to 5.0, place it at 0.1MPa to react for 20 minutes, adjust the pH to 7.0 after cooling, and use ethanol Precipitate, and the precipitated product is dried under reduced pressure at 40°C for 24h, to obtain.

[0039] The Mw of the deacetylated xanthan gum detected by multi-angle laser is 4 million, and the hydroxylamine hydrochloride colorimetric method is used to detect that the structure does not contain acetyl groups.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com