Ceramic tile adhesive

A technology of adhesive glue and ceramic tiles, which is applied in the field of chemical building materials, can solve the problems that affect the aesthetic feeling of soft porcelain paving, lack of soft porcelain adhesive, and weak adhesion, etc., and achieve simple construction and operation, firm adhesion, and strong anti-pan The effect of alkaline capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

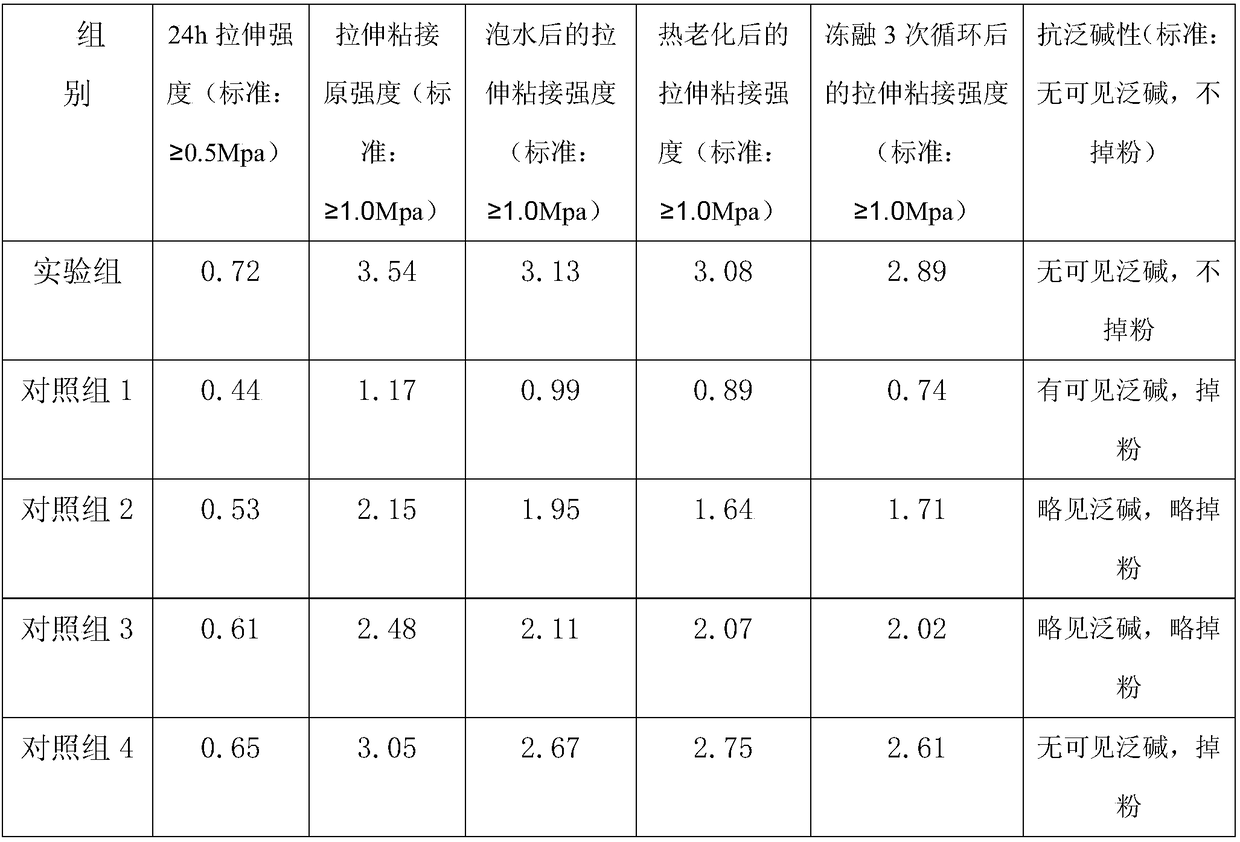

Examples

Embodiment 1

[0021] A tile adhesive, which is mainly made by mixing and stirring component A and component B at a weight ratio of 4:1; the component A includes the following raw material components in parts by weight: 0.02 parts of simethicone, cellulose 0.2 part of ether, 0.1 part of calcium formate, 50 parts of quartz sand and 20 parts of modified industrial inorganic powder; the B component is an acrylic acid emulsion; the modified industrial inorganic powder includes the following raw material components in parts by weight: 15 parts of bentonite , 5 parts of talcum powder and 1 part of silica lime;

[0022] The preparation method of the modified industrial inorganic powder is as follows: in parts by weight, weigh 15 parts of bentonite, 5 parts of talcum powder and 1 part of silica lime, and pulverize the weighed bentonite, talcum powder and silica lime for 150 Mesh sieve; after mixing bentonite and silica lime, add deionized water and stir evenly to obtain a slurry with a mass concentr...

Embodiment 2

[0025] A tile adhesive, which is mainly made by mixing and stirring component A and component B at a weight ratio of 4:1; the component A includes the following raw material components in parts by weight: 0.03 parts of defoaming agent, cellulose ether 0.4 parts, 0.2 parts of calcium formate, 55 parts of quartz sand and 25 parts of modified industrial inorganic powder; the B component is an acrylic acid emulsion; the modified industrial inorganic powder includes the following raw material components in parts by weight: 18 parts of bentonite, 7 parts of talcum powder and 1.5 parts of silica lime;

[0026] The preparation method of the modified industrial inorganic powder is as follows: in parts by weight, weigh 18 parts of bentonite, 7 parts of talcum powder and 1.5 parts of silica lime, and pulverize the weighed bentonite, talcum powder and silica lime for 150 Mesh sieve; after mixing bentonite and silica lime, add deionized water and stir evenly to obtain a slurry with a mass ...

Embodiment 3

[0029] A tile adhesive, which is mainly made by mixing and stirring component A and component B at a weight ratio of 4:1; the component A includes the following raw material components in parts by weight: 0.04 parts of polysiloxane, cellulose 0.5 part of ether, 0.3 part of calcium formate, 65 parts of quartz sand and 30 parts of modified industrial inorganic powder; the B component is an acrylic acid emulsion; the modified industrial inorganic powder includes the following raw material components in parts by weight: 20 parts of bentonite , 10 parts of talcum powder and 3 parts of silica lime;

[0030]The preparation method of the modified industrial inorganic powder is as follows: in parts by weight, weigh 20 parts of bentonite, 10 parts of talcum powder and 3 parts of silica lime, and pulverize the weighed bentonite, talcum powder and silica lime for 150 parts respectively. Mesh sieve; after mixing bentonite and silica lime, add deionized water and stir evenly to obtain a slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com