Construction and application of heat-resistant yeast engineering strains for l-lactic acid production

A technology of yeast engineering and strains, applied to the biological field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

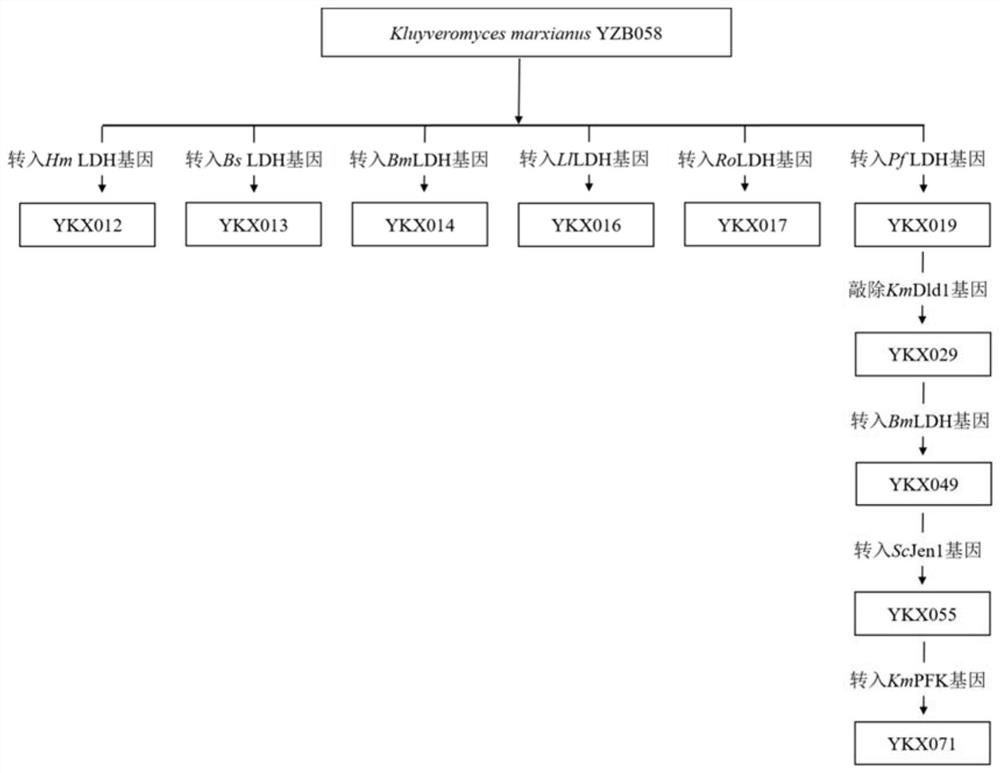

[0054] Embodiment 1. Preparation of bacterial strains:

[0055] 1. the construction of various plasmid vectors among the present invention:

