Solid tire for industrial and mining heavy-load vehicle and manufacturing method thereof

A technology for solid tires and manufacturing methods, applied to vehicle parts, tire parts, non-pneumatic tires, etc., can solve the problems of thick polyurethane solid tire rubber layer, reduced driving comfort, and reduced rubber layer thickness, etc., to achieve environmental friendliness type, reduce environmental pressure, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

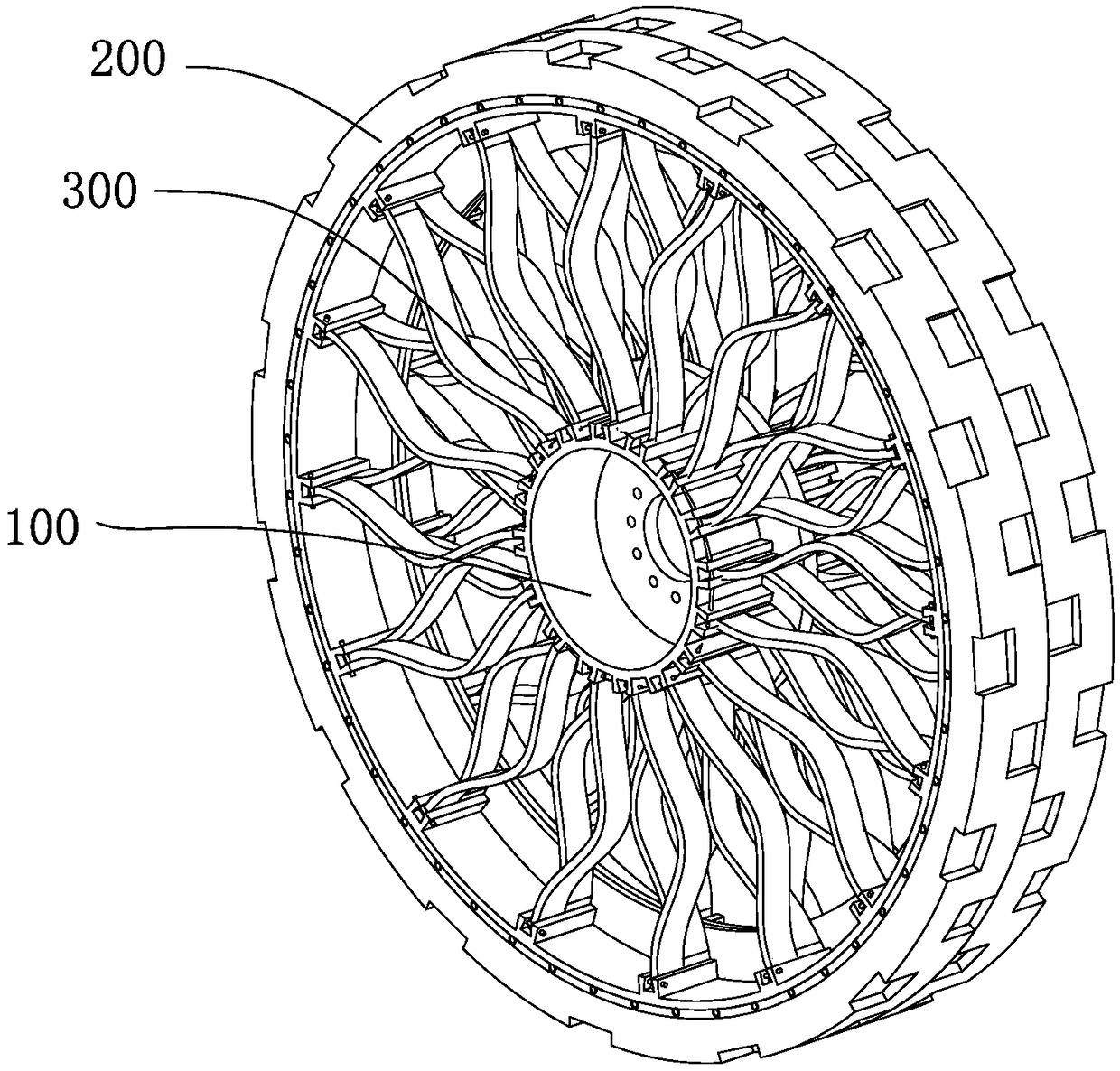

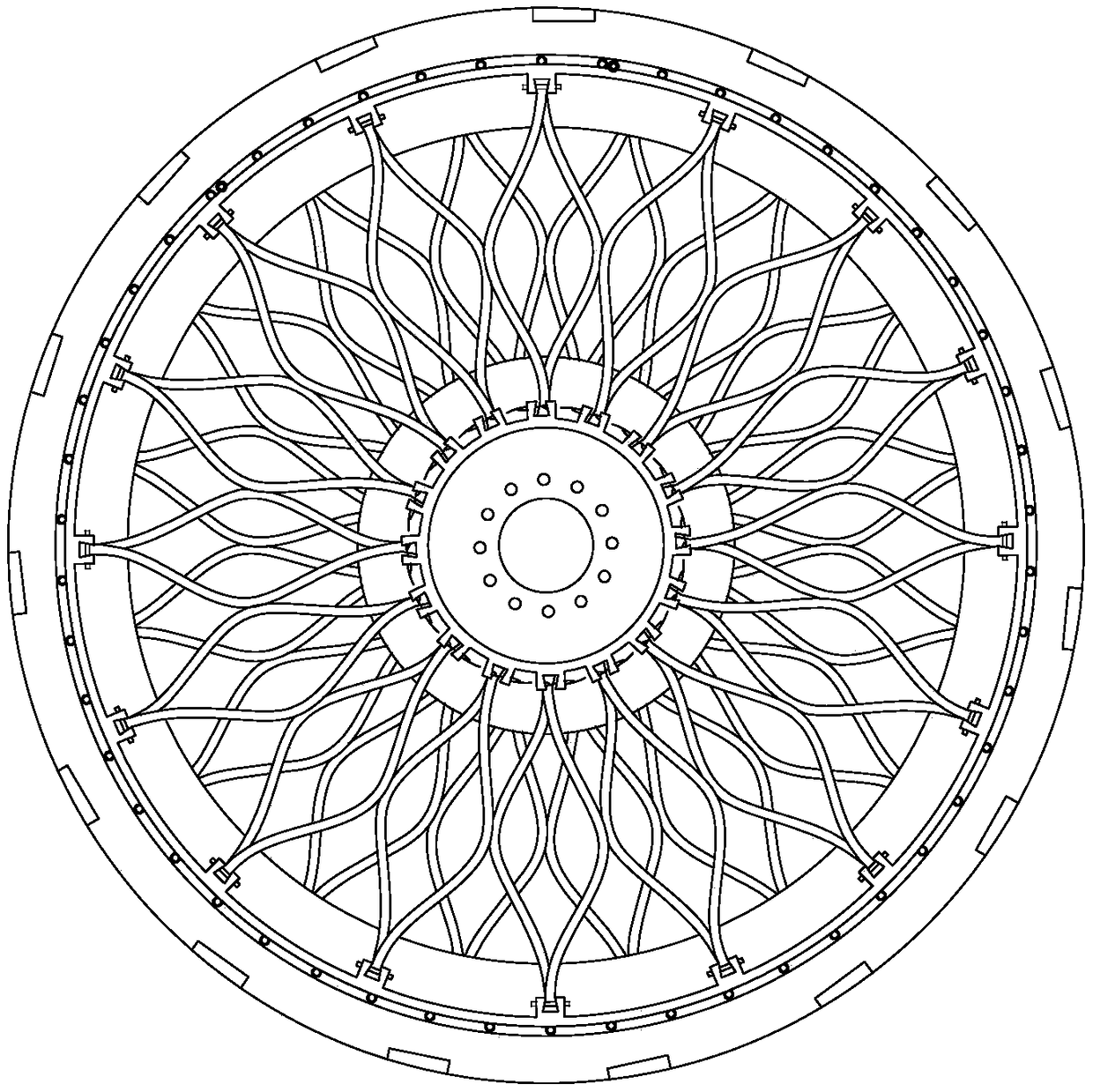

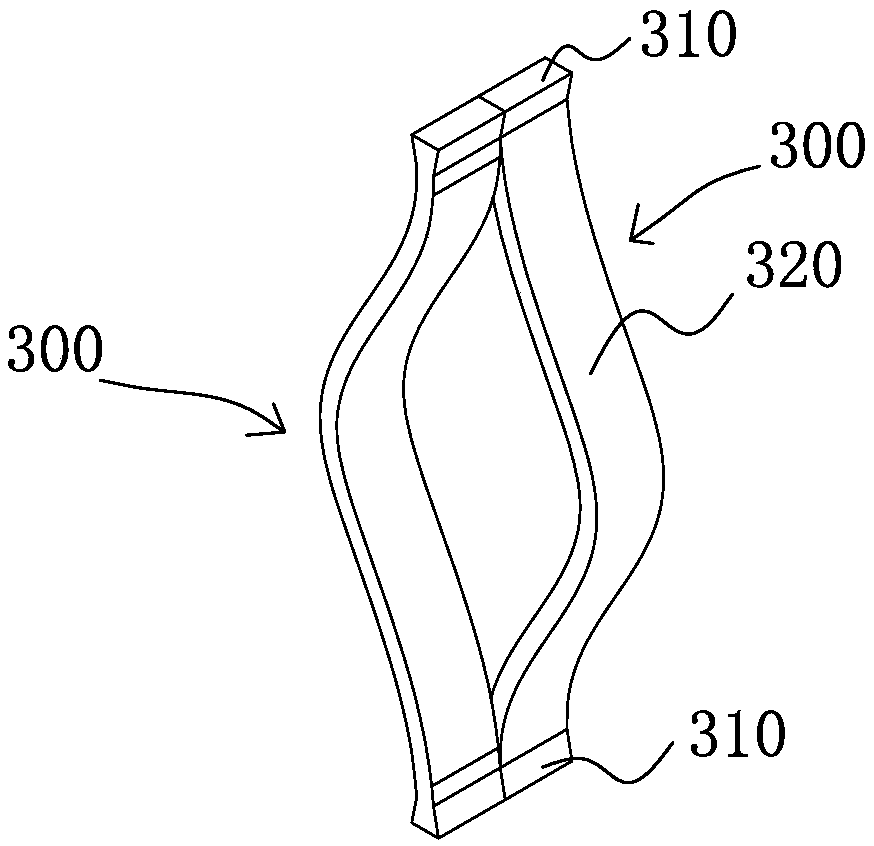

[0062] Embodiment one, refer to figure 1 ,and figure 2 , the solid tire, similar to the traditional heavy-duty solid tire structure, is composed of a steel component part and a rubber part, wherein the steel component part provides the hub, spokes and rims, and the rubber part provides elastic support for the tread. The solid tires formed must have smooth driving performance, comfort, durability, and weather resistance, while minimizing their own weight. In the logic of the following instructions, the introduction is gradually introduced from the hub to the tread part, in order to obtain a clear logical sequence.

[0063] hub part 100, ref. Figure 10 and Figure 9 , including the flange part 110 and the cylindrical part 120 located on both sides of the flange part, the whole is made of carbon steel, and can be partially or integrally heat treated as required. The heat treatment process is the same as that of the wheel hub and rim manufacturing technology in the prior art....

Embodiment 2

[0097] Embodiment two, refer to Figure 11 , the cord layer is omitted in this embodiment in order to simplify the manufacturing process.

Embodiment 3

[0098] Embodiment three, refer to Figure 12 , in this embodiment, there are multiple protrusions on the heat-conducting rubber, which has a better heat dissipation effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com