Non-ampholyte free-flow isoelectric focusing electrophoretic separation method

An isoelectric focusing electrophoresis and ampholyte technology, which is applied in the direction of material analysis, material analysis, and measurement device by electromagnetic means, which can solve the problems of affecting the sensitivity of ultraviolet detection and expensive ampholyte solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

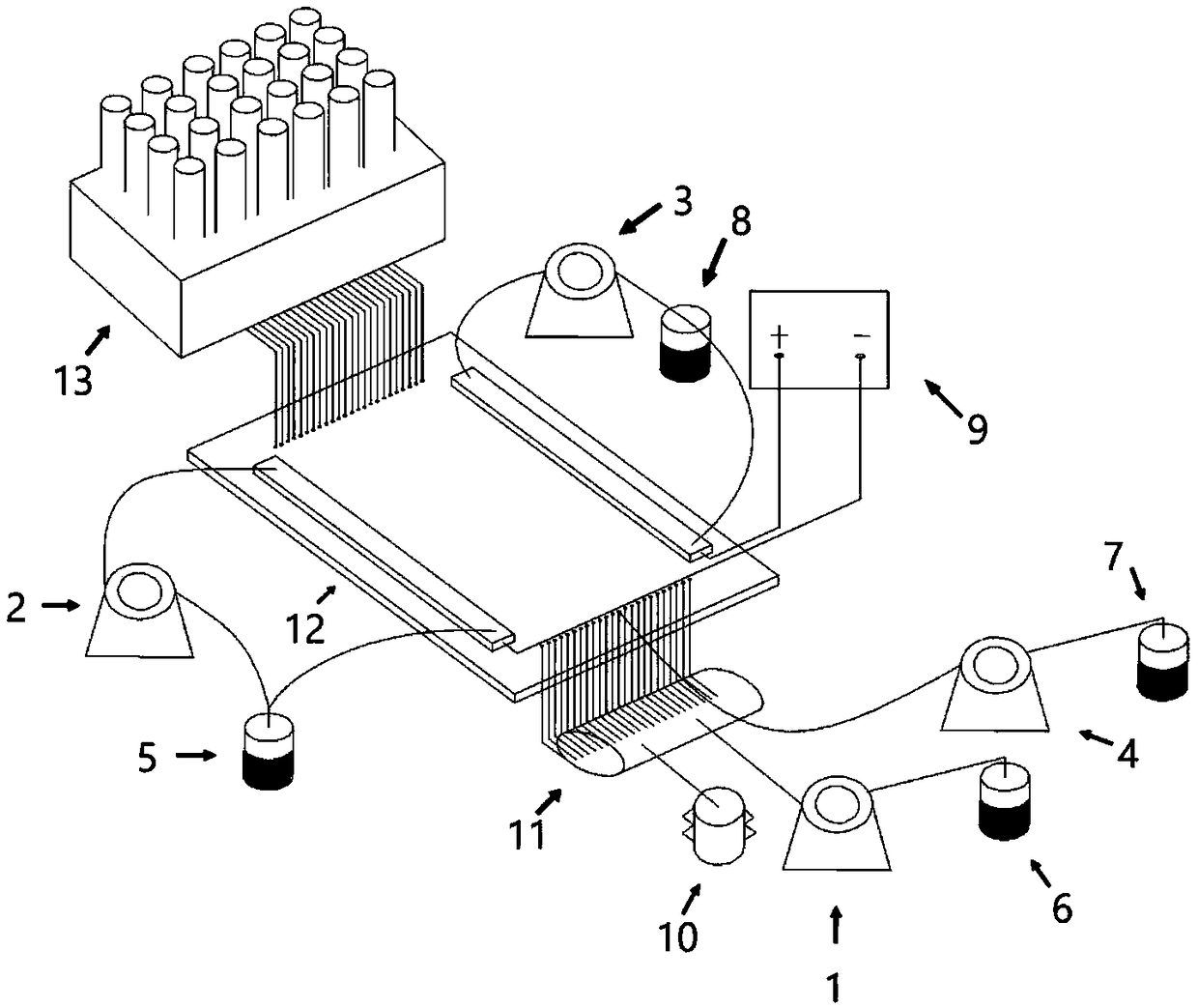

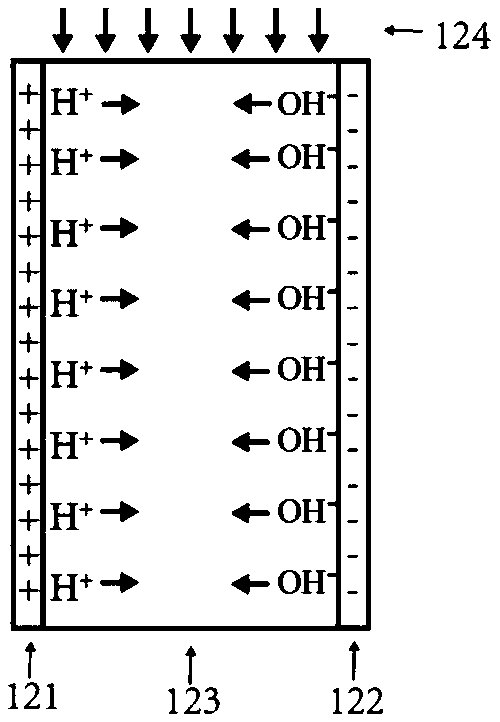

[0029] see figure 1 Shown is a schematic diagram of the free-flow electrophoresis device used in this application. The device includes: an operating mobile phase driving pump (1) used to drive the operating mobile phase in the operating mobile phase liquid storage bottle (6) into the gas-liquid buffer device (11). Use the air cylinder (10) in the gas-liquid buffer device (11) to remove the air bubbles in the mobile phase, so that the mobile phase is filled with the free flow electrophoresis cavity (12); the negative electrode liquid circulation pump (2) is used to drive the negative electrode The negative electrode liquid circulation in the liquid storage tank (5), the positive electrode liquid circulation pump (3) is used to drive the positive electrode liquid circulation in the