High pressure chamber device in small high-pressure experimental device

A high-pressure experiment and high-pressure chamber technology, applied in the field of high-pressure chamber devices, can solve the problems of damaged diamond, high price, and diamond that cannot be reused.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

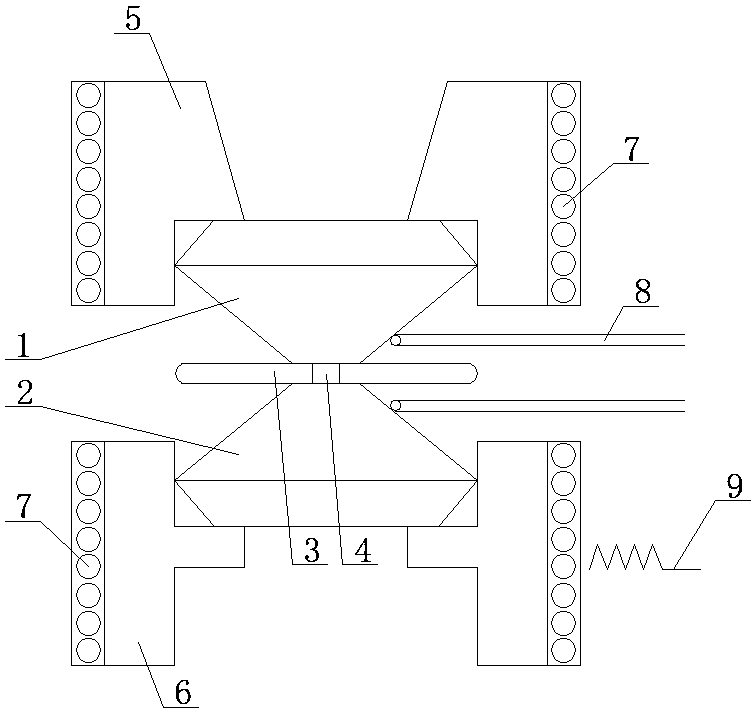

[0017] A high-pressure chamber device in a small-scale high-pressure experimental device, such as figure 1 As shown: it includes upper alumina press drill 1, lower alumina press drill 2, gasket 3, sample chamber 4, upper tungsten carbide base 5, lower tungsten carbide base 6, molybdenum resistance wire 7, thermocouple 8, Power supply 9, a gasket 3 is provided between the upper alumina press drill 1 and the lower alumina press drill 2, the gasket 3 is a brass sheet or phosphor bronze sheet, and the center hole on the brass or phosphor bronze gasket 3 A completely closed sample chamber is formed. The upper and lower anvils can obtain high pressure in the sample chamber during the process of pressing the brass or phosphor bronze gasket 3. When performing high temperature and high pressure experiments, a good pressure transmission medium such as Methanol: ethanol = 4:1 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com