Method for separating and purifying hydrogen gas from dry gas of refining gas tank

A refining and chemical gas separation technology, applied in separation methods, chemical instruments and methods, dispersion particle separation, etc., can solve problems such as waste of resources, environment, pollution, etc., and achieve significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

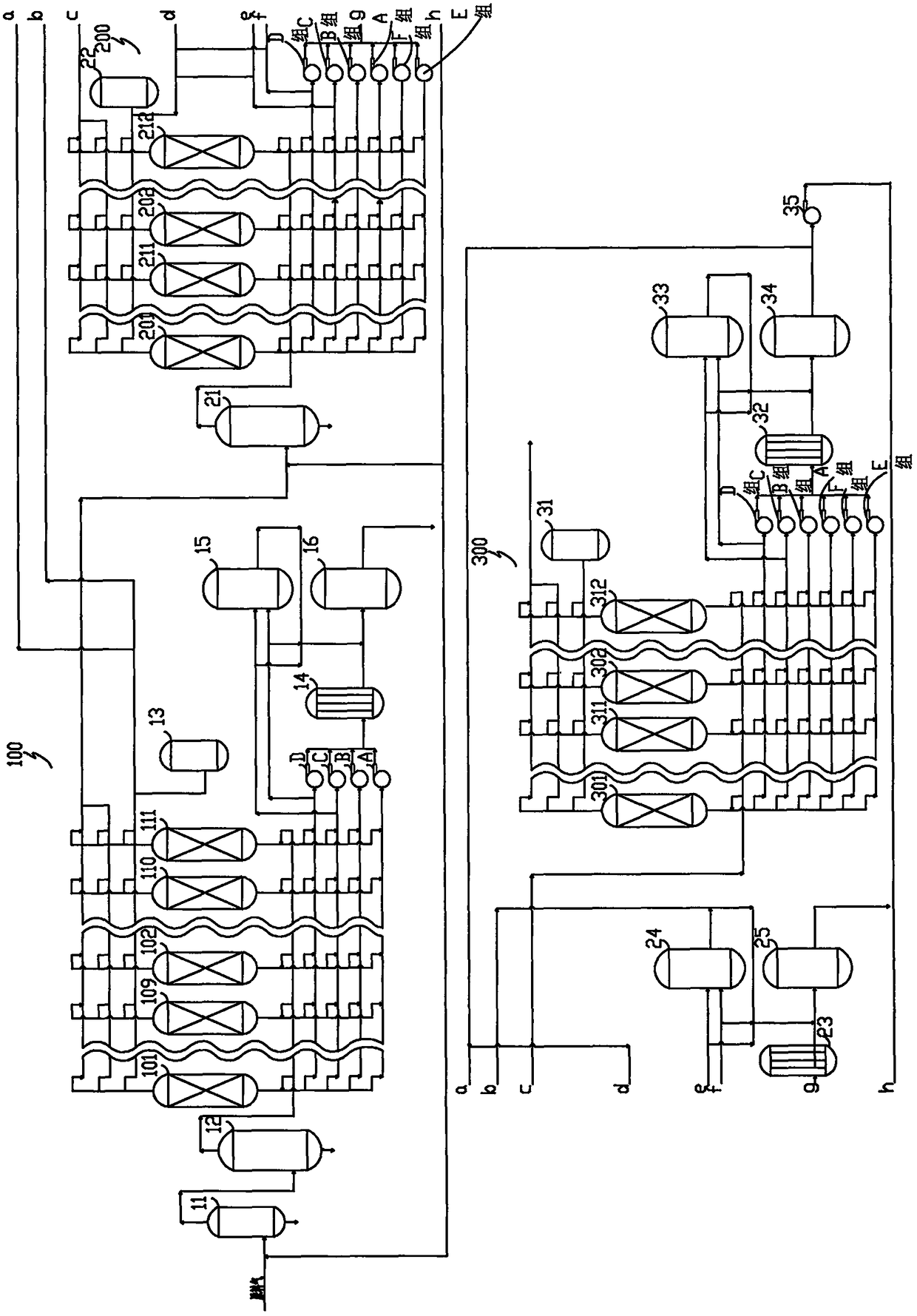

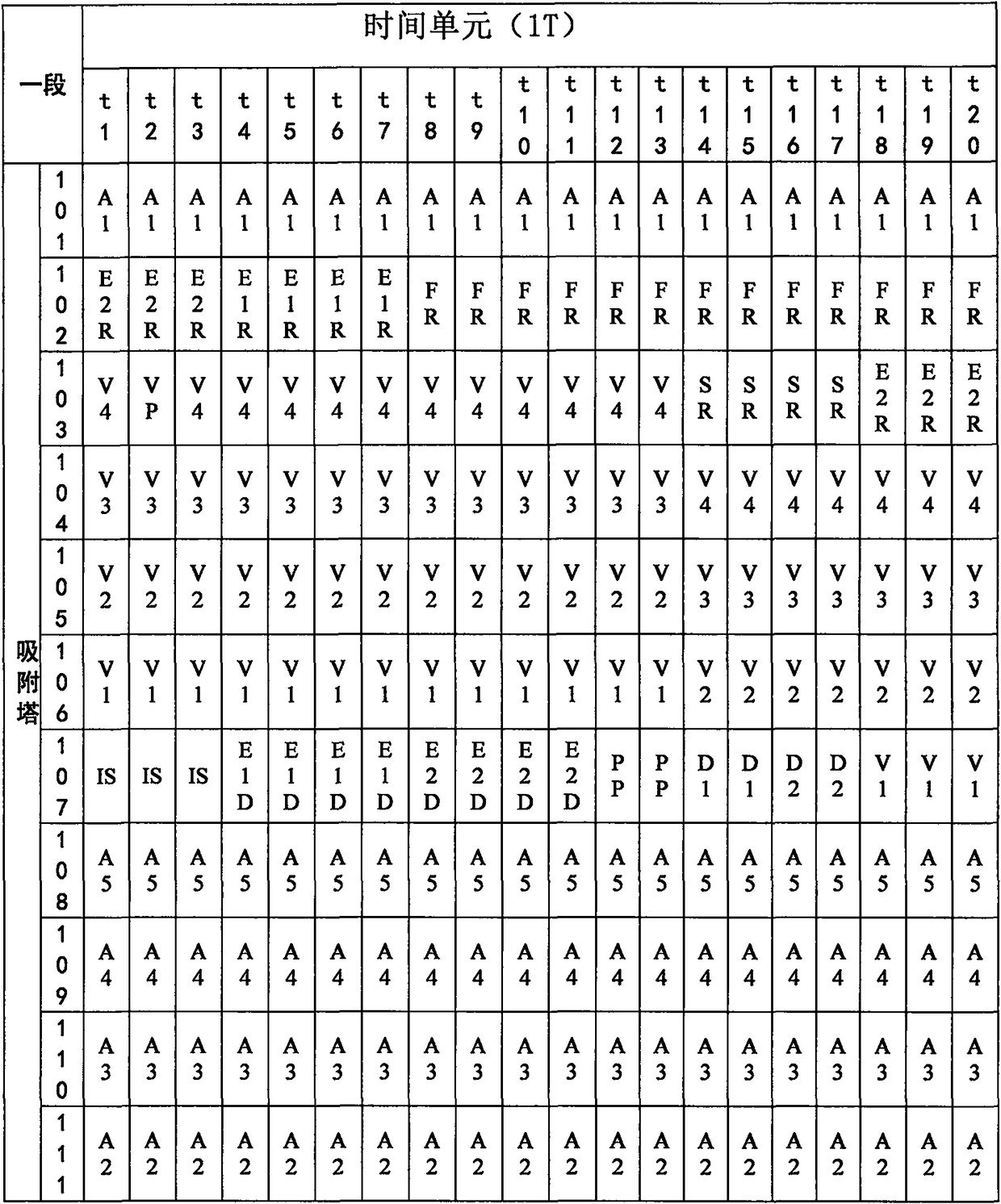

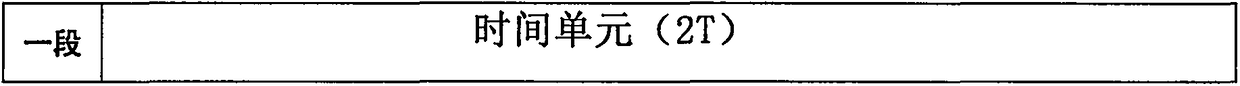

[0019] The specific implementation of the method for separating and purifying hydrogen from the dry gas of the refinery gas cabinet of the present invention will be described in detail below with reference to the accompanying drawings. The characteristics and advantages of the method for separating and purifying hydrogen from the dry gas of the refinery gas cabinet of the present invention will become more obvious.

[0020] The raw gas is the recovered dry gas from the refinery gas cabinet:

[0021] Component

H 2

CH 4

C2

C3

C4

C5+

N 2

CO

CO 2

∑

Content (V%)

40

15

13.5

7.8

3.30

4.10

14.5

0.21

1.0

99.4

[0022] The raw material gas contains 0.60 (V%) hydrogen sulfide, which is less than 20 ppm after desulfurization.

[0023] Pressure: about 0.42MPa.

[0024] Temperature: ≤40°C.

[0025] See attached figure 1 , the method for separating and purifying hydrogen from the dry gas of the refi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com