positive electrode liquid storage tank (8); a sample pump (4) is used for The sample in the sample solution storage bottle (7) is pumped into the free-flow electrophoresis chamber (12); a high-voltag...

Embodiment 2

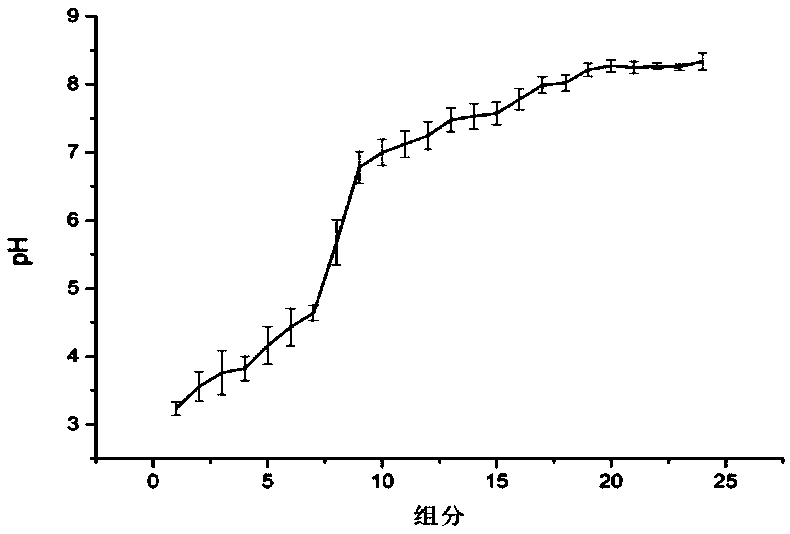

[0033]The first step is to turn on the operating mobile phase to drive the pump (1) to pump the operating mobile phase in the operating mobile phase liquid storage bottle (6) into the gas-liquid buffer device (11). Use the gas cylinder (10) in the gas-liquid buffer device (11) to remove the air bubbles in the running mobile phase, make the running mobile phase fill the free-flow electrophoresis cavity (12) and control the flow rate at 1ml / min. Turn on the negative electrode liquid circulation pump (2) and the positive electrode liquid circulation pump (3) to pump the positive and negative electrode liquids in the negative electrode liquid storage tank (5) and the positive electrode liquid storage tank (8) into the free flow electrophoresis chamber In the positive and negative electrode chambers, and maintain the circulation of the electrode solution. Turn on the high voltage power supply (9) and adjust to 400V voltage. Keep the device running stably for 30 minutes to make it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com