Building mortar and preparation process thereof

A mortar and construction technology, applied in the field of construction mortar and its preparation process, can solve the problems of difficult distribution of mortar, lower mechanical properties of mortar, stress concentration, etc., achieve good sound insulation effect, good adhesion, and increase strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

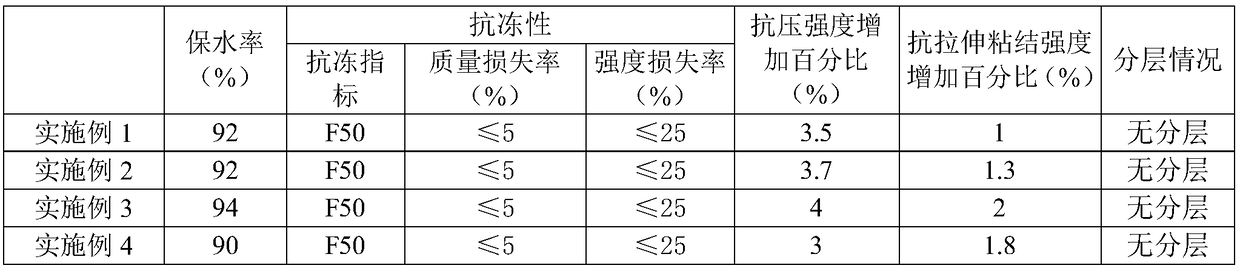

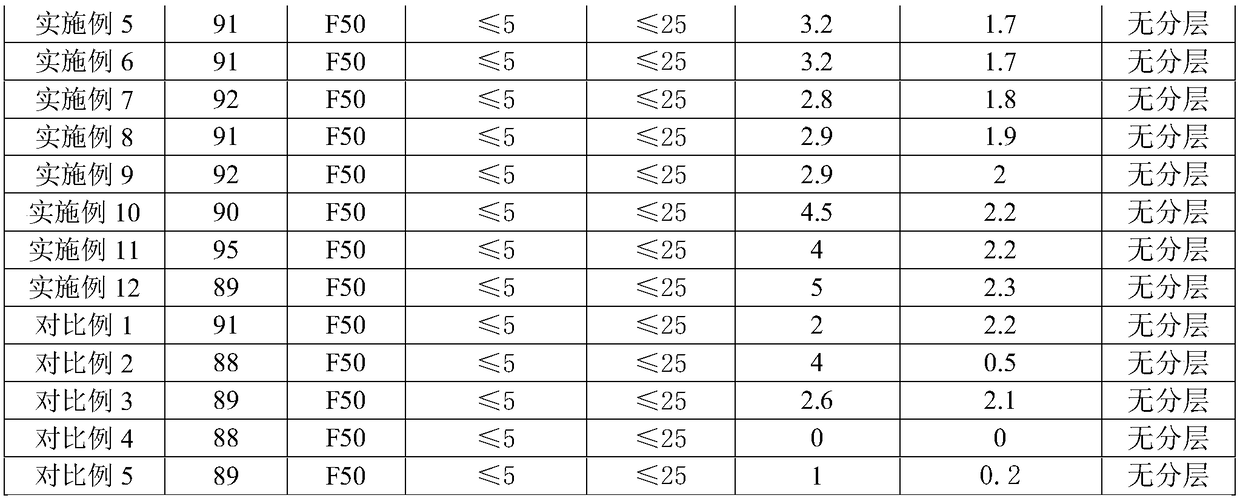

Examples

Embodiment 11

[0081] A kind of construction mortar, the difference between embodiment 11 and embodiment 3 is that the ceramic particles and glass particles are nanoparticles.

Embodiment 12

[0083] A construction mortar, the difference between embodiment 12 and embodiment 11 is that a layer of titanium carbide film is deposited on the surface of ceramic particles.

[0084] A kind of construction mortar preparation technology, comprises the following steps:

[0085] Step 1, take by weighing each above-mentioned component, for subsequent use;

[0086] Step 2. Soak ceramic particles and glass particles in inorganic strong alkali for 1-3 days, take out and drain after soaking;

[0087] Step 3, grinding the ceramic particles and glass particles drained in step 2;

[0088] Step 4. Mix the sand, cement and water evenly, then add the ceramic particles, glass particles, and gypsum in step 3 in sequence, stir evenly, and finally add the adhesive and mix evenly.

[0089] The ceramic particles in the step 1 are obtained by crushing and grinding ceramic brick waste; the glass particles are obtained by crushing and grinding the glass at the sieving place in the construction w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com