Automatic cleaning mechanism for silk woven cloth

An automatic cleaning and cloth technology, applied in the field of silk fabric processing, can solve the problems of unable to remove oil stains on silk fabrics, unsatisfactory decontamination effect, and reduce the quality of silk fabrics, so as to achieve good cleaning and decontamination effects and avoid repeated use , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0022] Example.

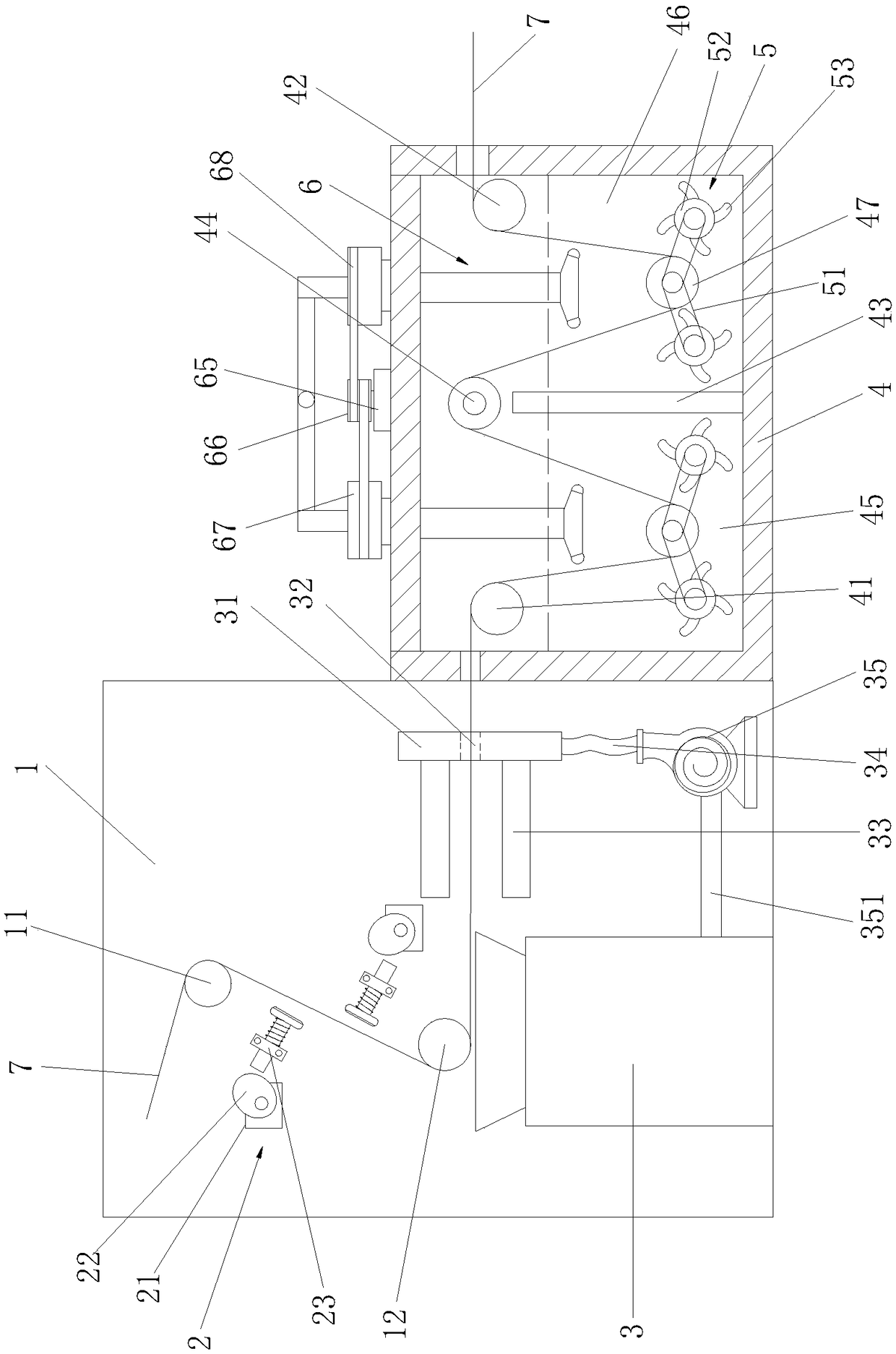

