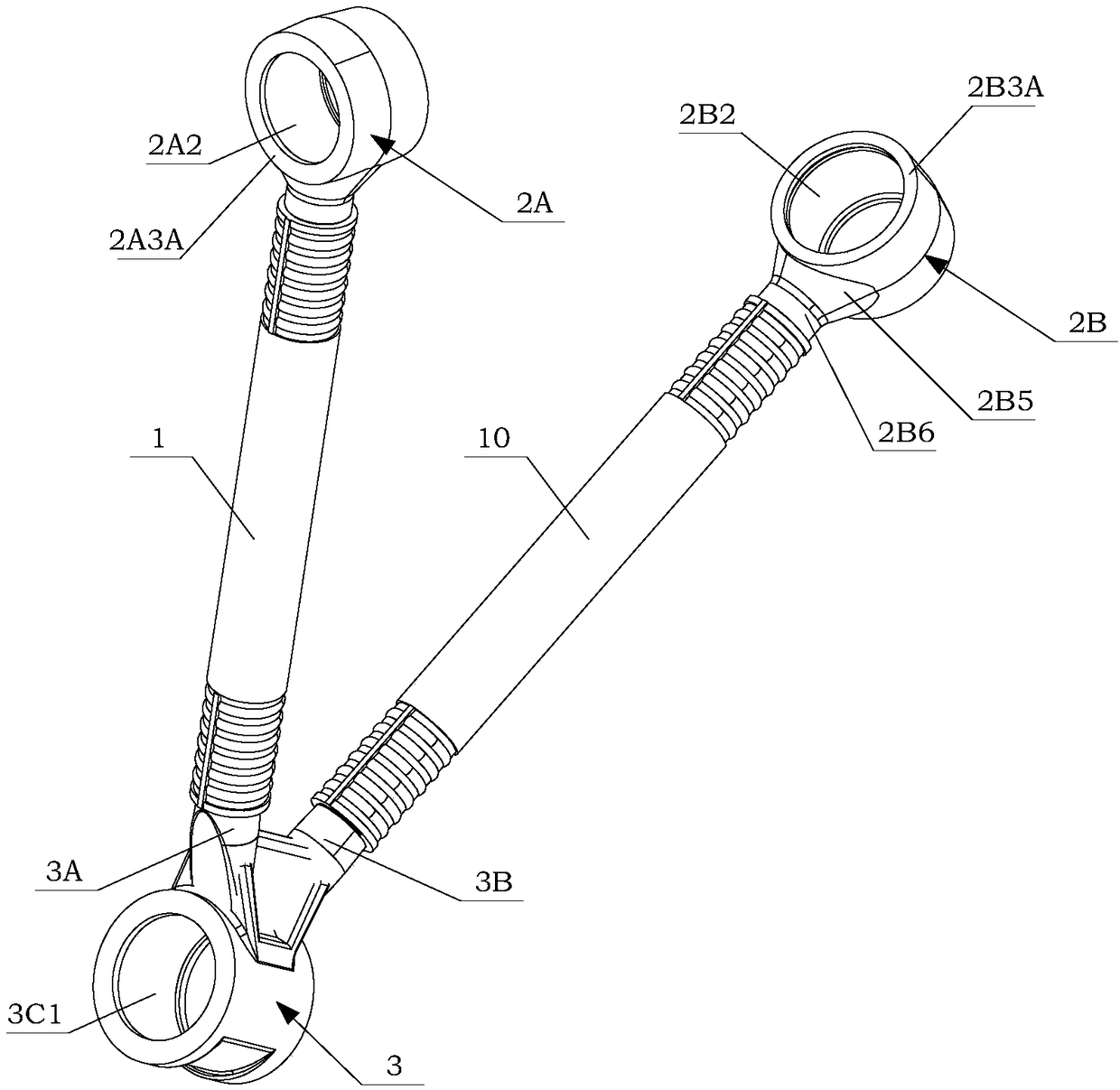

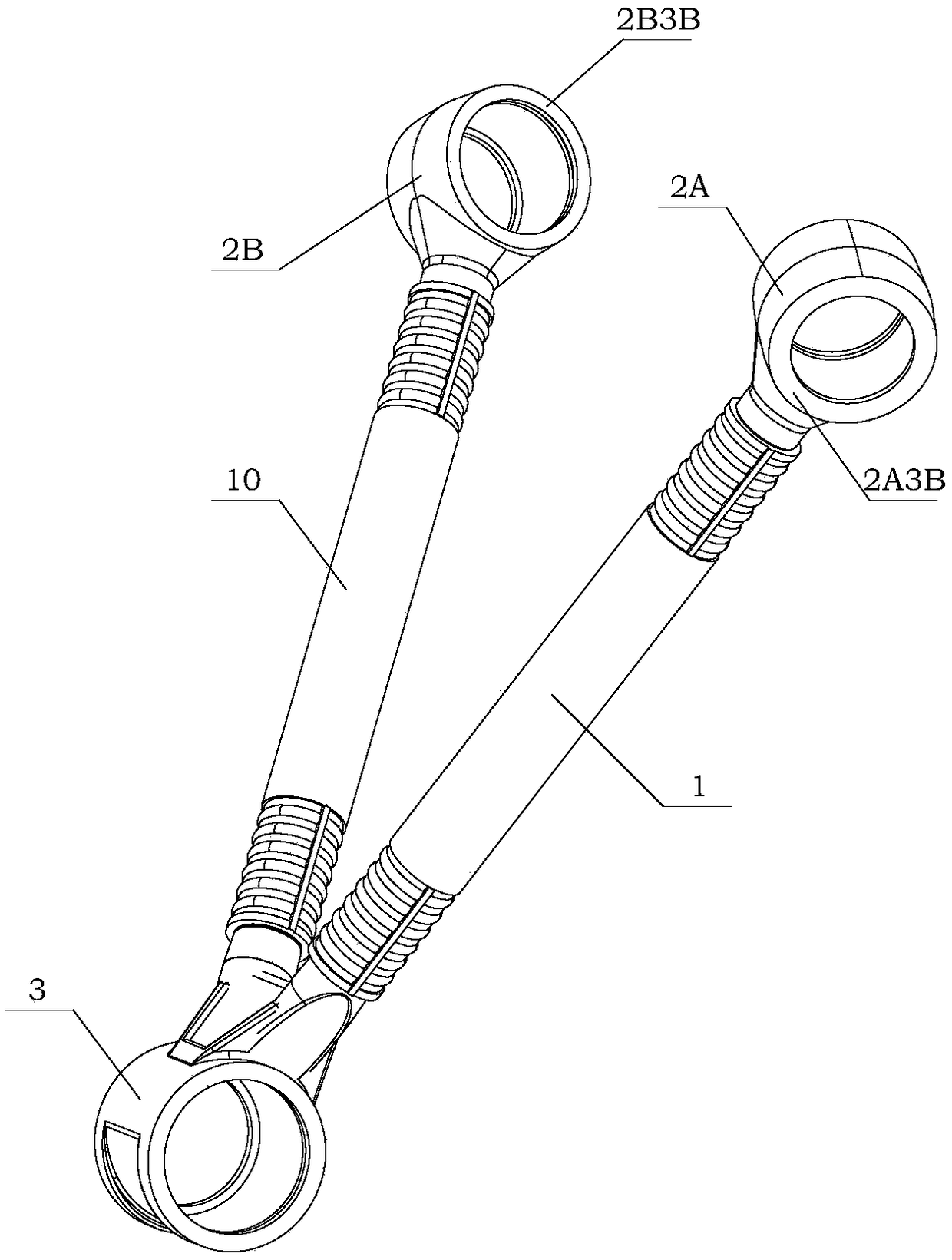

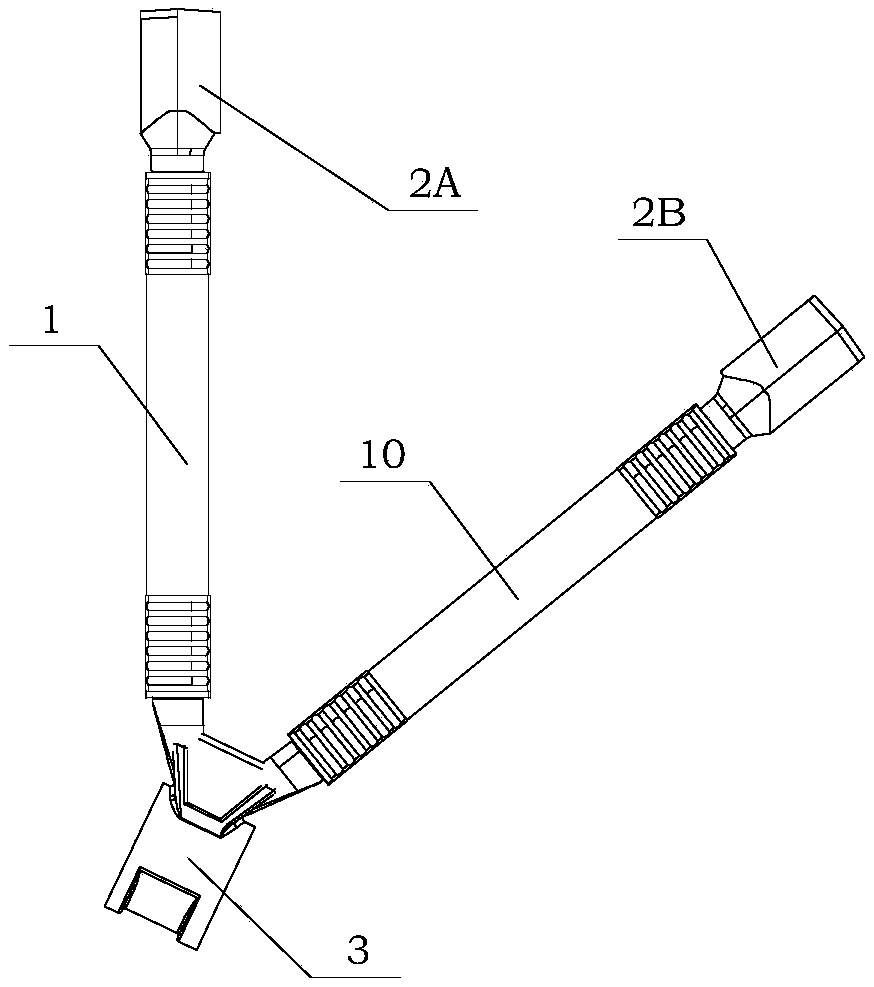

Aluminum alloy split V-shaped thrust rod and preparation method and hot riveting assembly method thereof

A technology of aluminum alloy and thrust rod, which is applied in metal processing equipment, forging/pressing/hammer devices, forging presses, etc., can solve the problems of heavy thrust rod weight and poor lightweight effect, and achieve high degree of automation and high yield , high performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0125] The composition of thrust rod among the embodiment one is:

[0126] the element

Amount (mass percentage, wt%)

Si

1.2

Mg

1.2

Fe

0.6

Cu

5.5

mn

0.5

Cr

0.08

Ni

0.05

Zn

0.20

Ti

0.15

Zr

0.05

Sr

0.03

Er

0.005

Ce

0.01

Al

balance, and unavoidable impurities.

[0127] Overall length L of casing 1 1 =810mm, inner radius r of casing 1 1A =30mm; the maximum outer radius r of the bellows section of A ball head 2A 2A1 = 30mm, the maximum outer radius of the bellows section of the V-shaped ball head 3 is 30mm; the radius of the neck arc section (2A6, 2B6) of the A ball head is The major radius of the elliptical segments (2A5, 2B5) is Oa=135mm, and the minor radius is Ob=90mm.

[0128] The sleeve preparation process is hot extrusion molding, and the process is as follows:

[0129] Step 101, preparing an aluminum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com