Detection device and method for simulating furnace wall growth process of aluminum electrolytic bath

A technology of aluminum electrolytic cell and growth process, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., and can solve the problem of not being able to give the microscopic shape of the side of the side during the dynamic process of the side growth process, and not being able to directly obtain the actual situation of the side of the side and the growth status of the side of the side. and the shape of the furnace are difficult to achieve the effects of long life and efficient operation, convenient installation and disassembly, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

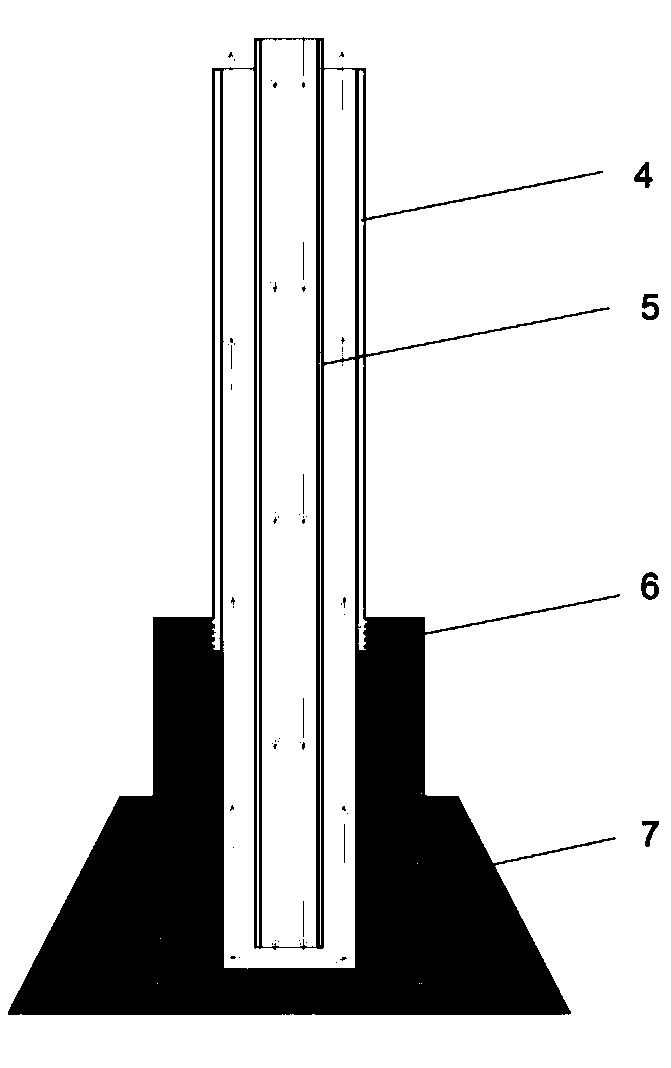

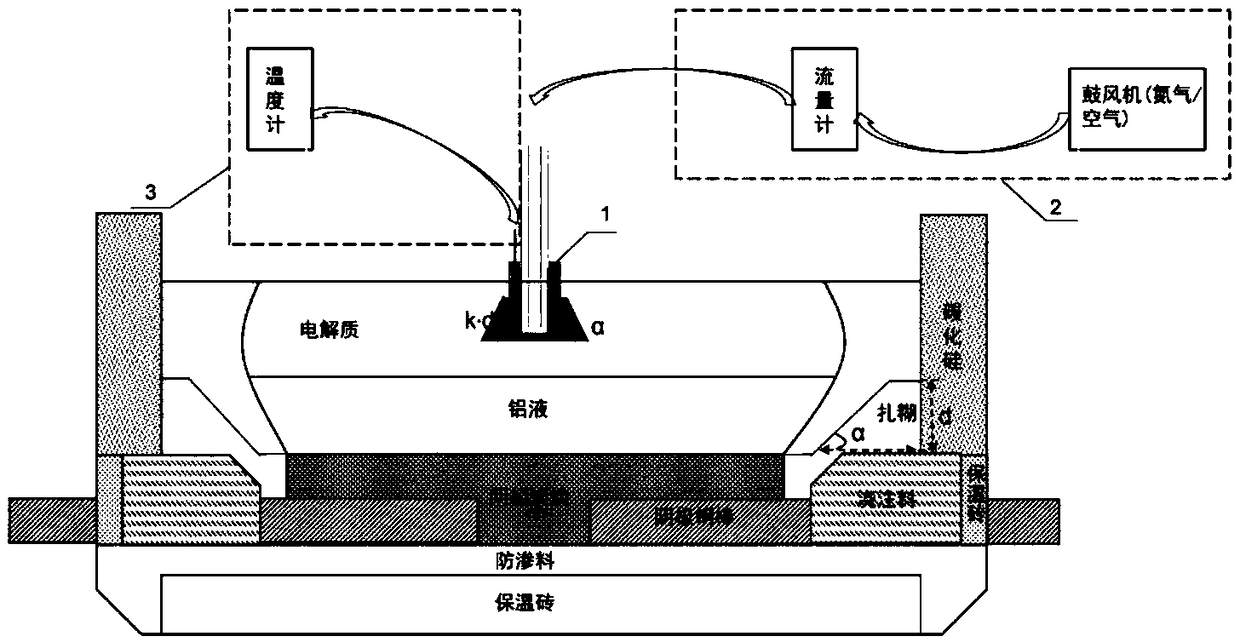

[0031] see Figure 1-Figure 5 , a detection device for simulating the side growth process of an aluminum electrolytic cell, comprising a side growth device 1 , a cooling system 2 and a temperature control system 3 . The side growing device 1 includes a side carbon block model 6 and a side artificial leg extension model 7 . The side carbon block model 6 is a solid cylinder made of the same material as the side carbon block of the actual aluminum electrolytic cell and with a central counterbore, and its side wall thickness is K times the thickness of the actual aluminum electrolytic cell side carbon block. The side artificial extension leg model 7 is a solid revolving body made of the same material as the actual aluminum electrolytic cell side artificial extension leg and with a central through hole. Similar and the similarity ratio is K, the side artificial leg extension model is fixed outside the side carbon block model through the central through hole suit. That is to say, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com