Porous cross-linked polystyrene light diffusing agent, PC light diffusing plate, and preparation methods of porous cross-linked polystyrene light diffusing agent and PC light diffusing plate

A technology of cross-linked polystyrene and light diffusing agent, applied in lighting and heating equipment, light sources, semiconductor devices of light-emitting elements, etc., can solve the problems of high luminous directivity and high color temperature of LEDs, achieve soft light and increase haze Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Co-porogen: a mixed solvent of toluene and low-density liquid paraffin, low-density liquid paraffin accounts for 0% of the total volume of the co-porogen, and the co-porogen accounts for 50% of the total volume of the mixed oil phase.

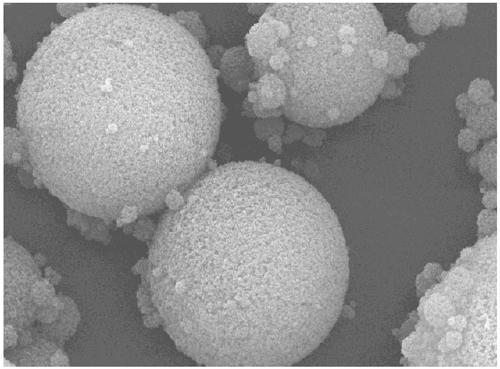

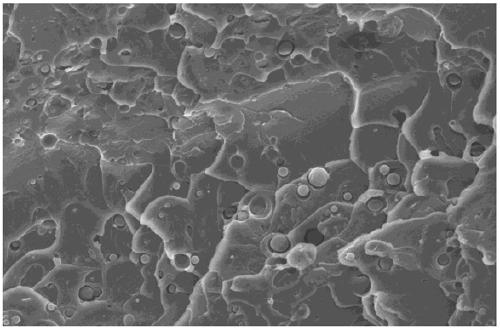

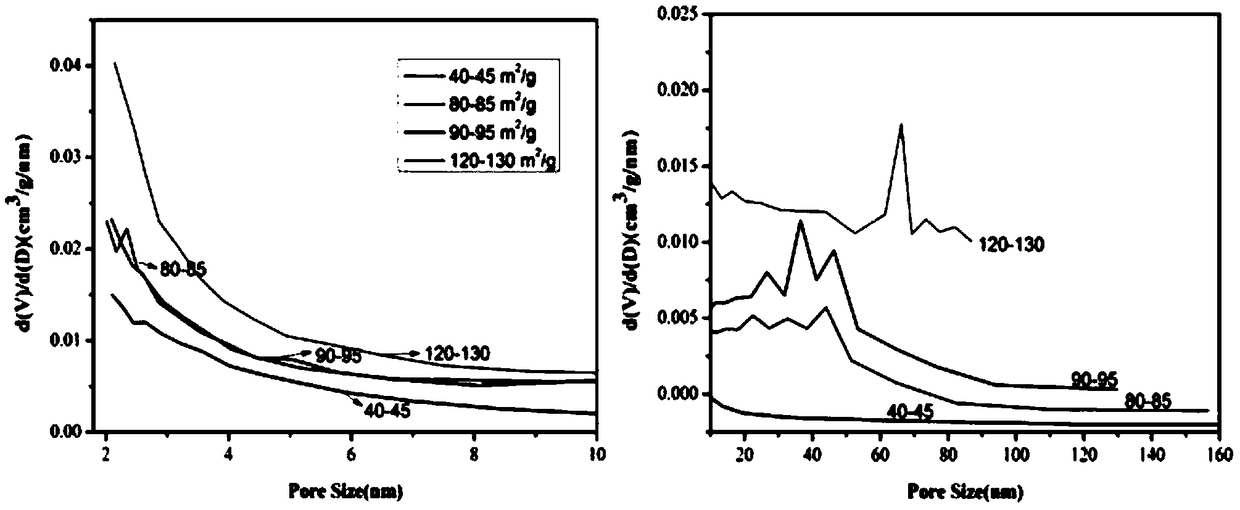

[0036] Emulsifier, co-emulsifier and deionized water (the mass fraction of emulsifier accounting for deionized water is 8%, and co-emulsifying agent accounts for 30% of the mass fraction of emulsifier) is added in the reactor, under ice-bath condition, mechanical Stir for 20 minutes, add styrene, divinylbenzene, and initiator (wherein the volume fraction of styrene and divinylbenzene is 3:2, and the mass fraction of the initiator in the mixed oil phase is 4%) into the beaker and sonicate for 10 minutes, Until it dissolves, add the co-porogen into the monomer mixture and disperse ultrasonically for 10 minutes until it is uniform to obtain a mixed oil phase. Put the mixed oil phase in a constant pressure funnel, drop it into the reactor,...

Embodiment 2

[0038] Co-porogen: a mixed solvent of toluene and low-density liquid paraffin. The low-density liquid paraffin accounts for 50% of the total volume of the co-porogen, and the co-porogen accounts for 50% of the total volume of the mixed oil phase.

[0039] Emulsifier, co-emulsifier and deionized water (the mass fraction of emulsifier accounting for deionized water is 8%, and co-emulsifying agent accounts for 30% of the mass fraction of emulsifier) is added in the reactor, under ice-bath condition, mechanical Stir for 20 minutes, add styrene, divinylbenzene, and initiator (wherein the volume fraction of styrene and divinylbenzene is 3:2, and the mass fraction of the initiator in the mixed oil phase is 4%) into the beaker and sonicate for 10 minutes, Until it dissolves, add the co-porogen into the monomer mixture and disperse ultrasonically for 10 minutes until it is uniform to obtain a mixed oil phase. Put the mixed oil phase in a constant pressure funnel, drop it into the rea...

Embodiment 3

[0041] Co-porogen: a mixed solvent of toluene and low-density liquid paraffin. The low-density liquid paraffin accounts for 70% of the total volume of the co-porogen, and the co-porogen accounts for 50% of the total volume of the mixed oil phase.

[0042]Emulsifier, co-emulsifier and deionized water (the mass fraction of emulsifier accounting for deionized water is 8%, and co-emulsifying agent accounts for 30% of the mass fraction of emulsifier) is added in the reactor, under ice-bath condition, mechanical Stir for 20 minutes, add styrene, divinylbenzene, and initiator (wherein the volume fraction of styrene and divinylbenzene is 3:2, and the mass fraction of the initiator in the mixed oil phase is 4%) into the beaker and sonicate for 10 minutes, Until it dissolves, add the co-porogen into the monomer mixture and disperse ultrasonically for 10 minutes until it is uniform to obtain a mixed oil phase. Put the mixed oil phase in a constant pressure funnel, drop it into the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com