A multifunctional ball end milling cutter

A ball-end milling cutter, multi-functional technology, applied in the direction of milling cutters, milling cutting blades, milling machine equipment, etc., can solve the problems that affect the overall performance of ball-end milling cutters, poor processing surface quality, cutting edge wear, etc., to improve processing Good surface quality, good surface quality and light cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

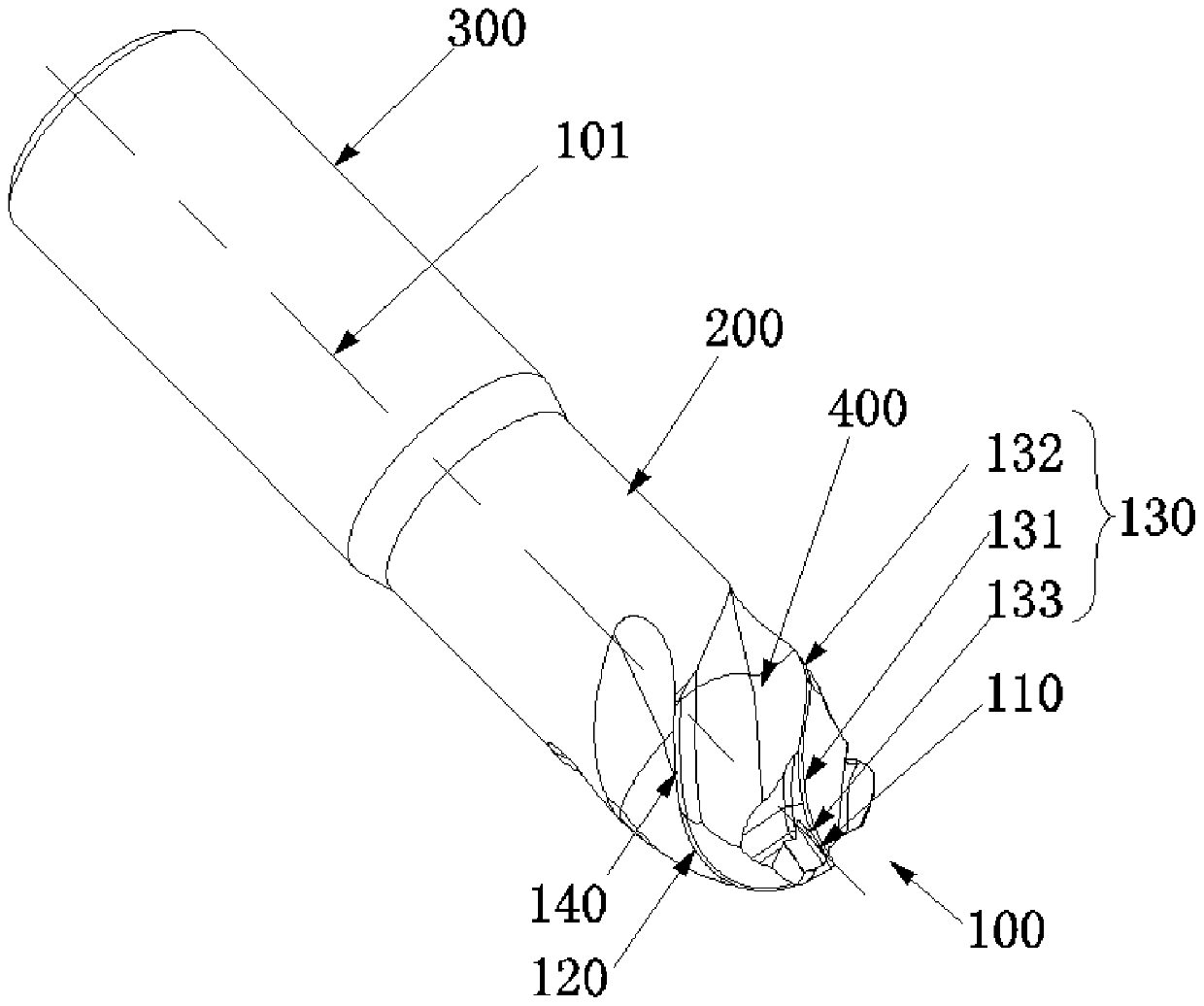

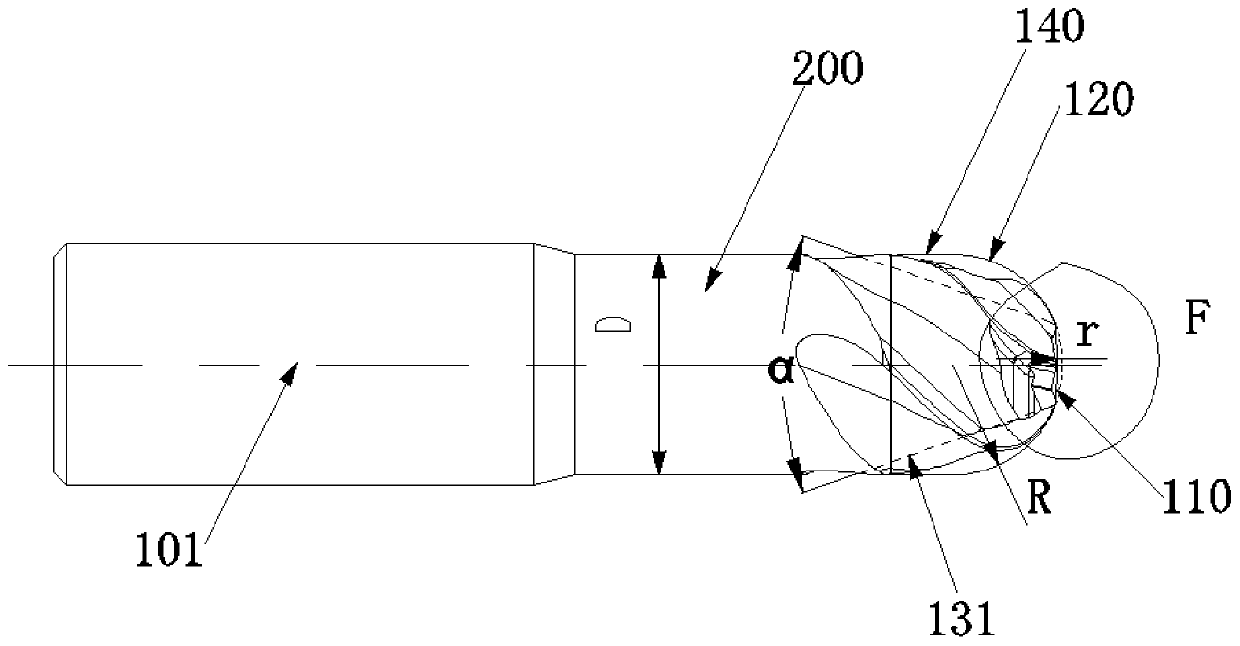

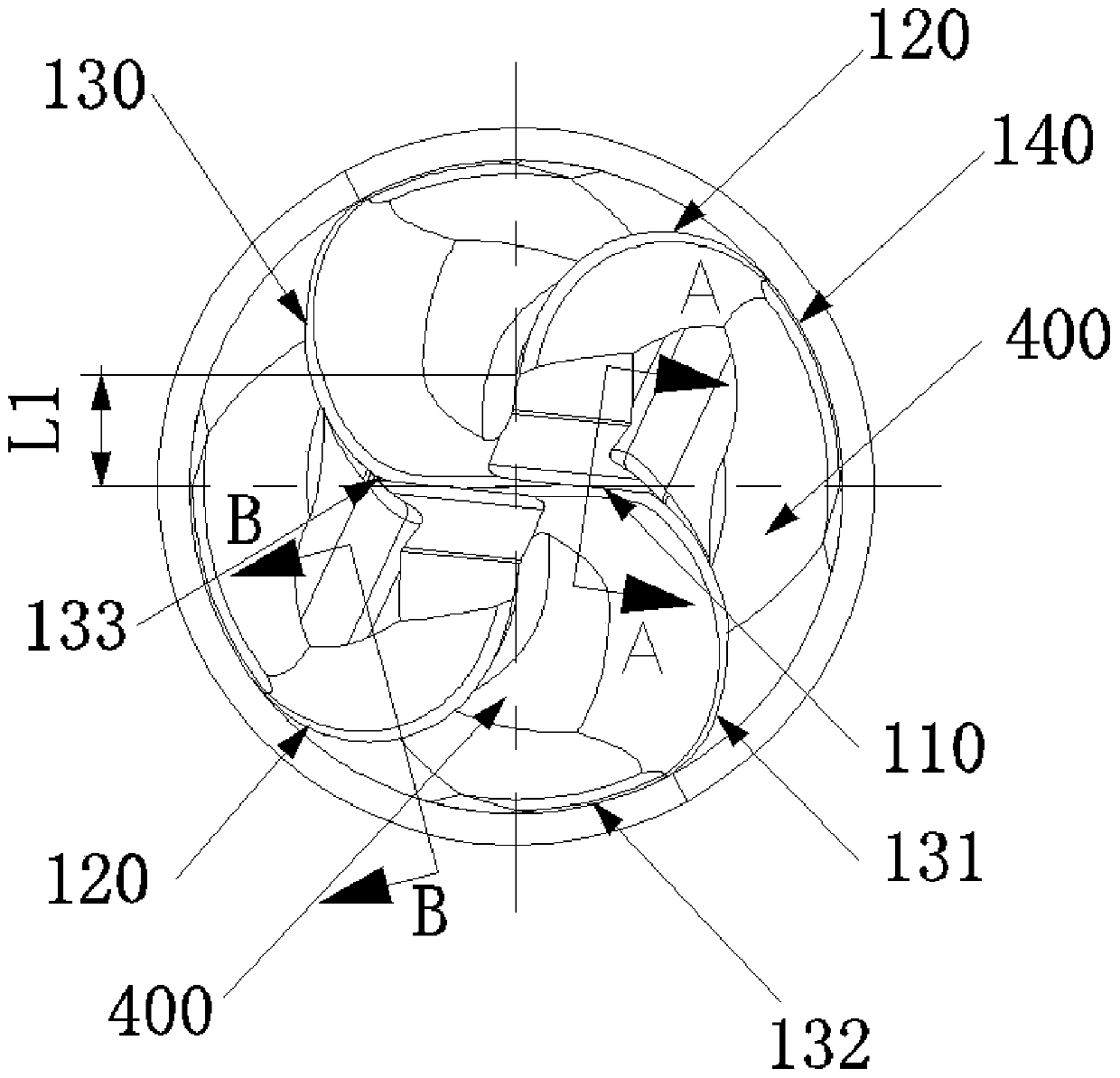

[0041] like Figure 1 to Figure 6 As shown, the multifunctional ball end milling cutter of the present embodiment includes a cutting part 100, a loading and unloading part 300, and a connecting part 200 for connecting the cutting part 100 and the loading and unloading part 300. The cutting part 100 has a central axis 101, and the cutting part 100 includes An inner spherical cutting edge 110 and at least one pair of outer spherical cutting edges 120, the inner spherical cutting edge 110 intersects with the central axis 101 and is rotationally symmetrical about the central axis 101, two outer spherical cutting