Construction method for laying municipal sewage disposal pipes

A technology for sewage pipes and construction methods, which is applied in the sewer system, waterway system, water supply device, etc., can solve the problems of environmental stress sensitivity, low water absorption, and is not suitable for temperature difference between day and night, and achieves improved mechanical strength and improved integration. The effect of high degree and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

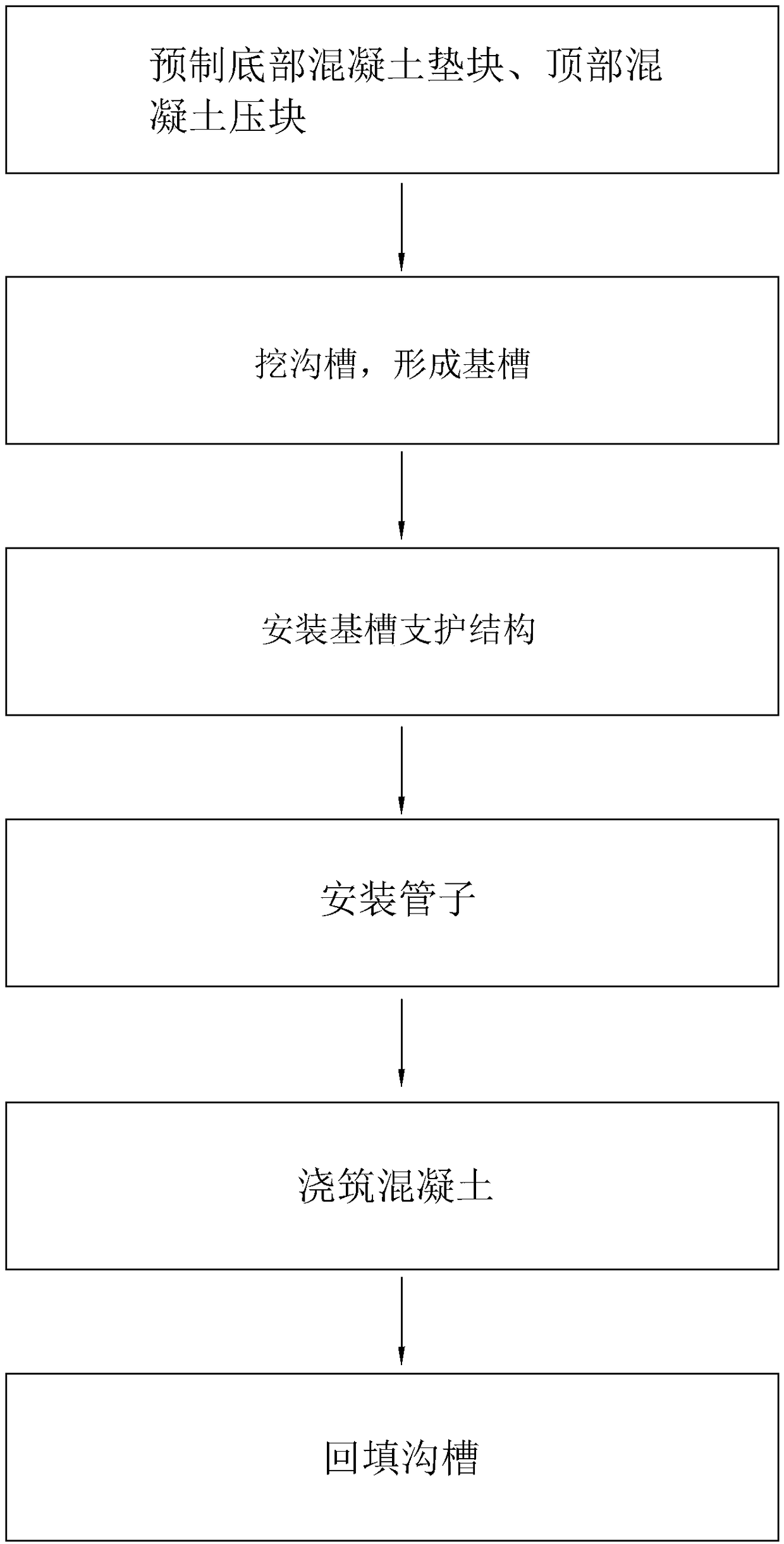

[0054] A construction method for laying municipal sewage pipelines, comprising the following steps:

[0055] Step 1, prefabricating the bottom concrete block and the top concrete compact;

[0056] Step 2, digging a trench to form a foundation trench;

[0057] Step 3, install the foundation groove support structure;

[0058] Step 4, place the prefabricated multiple bottom concrete pads, one or more pipes and the prefabricated multiple top concrete briquettes successively into the foundation trench by means of lifting equipment and manual assistance, one top concrete briquette and A bottom concrete pad forms an up-and-down composite structure, so that the two ends of each pipe are respectively supported in a semicircular groove of a bottom concrete pad, and are respectively compressed in a semicircular concave groove of a top concrete block. In the groove; and directly place the expansion joint plate between the combined structure of the adjacent two sets of bottom concrete pa...

Embodiment 2

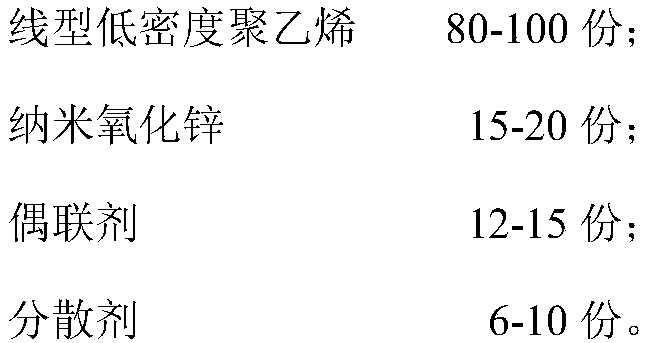

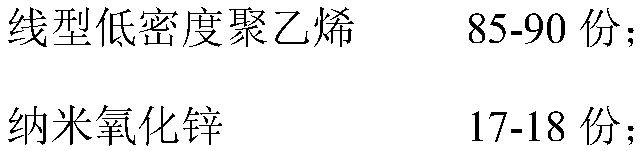

[0064] The difference from Example 1 is that, in terms of parts by weight, the expansion joint plate raw materials are as shown in Table 1.

Embodiment 3

[0066] The difference from Example 1 is that, in terms of parts by weight, the expansion joint plate raw materials are as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com