Preparation method of monodisperse triangular nano-silver

A monodisperse, nano-silver technology, applied in the direction of nanotechnology, can solve the problems of inability to repeat experiments, and achieve the effect of guaranteed success rate of experiments, high output, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

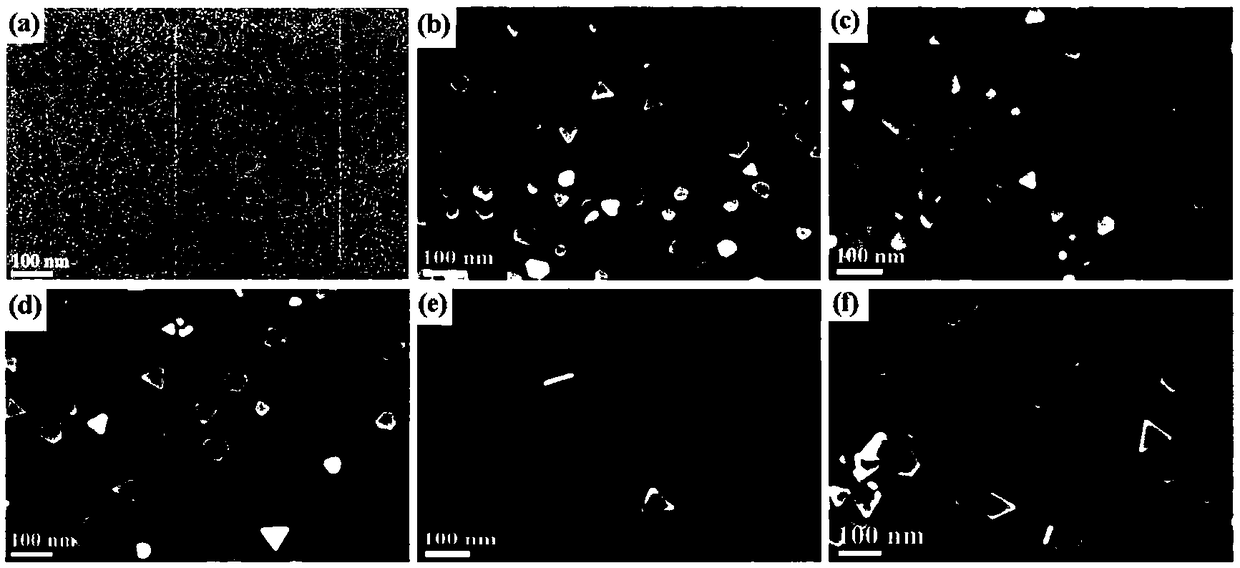

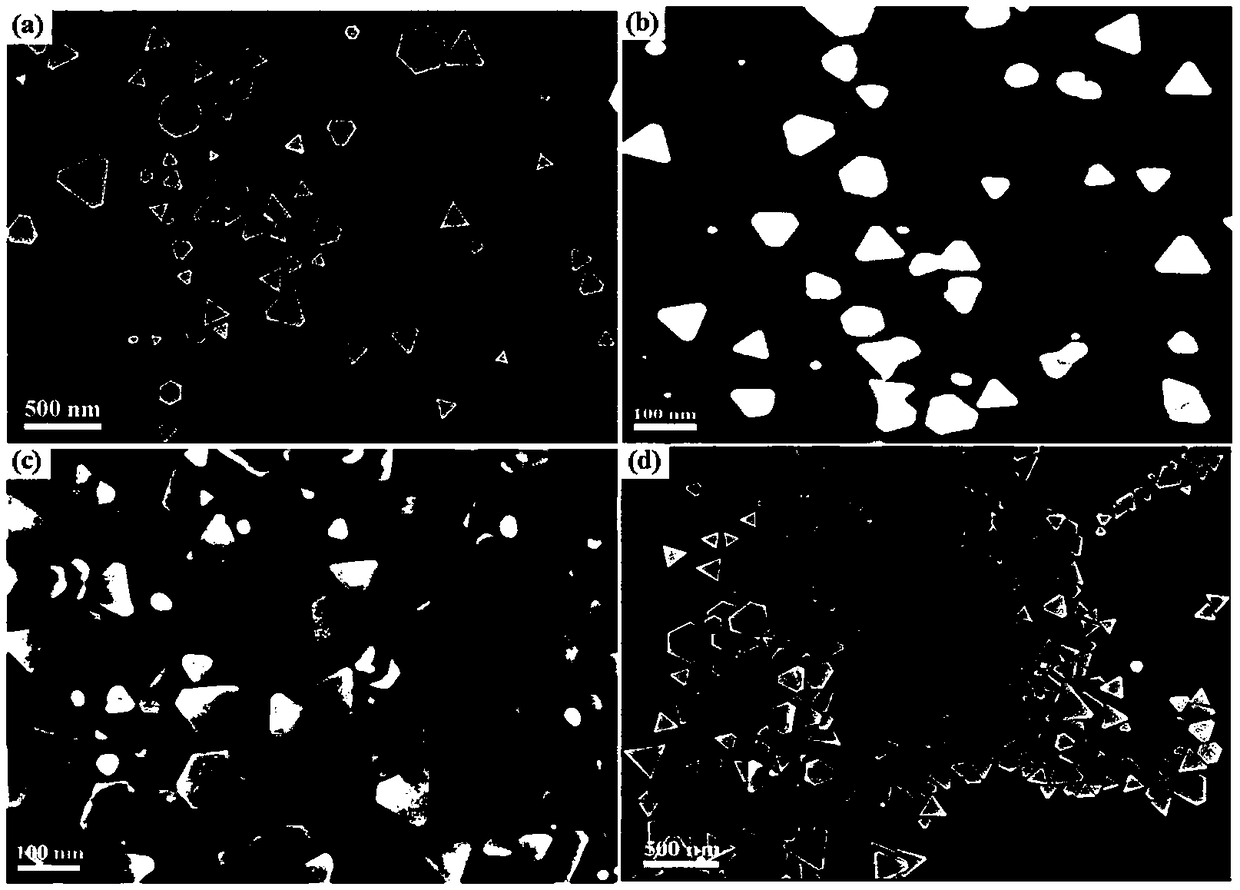

[0034] Embodiment 1: average side length is 35 ± 4nm ( figure 1 A) the preparation method of triangular nano-silver flakes, the steps are:

[0035] (1) Add 60mL of n-amyl alcohol into a stoppered Erlenmeyer flask, and add 1.8g of PVP (Mw=30000g.mol) under stirring –1 ), drop 500 μL NaOH / n-pentanol saturated solution, and stir evenly.

[0036] (2) While stirring, add 3.9mL of AgNO with a concentration of 1.2wt% into the Erlenmeyer flask 3 For the aqueous solution, continue to stir for 30 minutes to form a ternary solution system of n-pentanol / PVP / water and put it into a 95°C thermostat for heat treatment for 40 hours;

[0037] (3) centrifuging the heat-treated reaction solution to obtain triangular nano-silver flakes.

Embodiment 2

[0038] Embodiment 2: average side length is 55 ± 5nm ( figure 1 The preparation method of the triangular nano-silver sheet of b), its steps are:

