A staggered grid slow wave structure with sinusoidal function profile

A slow-wave structure and sine function technology, applied in the field of slow-wave structures, can solve the problems of low average coupling impedance and weak injection-wave interaction of slow-wave structures, so as to improve electron interaction efficiency and output power, increase electric field strength, Improve the effect of weak injection wave interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In this embodiment, the sinusoidal function profile interlaced grating slow wave structure working in the G frequency band is taken as an example.

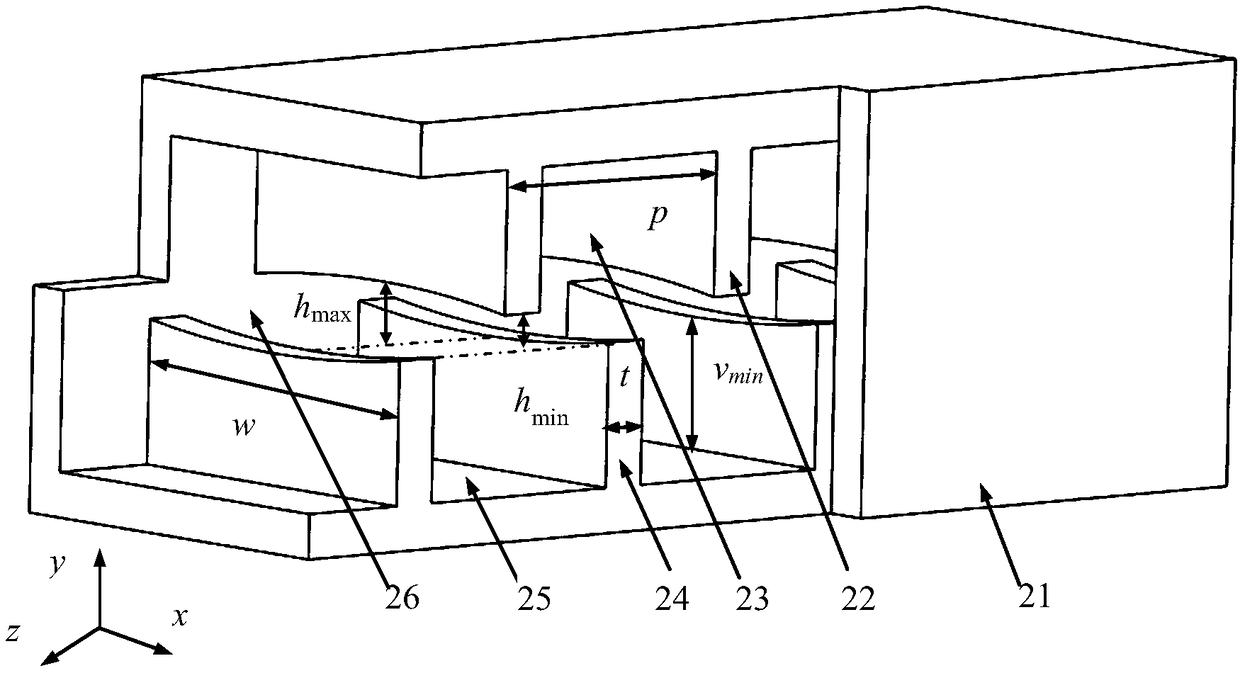

[0031] like figure 2 As shown, the staggered grid slow wave structure with sinusoidal function profile of the present invention includes a cuboid housing 21 , upper grid teeth 22 , lower cavity 23 , lower grid teeth 24 , lower cavity 25 and belt-shaped electron injection channel 26 . The structural parameters of the slow wave structure are: p=0.6mm, v min =0.29mm, w=0.84mm, t=0.1mm, h max = 0.14 mm and h min = 0.08 mm. The contours of the upper grid teeth 22 and the lower grid teeth 24 in the widthwise direction are all subject to a sine function distribution. Taking the midpoint of the left narrow side of the electron injection channel as the origin, the function corresponding to the upper grid tooth 22 is y=0.04+0.03*sin(2π / 1.68*x) (0≤x≤0.84), and the function corresponding to the lower grid tooth 24 The function is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com