Environment-friendly antibacterial package film easy to degrade

A packaging film, easily degradable technology, applied in the field of packaging materials, can solve problems such as white pollution, achieve the effect of easy degradation and improve antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

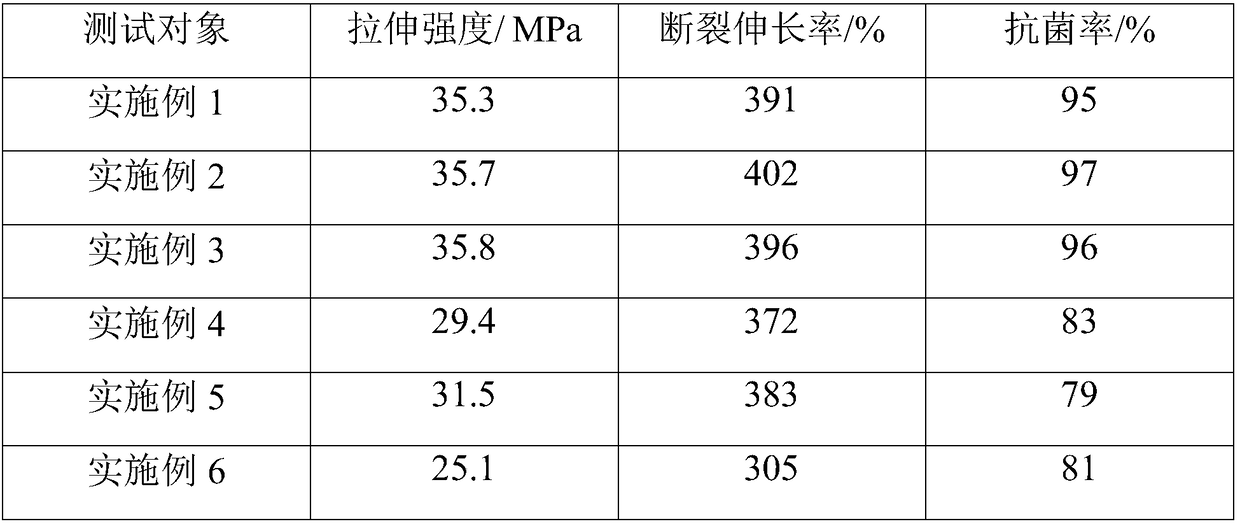

Embodiment 1

[0024] In this example, the following raw materials are used in parts by weight to prepare a packaging film: 8 parts of essential oil, 20 parts of polyvinyl alcohol with a molecular weight within the range of 20,000, 13 parts of polycaprolactone, 10 parts of metallocene polyethylene resin, corn 7 parts of cross-linked starch, 7 parts of carboxymethyl starch, 7 parts of biomass micropowder, 5 parts of Atractylodes macrocephala extract, 4 parts of tourmaline powder, 3 parts of sodium carboxymethyl cellulose, 4 parts of anti-blocking agent, 4 parts of anti-fog additive 3 parts, 3 parts of epoxidized vegetable oil, 3 parts of butyl octyl phthalate, 5 parts of squash gum, 2 parts of paraffin wax, 3 parts of carrageenan.

Embodiment 2

[0026] In this example, the following raw materials are used in parts by weight to prepare a packaging film: 10 parts of essential oil, 23 parts of polyvinyl alcohol with a molecular weight within the range of 20,000, 15 parts of polycaprolactone, 12 parts of metallocene polyethylene resin, corn 10 parts of cross-linked starch, 8 parts of carboxymethyl starch, 9 parts of biomass micropowder, 8 parts of Atractylodes macrocephala extract, 6 parts of tourmaline powder, 4 parts of sodium carboxymethyl cellulose, 6 parts of anti-blocking agent, 6 parts of anti-fog additive 4 parts of epoxidized vegetable oil, 4 parts of butyl octyl phthalate, 6 parts of squash gum, 3 parts of paraffin wax, and 5 parts of carrageenan.

Embodiment 3

[0028] In this example, the following raw materials are used in parts by weight to prepare a packaging film: 12 parts of essential oil, 25 parts of polyvinyl alcohol with a molecular weight within the range of 20,000, 17 parts of polycaprolactone, 13 parts of metallocene polyethylene resin, corn 12 parts of cross-linked starch, 9 parts of carboxymethyl starch, 11 parts of biomass micropowder, 10 parts of Atractylodes macrocephala extract, 7 parts of tourmaline powder, 5 parts of sodium carboxymethyl cellulose, 8 parts of anti-blocking agent, 7 parts of anti-fog additive 5 parts, 5 parts of epoxidized vegetable oil, 5 parts of butyl octyl phthalate, 8 parts of squash gum, 4 parts of paraffin wax, and 6 parts of carrageenan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com