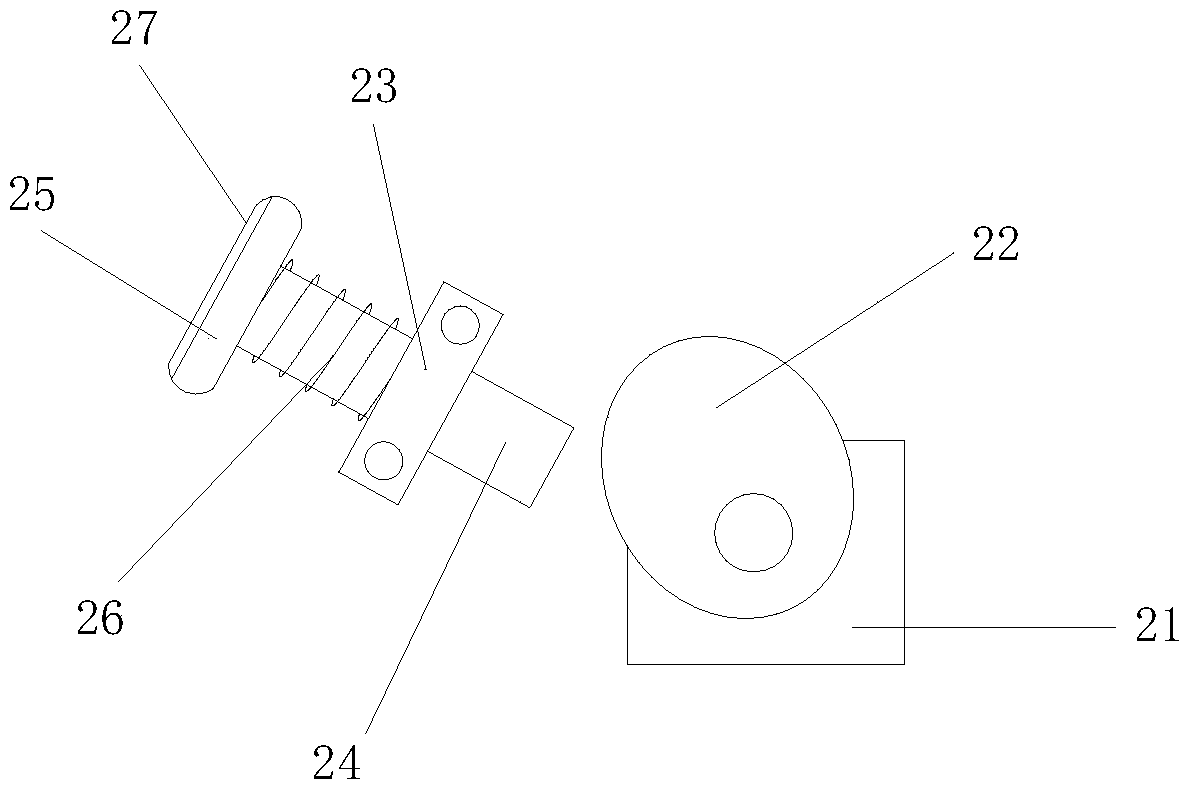

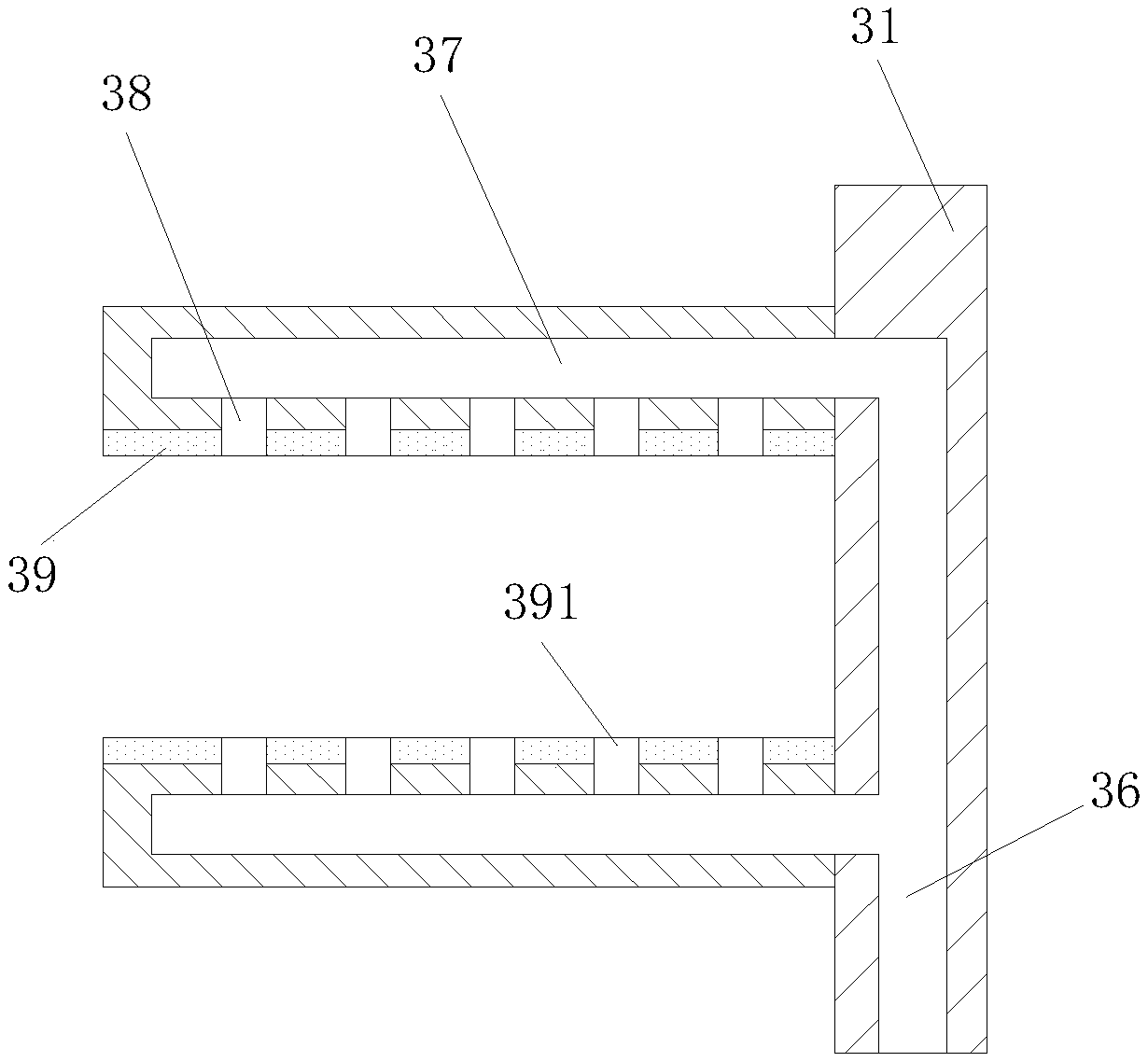

[0023] Such as Figure 1-5 As shown, a kind of automatic cleaning mechanism of silk weaving cloth, comprises working frame 1, and described working frame 1 is provided with the first guide roller 11 and the second guide roller 12 that add up and down wrongly distributed, the first guide roller 11 and the second guide roller 12 Between the second guide rollers 12, a pair of shocking cloth devices 2 that are staggered up and down and center-symmetrical are arranged, and a slag collection box 3 is provided below the shock cloth device 2; a cleaning box 4 is provided on one side of the work frame 1 for cleaning. The left and right sides of box 4 are respectively provided with the 3rd guide roller 41 and the 4th guide roller 42, between the second guide roller 12 and the 3rd guide roller 41, be provided with dust-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com