edges 120 in each outer spherical cutting edge 120 are about the center The axis 101 is rotationally symmetrical, and there is a certain radial distance between the outer spherical cutting edge 120 and the central axis 101, the spherical surface formed by the inner spherical cutting edge 110 rotating about the central axis 101 and the spherical surface formed by the outer s...

Embodiment 2

[0052] like Figure 7 to Figure 9 As shown, the multifunctional milling cutter of the present embodiment is basically the same as Embodiment 1, and the difference is only in:

[0053] In this embodiment, the connecting edge 130 has the same structure as the outer spherical cutting edge 120 , and both are rotationally symmetrical about the central axis 101 . That is to say, the connecting edge 130 is milled in the same way as the outer spherical cutting edge 120 . The chip flutes 400 are formed by the area between the connecting edge 130 and the outer spherical cutting edge 120 , and the connecting edge 130 has the same structure as the outer spherical cutting edge 120 , so the four chip flutes 400 have the same structure. That is, in this embodiment, the cutting edge is divided into one inner spherical cutting edge 110 and four outer spherical cutting edges 120 . There is a transitional cutting edge 150 with a smooth transition between the connecting edge 130 and the inner s...

Embodiment 3

[0056] like Figure 10 and Figure 11 As shown, in the multifunctional ball end milling cutter of this embodiment, the cutting part 100 includes an inner ball cutting edge 110 and an outer ball cutting edge 120, the inner ball cutting edge 110 intersects the central axis 101, and the intersection point cuts the inner ball The cutting edge 110 is divided into two sections, the length of one section is longer than the length of the other section. There is a certain radial distance between the outer spherical cutting edge 120 and the central axis 101; The spherical surface formed by the rotation of the spherical cutting edge 120 about the central axis 101 intersects. The spherical surface radius of the inner spherical cutting edge 110 is r, and the spherical surface radius of the outer spherical cutting edge 120 is R, satisfying: 5R≤r≤15R.

[0057] In this embodiment, only one end of the inner ball cutting edge 110 has a connecting edge 130 between the connecting portion 200, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com