Continuous mode black tea fermentation machine

A technology of a black tea fermentation machine and a fermentation chamber, which is applied in the field of tea fermentation, can solve the problems of large differences in the supply of temperature, humidity and oxygen between the upper and lower layers, uneven fermentation, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

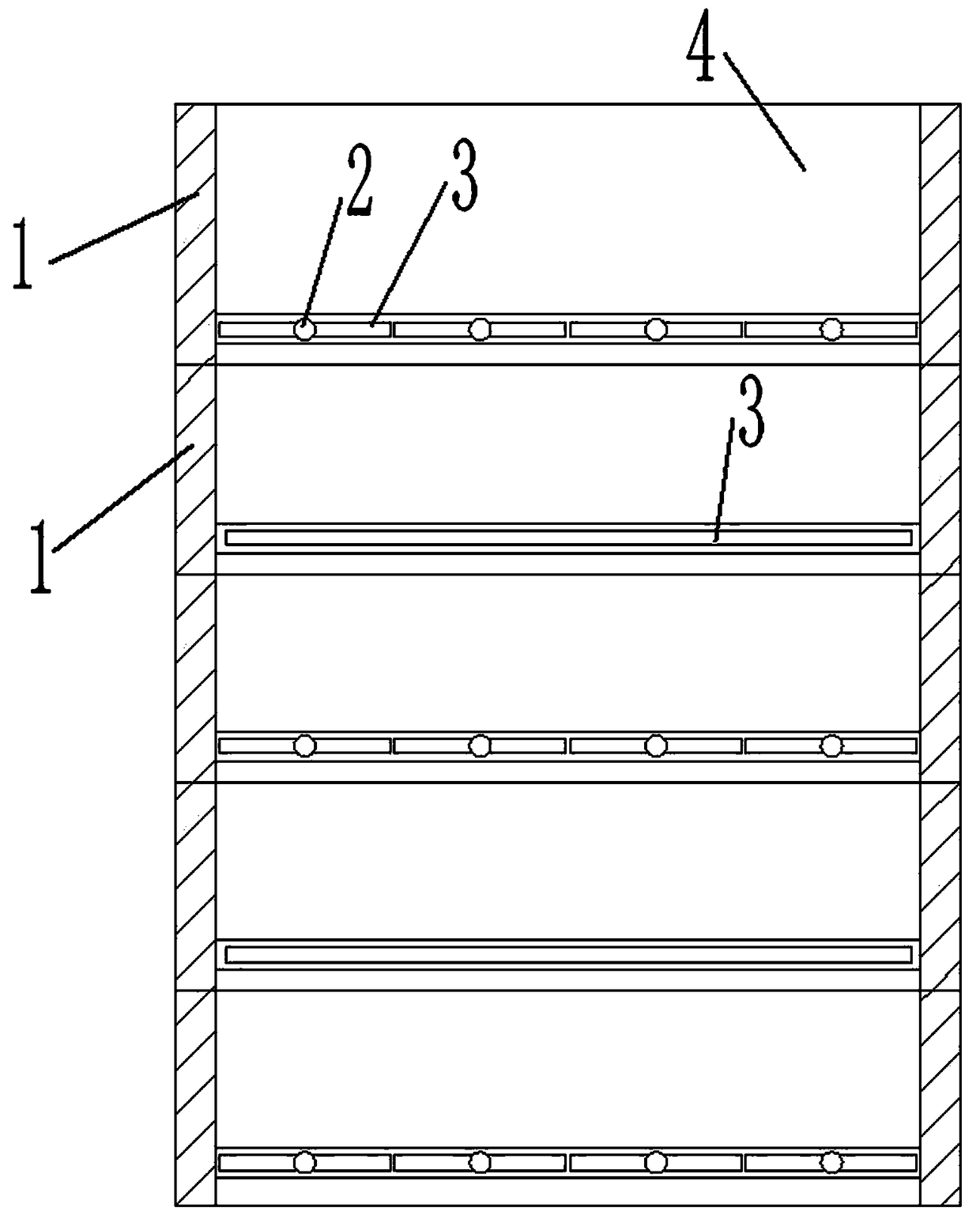

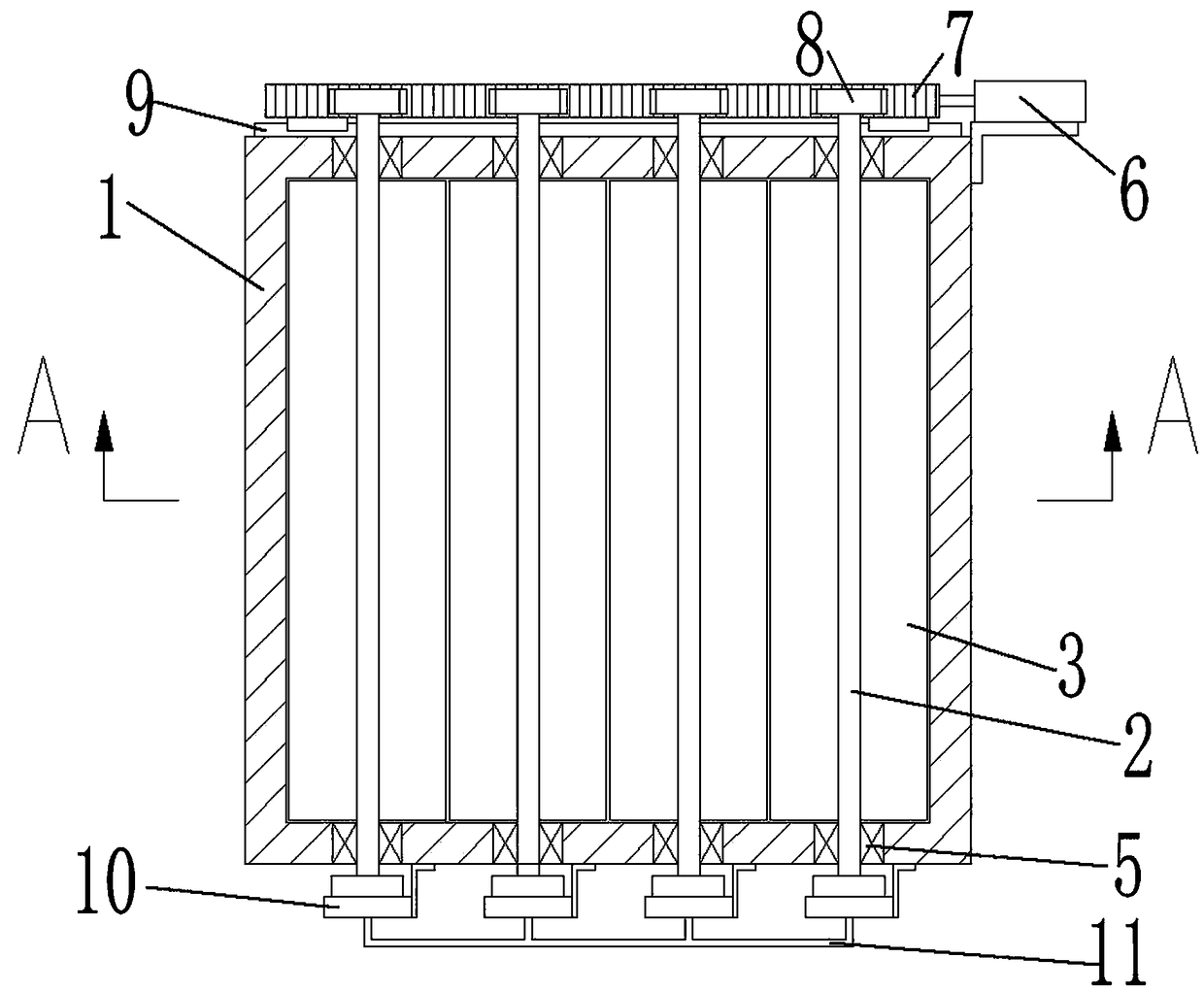

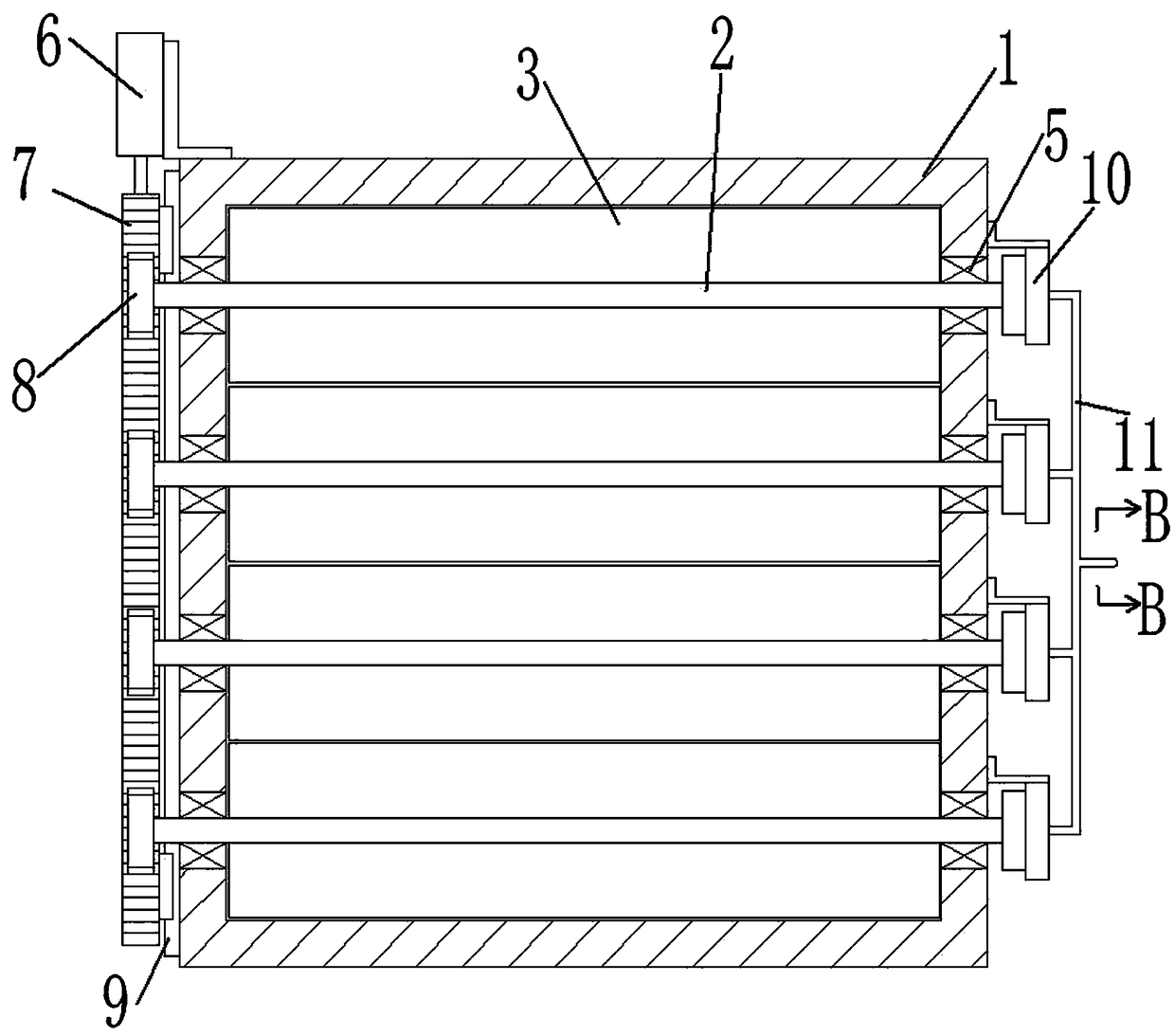

[0025] Attached below figure 1 to attach Figure 6 The present invention will be further described.

[0026] A continuous black tea fermentation machine, comprising: N sub-fermentation chambers 1 stacked from top to bottom, N being a positive integer greater than or equal to 2, sub-fermentation chambers 1 are sealed around and open at the upper and lower ends, and a fermentation chamber 4 is formed inside Several rotating shafts 2 are arranged at equal intervals in each fermentation chamber 4, and the two ends of the rotating shaft 2 are horizontally rotated and installed on the sub-fermentation chamber 1 through bearings 5, respectively. The distance between two adjacent turning plates 3 is smaller than the outer diameter of the black tea leaf, and the distance between the outermost turning plate 3 and the inner wall of the sub-fermentation chamber 1 is smaller than the outer diameter of the black tea leaf; On the fermentation chamber 1, it is used to drive the rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com