Stabilizing and curing processing system and processing system for fly ash by waste incineration

A waste incineration fly ash and treatment system technology, applied in the field of waste incineration fly ash stabilization and solidification treatment system, can solve the problems of no function model establishment, no automatic control, no consideration, etc., so as to improve the treatment effect and reduce the treatment cost. The effect of cost and efficient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

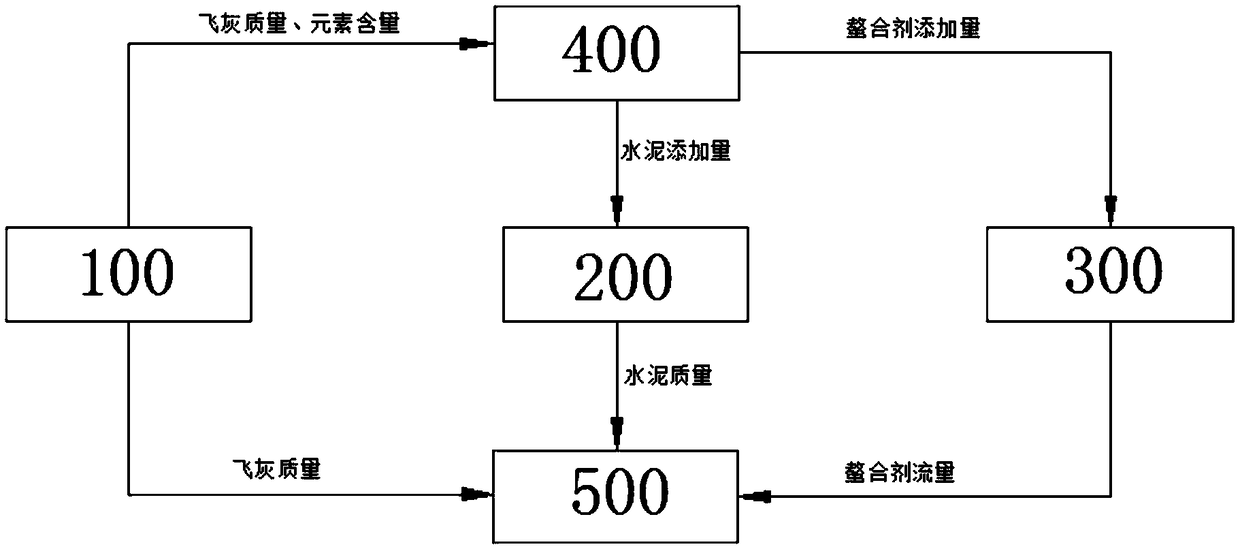

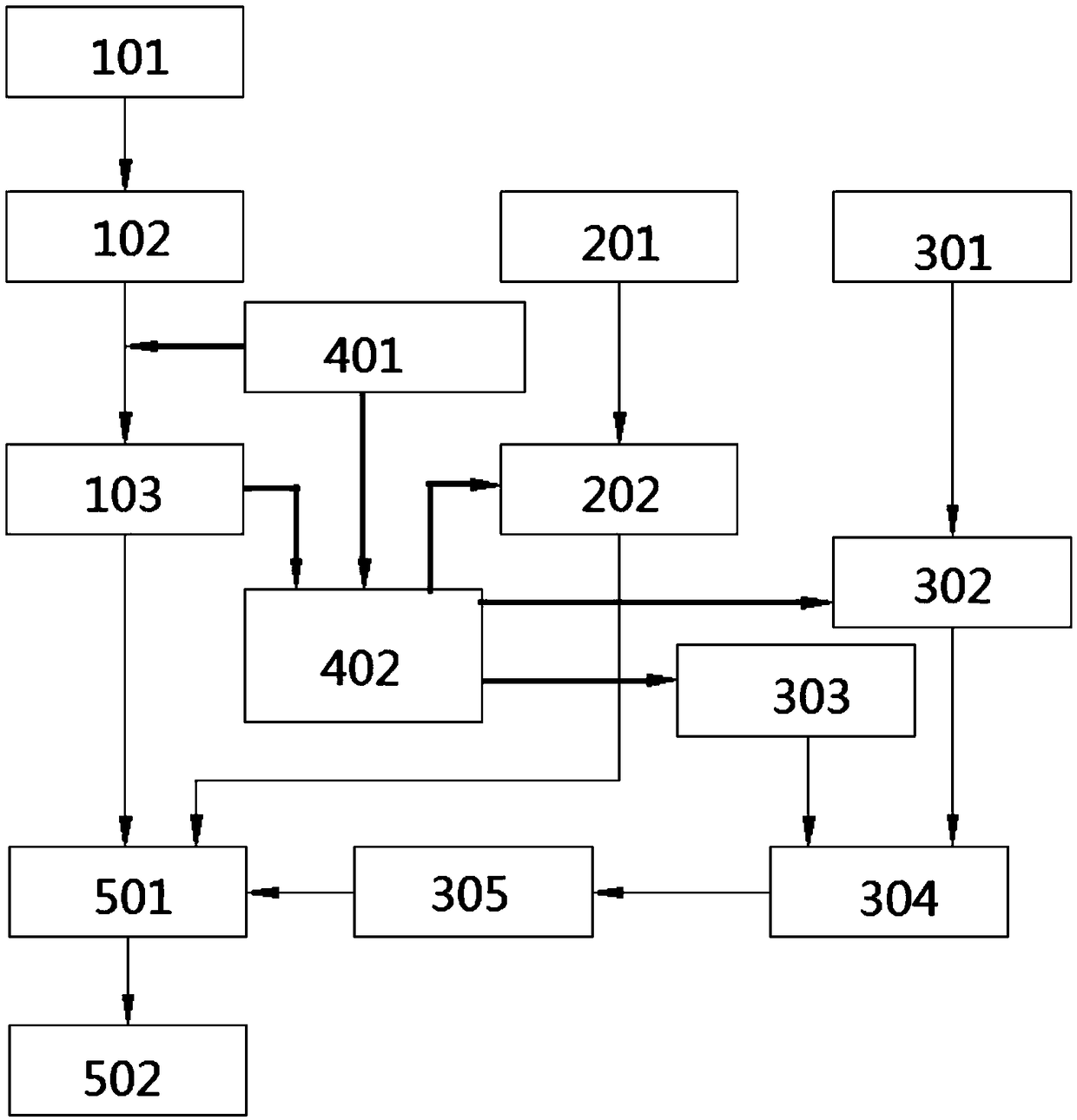

[0038] A stabilized and solidified treatment system for waste incineration fly ash, comprising a fly ash metering unit 100, a cement metering unit 200, a chelating agent metering unit 300, a detection and addition control unit 400, and a stabilization unit 500, the fly ash metering unit 100, The cement metering unit 200 and the chelating agent metering unit 300 are all communicated with the stabilizing unit 500;

[0039] The detection adding control unit 400 includes

[0040] The online detection module 401 is used to detect the content of each heavy metal element in the waste incineration fly ash in the fly ash metering unit; and

