Method for preparing sialoglycopeptide from tuna eggs

A technology of sialic acid sugar and tuna, which is applied in the field of food processing to achieve the effect of high extraction rate and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

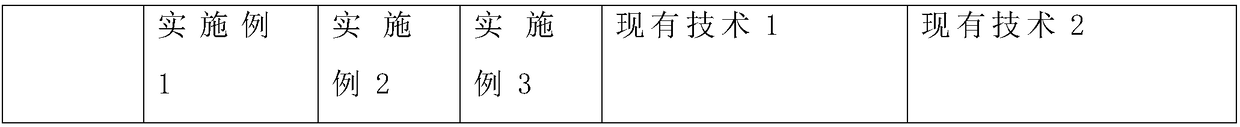

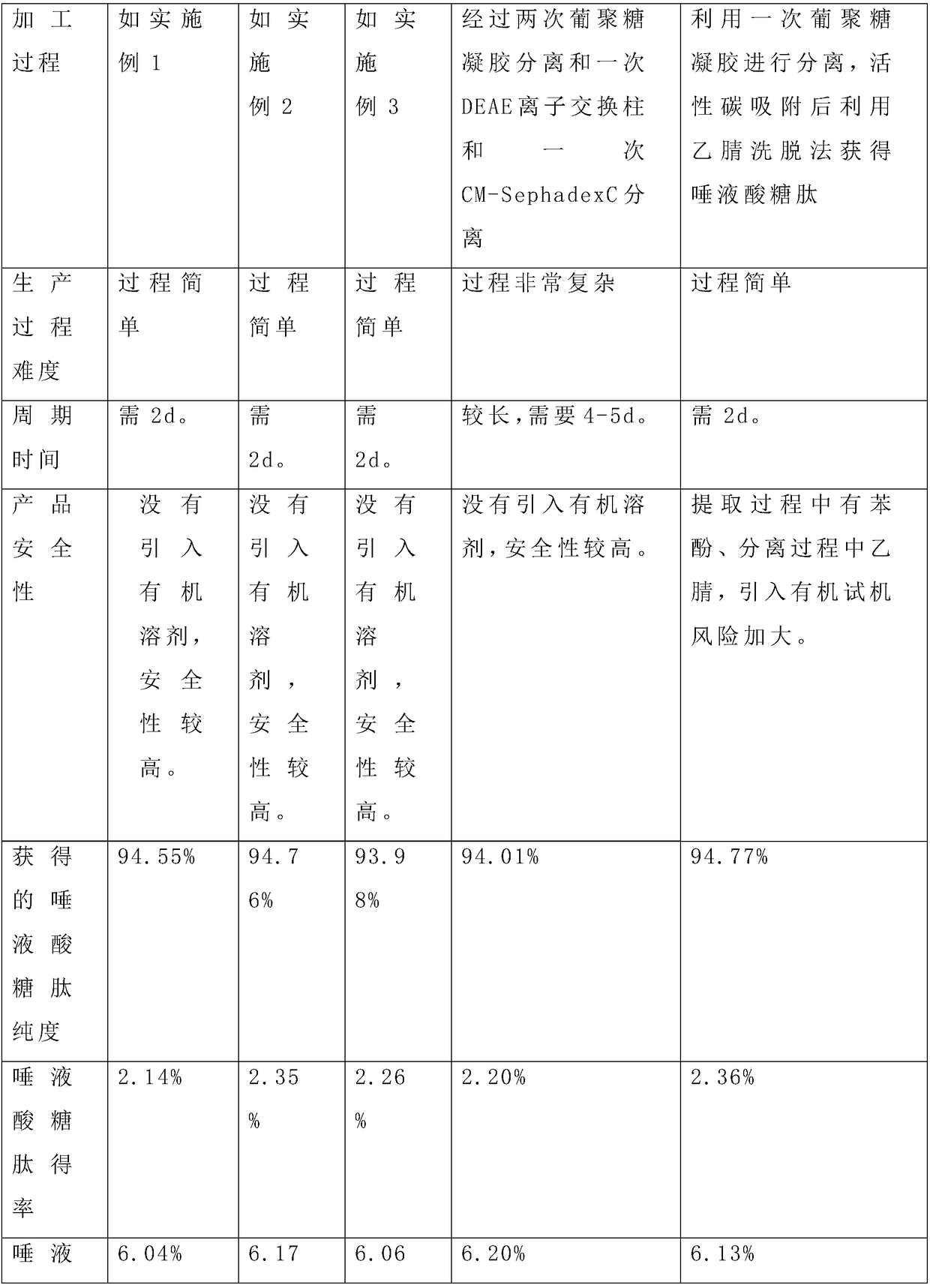

Examples

Embodiment 1

[0043] This implementation case shows a method for preparing sialic acid glycopeptide from tuna roe according to the following steps:

[0044]The frozen tuna roe was taken out and thawed at 4°C, homogenized by a homogenizer, frozen at -20°C for 12 hours, and freeze-dried by a freeze dryer to obtain tuna roe powder. Add 10 times the volume of absolute ethanol (1 / 10, w / v) to the freeze-dried fish egg powder and stir for 10 h to degrease, during which the absolute ethanol is replaced every 3 h. After degreasing, ethanol is removed by double-layer fat filtration, and the filter residue is air-dried in a cold air dryer for 6 hours to obtain defatted tuna roe powder. Take defatted fish egg powder and add deionized water to extract sialic acid glycopeptide (1 / 20, w / v) according to 20 times of its weight to volume ratio. The extraction temperature is 4° C., and the extraction time is 12 hours. During the period, ultrasonic treatment was performed every hour to assist in the extractio...

Embodiment 2

[0046] This implementation case shows a method for preparing sialic acid glycopeptides from tuna eggs according to the following steps: take out the frozen tuna eggs and thaw them at 4°C, homogenize them with a homogenizer, and freeze them at -20°C for 12 hours. The tuna roe powder is obtained by freeze-drying with a freeze dryer. Add 13 times the volume of absolute ethanol (1 / 12, w / v) to the freeze-dried fish egg powder and stir for 10 h to degrease, during which the absolute ethanol is replaced every 3 h. After degreasing, ethanol was removed by double-layer fat filtration, and the filter residue was air-dried in a cold air dryer for 8 hours to obtain defatted tuna roe powder. Take defatted fish egg powder and add deionized water according to its weight-to-volume ratio 25 times to extract sialic acid glycopeptide (1 / 25, w / v). The extraction temperature is 8° C. and the extraction time is 14 hours. During the period, ultrasonic treatment was performed every hour to assist in...

Embodiment 3

[0048] This implementation case shows a method for preparing sialic acid glycopeptide from tuna roe according to the following steps:

[0049] The frozen tuna roe was taken out and thawed at 4°C, homogenized by a homogenizer, frozen at -20°C for 12 hours, and freeze-dried by a freeze dryer to obtain tuna roe powder. Add 15 times the volume of absolute ethanol (1 / 15, w / v) to the freeze-dried fish egg powder and stir for 10 h to degrease, during which the absolute ethanol is replaced every 3 h. After degreasing, ethanol is removed by double-layer fat filtration, and the filter residue is air-dried in a cold air drier for 10 hours to obtain defatted tuna roe powder. Take defatted fish egg powder and add deionized water according to 30 times of its weight-to-volume ratio to extract sialic acid glycopeptide (1 / 30, w / v). The extraction temperature is 10° C., and the extraction time is 16 hours. During the period, ultrasonic treatment was performed every hour to assist in the extrac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap