Composite gel fat substitute and low-fat egg tart filling prepared therefrom

A fat substitute and composite gel technology, which is applied in the field of low-fat egg tart fillings, can solve the problems of rare composite gels and poor hydrophilicity, achieve good flavor and consumer acceptance, delicate surface layer, plump and smooth appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

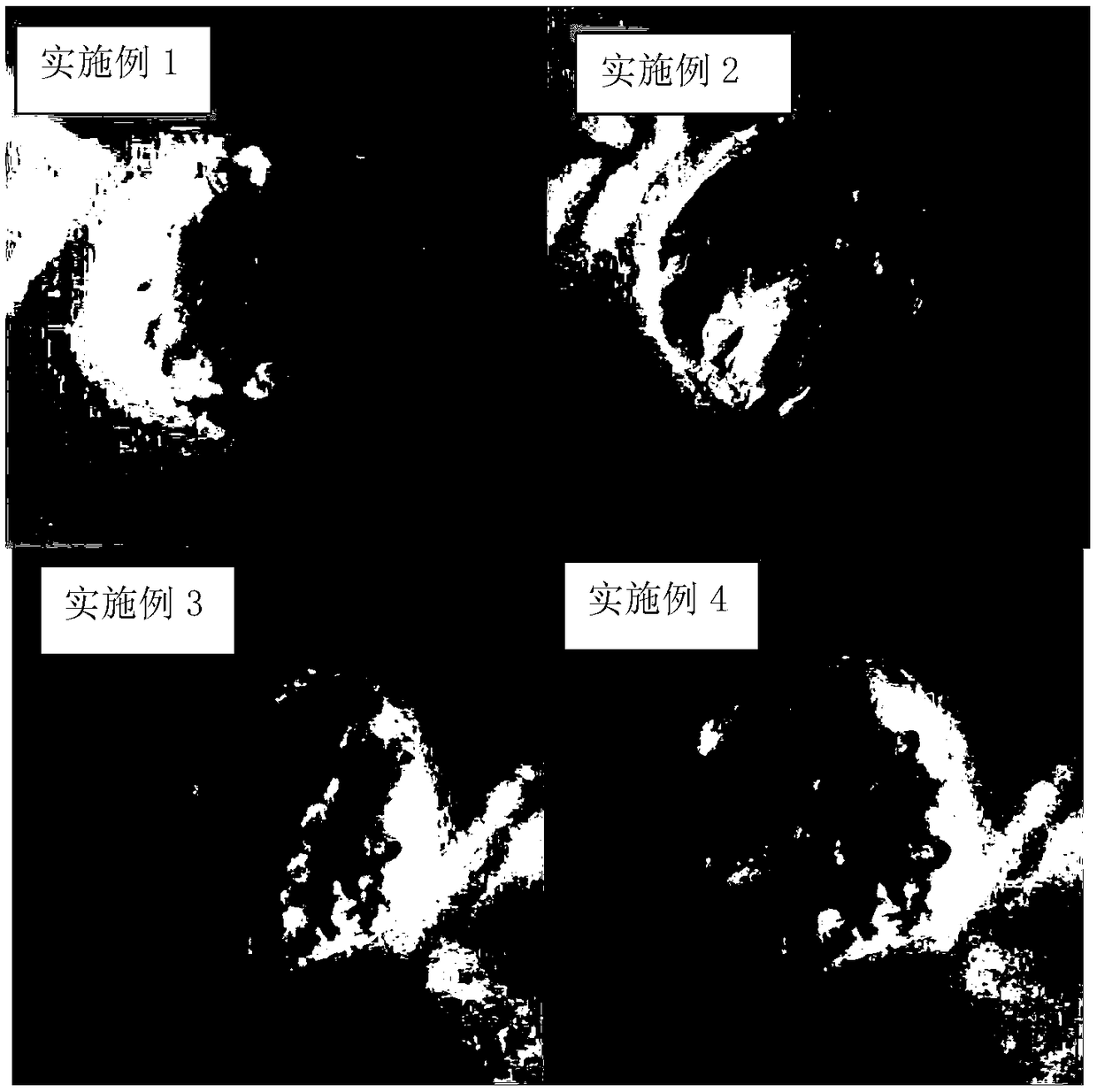

Embodiment 1

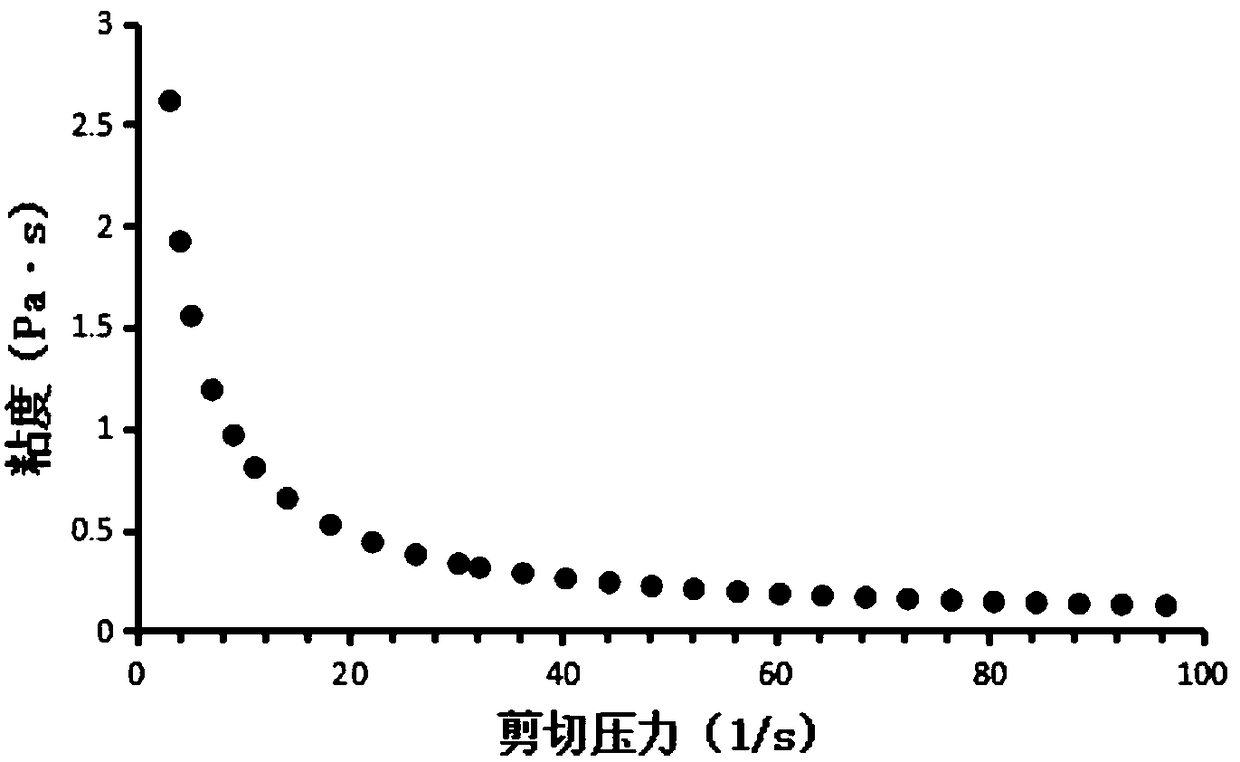

[0038] (1) xanthan gum solution, gum arabic solution and modified citrus pectin solution that the preparation mass concentration is 1%; solution and xanthan gum solution were mixed to obtain a mixed colloid solution, the mixed colloid solution was used as the matrix fluid, and the modified citrus pectin solution was used as the ejection fluid; The speed is introduced into the mixing reaction chamber, and the obtained reactant is a pseudoplastic semi-solid fat substitute similar to grease, that is, a composite gel fat substitute. Use rheometer to measure the rheological properties of the product, the results are as follows: figure 1 shown.

[0039] (2) Prepare raw materials by weight: 17 parts of whipped cream, 12 parts of eggs, 14 parts of milk, 4 parts of white sugar, and 4 parts of compound gel fat substitute.

[0040] (3) The egg white and egg yolk in the eggs are separated and processed through a 100-mesh sieve.

[0041] (4) Add egg yolk and whipped cream to milk for mi...

Embodiment 2

[0046] (1) preparation mass concentration is respectively 0.8%, 1.0%, 0.8% xanthan gum solution, acacia gum solution and modified citrus pectin solution; get the same volume of acacia gum solution and xanthan gum solution and mix to get mixed colloid solution , the mixed colloid solution was used as the base fluid, and the modified citrus pectin solution was used as the ejector fluid, with a volume ratio of 2:3; the temperature was controlled at 90°C, the working pressure was 0.4MPa, and the solutions were introduced into the mixture at a speed of 6mL / min. In the reaction chamber, the obtained reactant is a pseudoplastic semi-solid fat substitute similar to grease, that is, a composite gel fat substitute.

[0047] (2) Prepare raw materials by weight: 14 parts of whipped cream, 10 parts of eggs, 16 parts of milk, 3 parts of white sugar, and 6 parts of compound gel fat substitute.

[0048](3) The egg white and egg yolk in the eggs are separated and processed through a 100-mesh s...

Embodiment 3

[0054] (1) preparation mass concentration is respectively 1.2%, 0.8%, 1.0% xanthan gum solution, Arabic gum solution and modified citrus pectin solution; get Arabic gum solution and xanthan gum solution and mix with 2:3 volume ratio to obtain Mixed colloids, the mixed colloid solution is used as the matrix fluid, and the modified citrus pectin solution is used as the ejector fluid, and the mass ratio is 1:1; the temperature is controlled at 75 ° C, the working pressure is 0.5 MPa, and the solutions are respectively injected at a speed of 8 mL / min. Introduced into the mixing reaction chamber, the obtained reactant is a pseudoplastic semi-solid fat substitute similar to grease, that is, a composite gel fat substitute.

[0055] (1) Prepare raw materials by weight: 12 parts of whipped cream, 12 parts of eggs, 12 parts of milk, 5 parts of white sugar, and 10 parts of compound gel fat substitute.

[0056] (2) The egg white and egg yolk in the eggs are separated and processed through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com