High-performance multistage water-purifying filter element

A water purification filter element with high efficiency technology, applied in the field of water purification, can solve the problems of single function and high cost of use, and achieve the effect of simple overall structure and good cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

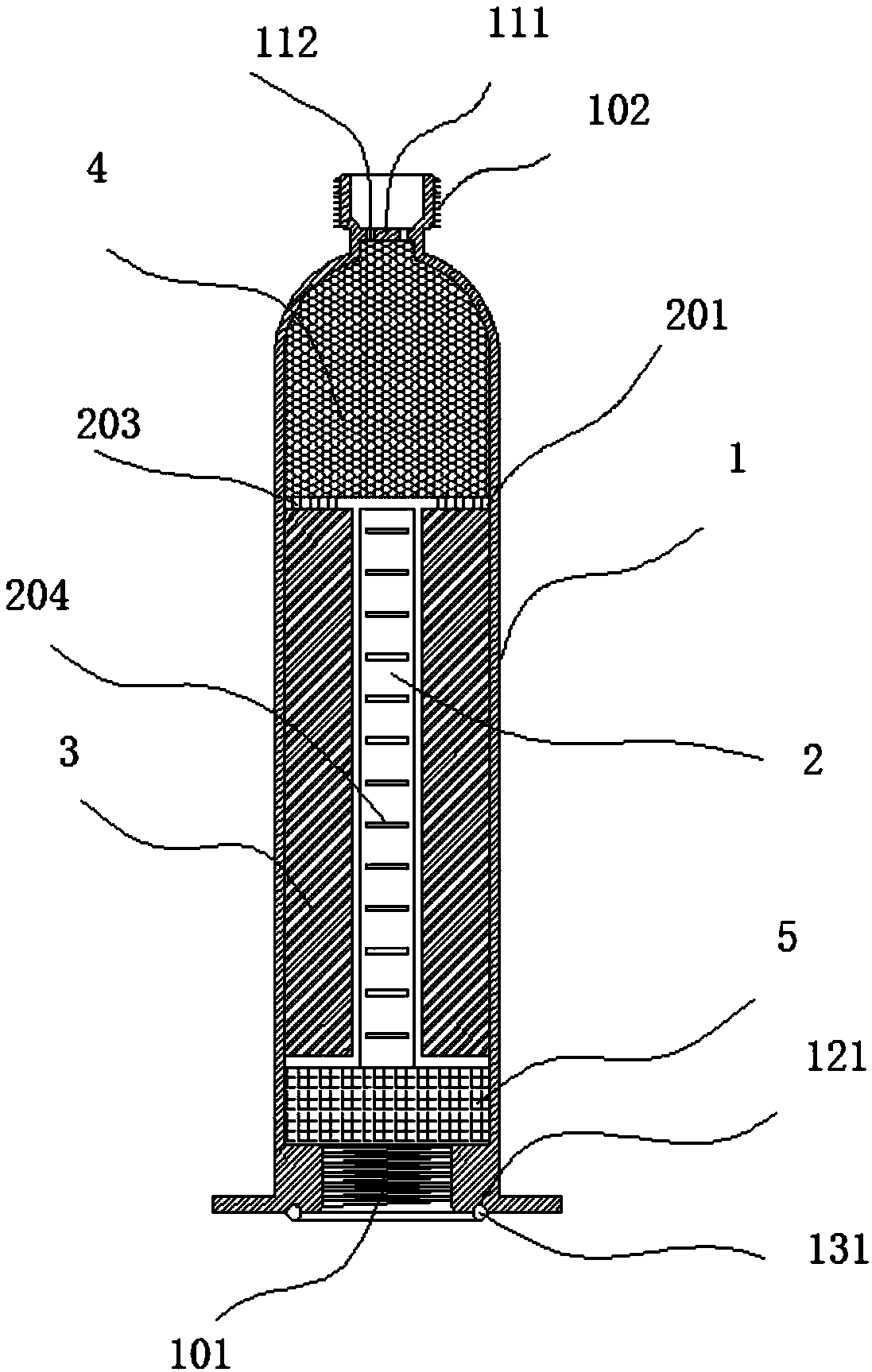

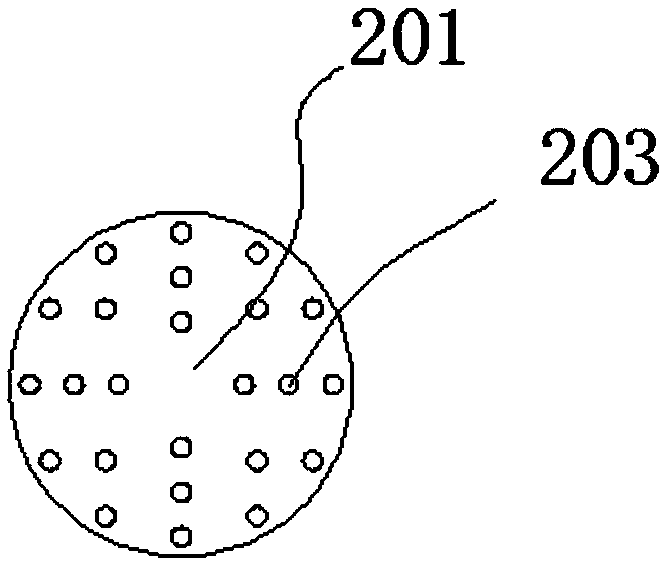

[0051] Such as Figure 1 to Figure 6 A high-efficiency multi-stage water purification filter element shown includes a housing 1, an opening 101 is provided at the lower end of the housing 1, and a threaded pipe portion 102 for connecting pipelines is provided at the upper end, and an inner pipe 2 is provided inside the housing 1 , the upper and lower ends of the inner tube 2 are injection-molded with a baffle 201, the baffle 201 fits the inner wall of the outer shell 1, and forms a seal with the outer shell 1, and the lower baffle 201 is provided with a Connected to the water inlet hole 202 of the inner pipe 2, the outer wall of the baffle plate 201 above is evenly distributed with water outlet holes 203 for upward water outlet, and the outer wall of the inner pipe 2 is evenly distributed with water outlet grooves 204. A PP cotton filter element 3 is sheathed on the outside of the inner tube 2, and activated carbon 4 is filled inside the shell 1 at the top of the upper baffle ...

Embodiment 2

[0068] Substantially the same as Example 1, the only difference is that the preparation method of the activated carbon comprises the following steps, and the parts are parts by weight:

[0069] (1) Wash pomelo peel, dry at 105° C. for 6 hours, pulverize, and pass through a 40-mesh sieve to obtain pomelo peel coarse powder;