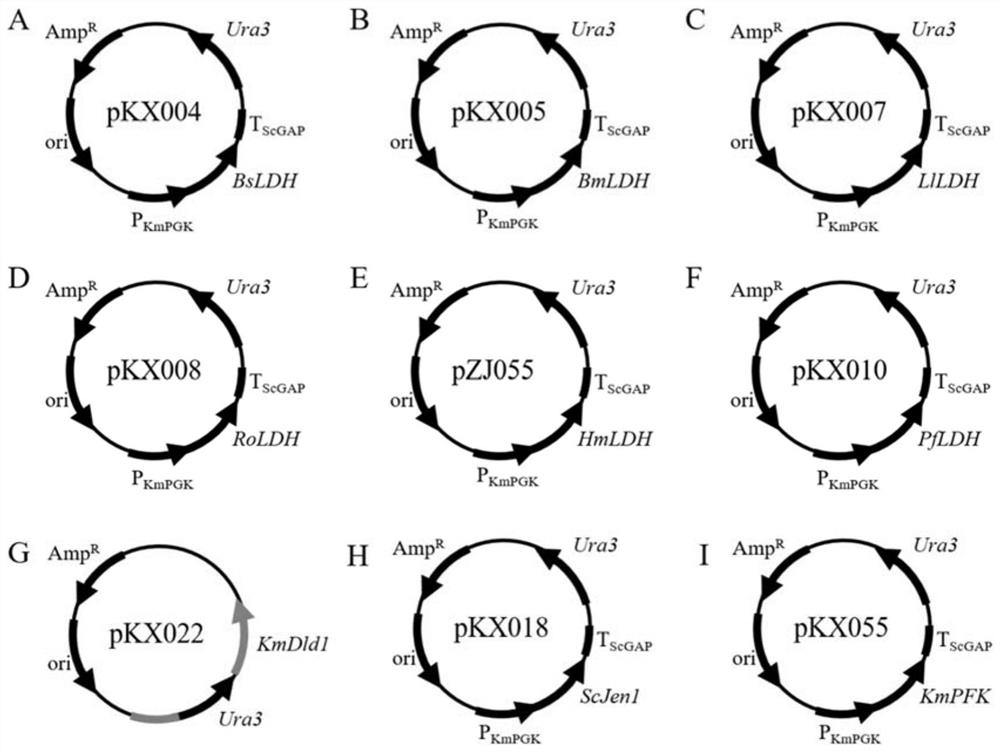

[0056] 1) Construction of gene expression plasmids pKX004, pKX005, pKX007, pKX008 of L-lactate dehydrogenase derived from Bacillus subtilis, Bacillus megaterium, Lactococcus lactis, and Rhizopus oryzae

[0057] BsLDH, BmLDH, L1LDH, and RoLDH were amplified from the genomes of Bacillus subtilis, Bacillus megaterium, Lactococcus lactis, and Rhizopus oryzae. Inserted into the EcoR I and Not I sites of the pZJ042 vector respectively, constructing plasmids pKX004, pKX005, pKX007, pKX008 ( figure 2 ).

[0058] The specific operation steps are as follows:

[0059] (1) With the genomes of the above-mentioned various bacteria as templates, the primer pair BsLDH--EcoRI-F (SEQ ID No.1) and BsLDH-NotI-R (SEQ ID No.2), BmLDH-EcoRI-F (SEQ ID No.2) ID No.3) and BmLDH-NotI-R (SEQ IDNo.4), LlLDH-EcoRI-F (SEQ ID No.5) and LlLDH-NotI-R (SEQ ID No.6), ...