[0039] (1) Add 60mL of n-amyl alcohol into a stoppered Erlenmeyer flask, and add 1.8g of PVP (Mw=30000g.mol) under stirring –1 ), drop 350 μL NaOH / n-pentanol saturated solution, and stir evenly.

[0040] (2) While stirring, add 3.9mL of AgNO with a concentration of 1.2wt% into the Erlenmeyer flask 3 For the aqueous solution, continue to stir for 30 minutes to form a ternary solution system of n-pentanol / PVP / water and put it into a 95°C thermostat for heat treatment for 37 hours;

[0041] (3) centrifuging the heat-treated reaction solution to obtain triangular nano-silver flakes.

Embodiment 3

[0042] Embodiment 3: average side length is 70 ± 7nm ( figure 1 D) the preparation method of triangular nano-silver flakes, the steps are:

[0043] (1) Add 60mL of n-amyl alcohol into a stoppered Erlenmeyer flask, and add 1.8g of PVP (Mw=30000g.mol) under stirring –1 ), drop 175 μL NaOH / n-pentanol saturated solution, and stir evenly.

[0044] (2) While stirring, add 3.9mL concentration of 0.6wt% AgNO into the Erlenmeyer flask 3 For the aqueous solution, continue to stir for 30 minutes to form a ternary solution system of n-pentanol / PVP / water and put it into a 95°C thermostat for heat treatment for 32 hours;

[0045] (3) centrifuging the heat-treated reaction solution to obtain triangular nano-silver flakes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com