[0070] (2) Mix pomelo peel coarse powder and activator at a solid-to-liquid ratio of 1g: 4mL, impregnate at normal pressure for 120 minutes, then immerse in 80MPa for 30 minutes, filter with 200 mesh filter cloth, and the obtained solid is impregnated pomelo peel coarse powder ;

[0071] (3) Put the impregnated pomelo peel coarse powder into a tube furnace, raise the temperature to 450° C. at 10° C. / min under nitrogen protection, and keep the temperature at 450° C. for 80 minutes to obtain a carbonized material;

[0072] (4) Take out the carbonized material, mix it with the acid solution according to the solid-to-liquid ratio of 1g: 4mL, soak it under nor...

Embodiment 3

[0076] Substantially the same as Example 1, the only difference is that the preparation method of the activated carbon 4 comprises the following steps, and the parts are parts by weight:

[0077] (1) Wash pomelo peel, dry at 105° C. for 6 hours, pulverize, and pass through a 40-mesh sieve to obtain pomelo peel coarse powder;

[0078](2) Mix pomelo peel coarse powder and activator at a solid-to-liquid ratio of 1g: 4mL, impregnate at normal pressure for 120 minutes, then immerse in 80MPa for 30 minutes, filter with 200 mesh filter cloth, and the obtained solid is impregnated pomelo peel coarse powder ;

[0079] (3) Put the impregnated pomelo peel coarse powder into a tube furnace, raise the temperature to 450° C. at 10° C. / min under nitrogen protection, and keep the temperature at 450° C. for 80 minutes to obtain a carbonized material;

[0080] (4) Take out the carbonized material, mix it with the acid solution according to the solid-to-liquid ratio of 1g: 4mL, soak it under no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com