Embodiment 2

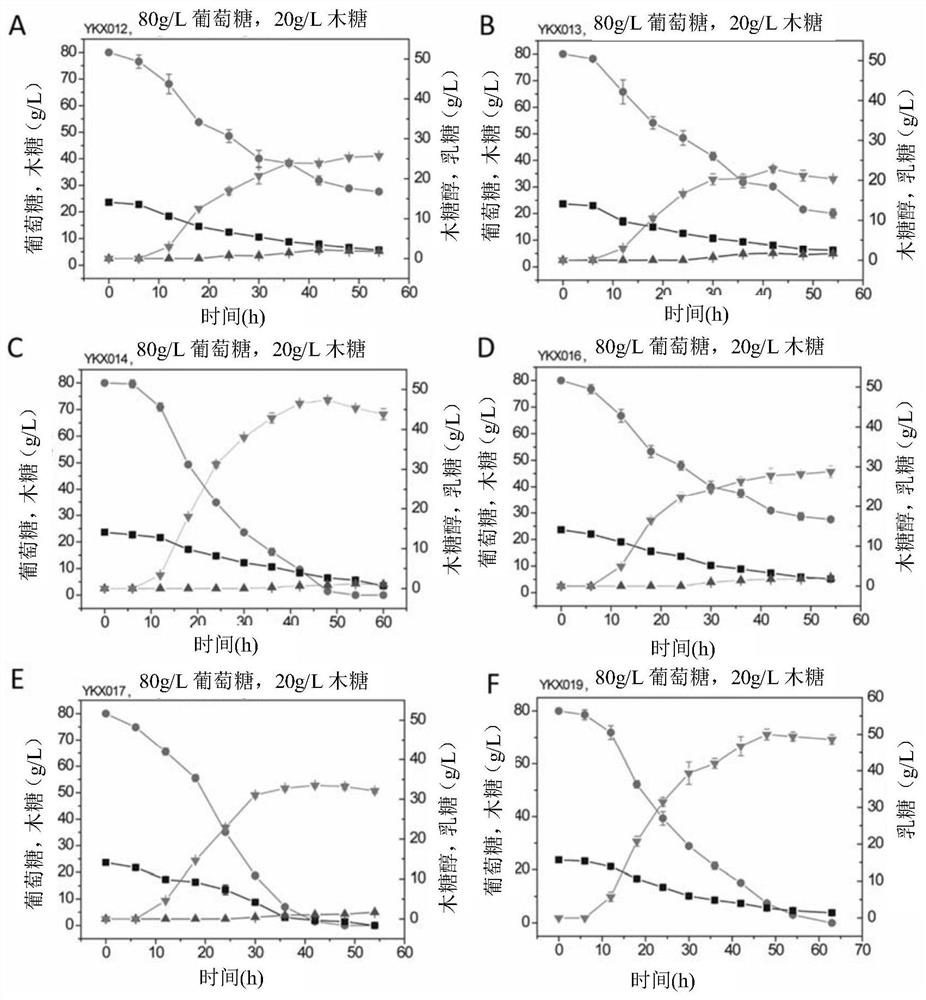

[0157]Embodiment 2. The situation that engineering strains containing different genes are fermented at high temperature

[0158] This example is used to compare the effects of co-utilizing glucose and xylose to produce L-lactic acid with strains containing different genes constructed in the present invention. The results showed that among all the engineering genes, strain YKX071 had the best effect of co-utilizing glucose and xylose to produce L-lactic acid.

[0159] 1. Resuscitate all frozen strains on YPD solid medium plates: YKX013, YKX014, YKX016, YKX017, YKX012, YKX019, YKX029, YKX049, YKX055, YKX071. Incubate at 37°C for 24 hours.

[0160] 2. Single clones were picked and inoculated in 5ml YPD liquid medium. Incubate overnight at 37°C on a shaker at 250rpm.

[0161] 3. Configure 30 bottles of 30ml YPDX liquid medium in 250ml Erlenmeyer flasks. YPDX formula: 10g / L yeast extract, 20g / L bacto-peptone, 80g / L glucose, 20g / L xylose. Sterilized and ready to use.

[0162] 4...

Embodiment 3

[0165] Embodiment 3.YKX071 bacterial strain is to the utilization situation of corncob

[0166] This example is used to verify whether the final strain YKX071 can ferment and produce L-lactic acid with the corncob residue after alkali treatment as the sole carbon source.

[0167] 1. Resuscitate the frozen strain YKX071 on the YPD solid medium plate, and culture it upside down in a 37°C incubator for 24 hours.

[0168] 2. Pick a single clone and inoculate it in 50ml YPD liquid medium. Incubate overnight at 37°C on a shaker at 250rpm.

[0169] 3. Prepare 500ml of fermentation medium and put it in a 1L fermentation tank. Formula: 10g / L yeast extract, 20g / L bacto-peptone, 180g / L alkali-treated corn cob residue. Sterilized and ready to use.

[0170] 4. Transplant the strain into 500ml fermentation medium, make the initial OD600 1, add cellulase at the ratio of 15FPU / g corncob residue, and ferment at 42°C, 250rpm, and 0.5vvm oxygen flow.

[0171] 5. Take samples at intervals, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com