Immersion cleaning system and method for treating construction waste with citric acid

A technology for construction waste and citric acid, which is applied in construction waste recycling, solid waste removal, recycling technology and other directions, can solve the problems of cumbersome construction waste treatment procedures, high pre-treatment requirements, and long treatment cycles, and can shorten the pre-treatment process. effect of time, perfect pretreatment and high degree of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0080]

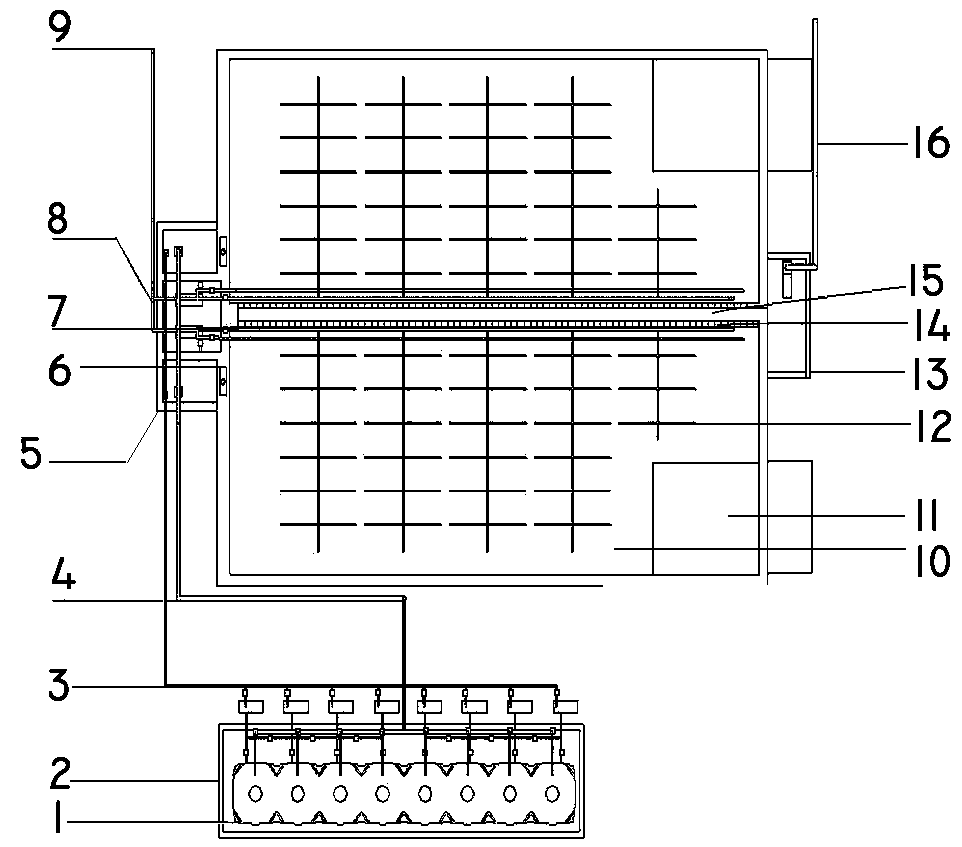

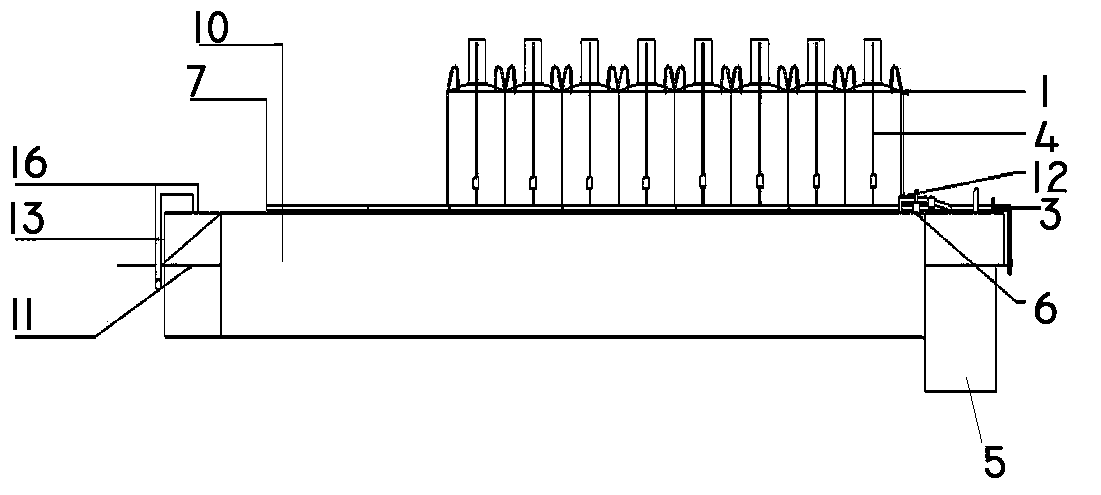

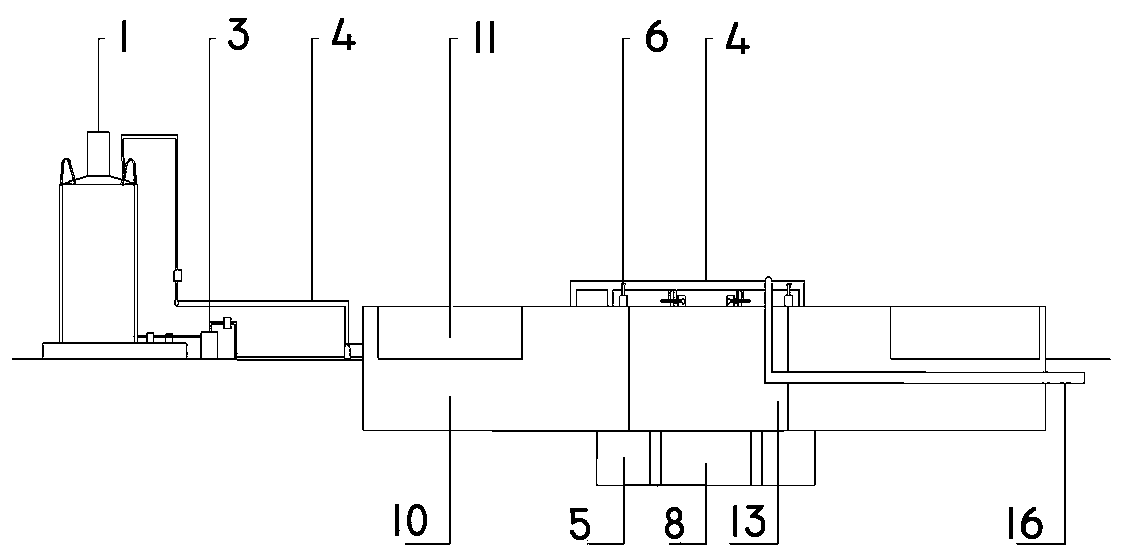

[0081] It can be seen from the above table 1 that a citric acid immersion system and method for treating construction waste provided by the present invention has a very good treatment effect on construction waste with an initial concentration of hexavalent chromium above 500 mg / kg. Among them, the liquid medicine mixing tank 1 used in the immersion system, the reaction pool 10, the number of pumps in the pump pool 8, the length of the medicine distribution pipeline 7, the pipe material of the medicine feeding pipe 3, the particle size of construction waste, citric acid and ferrous chloride The compounding ratio, chemical concentration, chemical and construction waste solid-liquid, and the number of drug inlet valves on the drug distribution pipeline 7 can be flexibly adjusted according to factors such as actual processing capacity and processing site. The addition or reduction of part of the reaction pool 10 with a similar main structure is regarded as a modificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com