[0041] The control module (402) adopts Siemens S7-300PLC control cabinet, which is used to receive and process the data signals from the online detection module and the fly ash metering unit, and then control the cement metering unit and the chelating agent metering unit to stabilize The unit is dosed according to the target addition amount.

[0...

Embodiment 2

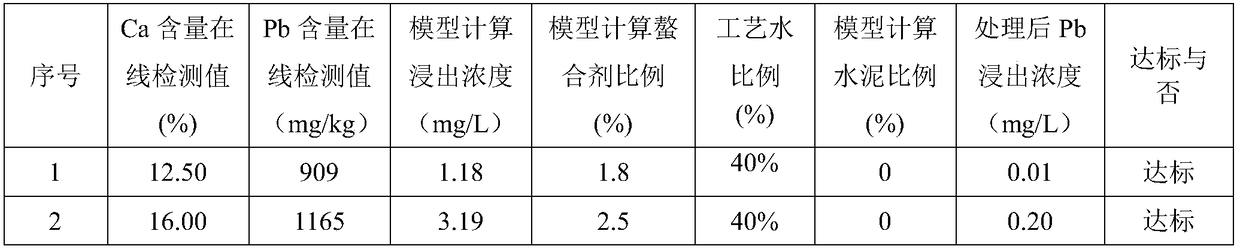

[0050] The fly ash of a waste-to-energy plant in Shanghai is treated by the waste incineration fly ash stabilization and solidification precise and efficient treatment system of the present invention. The fly ash metering unit 100 controls the amount of fly ash processed in each batch to be 1000kg, and the fly ash enters the stabilizing and solidifying mixing system through the screw feeder to ensure the uniformity of the fly ash. The online detection device is installed between the feeder and the metering bin.

[0051]The contents of calcium, lead and cadmium in the first batch of fly ash were 10.8%, 2191mg / kg, 260mg / kg and other heavy metal content data were detected by laser-induced plasma spectrometer (LIBS). The calcium content data is automatically input into the cement addition ratio calculation control module of the detection and addition control unit 400. Since the calcium content is lower than 12%, according to the model P c =2×(12-C Ca )%, the amount of cement add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com