Motor assembly system with built-in speed reducer

A reducer and assembly technology, applied in the field of motor assembly system, can solve problems such as unstable working conditions, reduced reliability, and harsh working environment of hub motors, so as to improve controllability and stability, reduce axial size, Improve the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

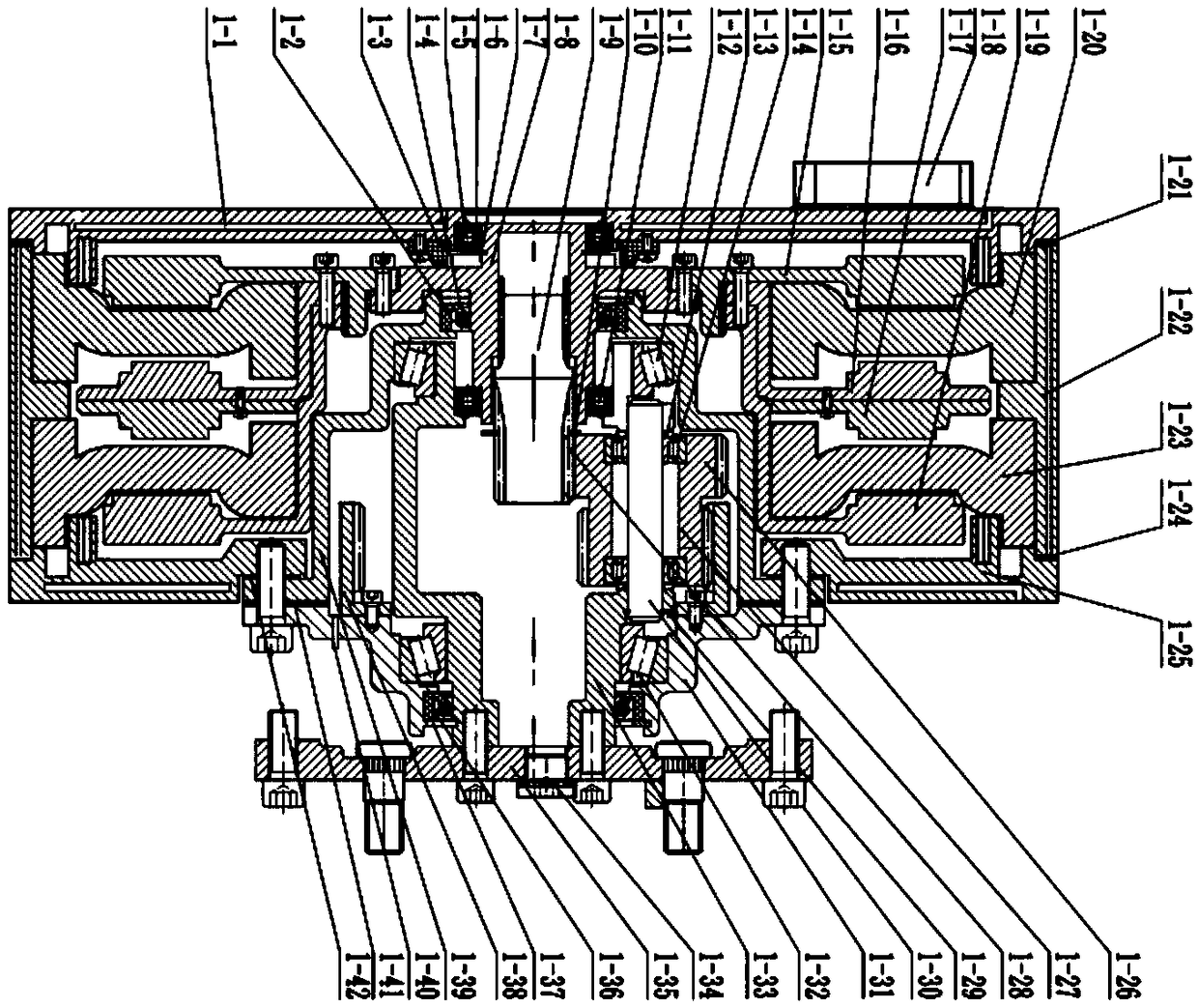

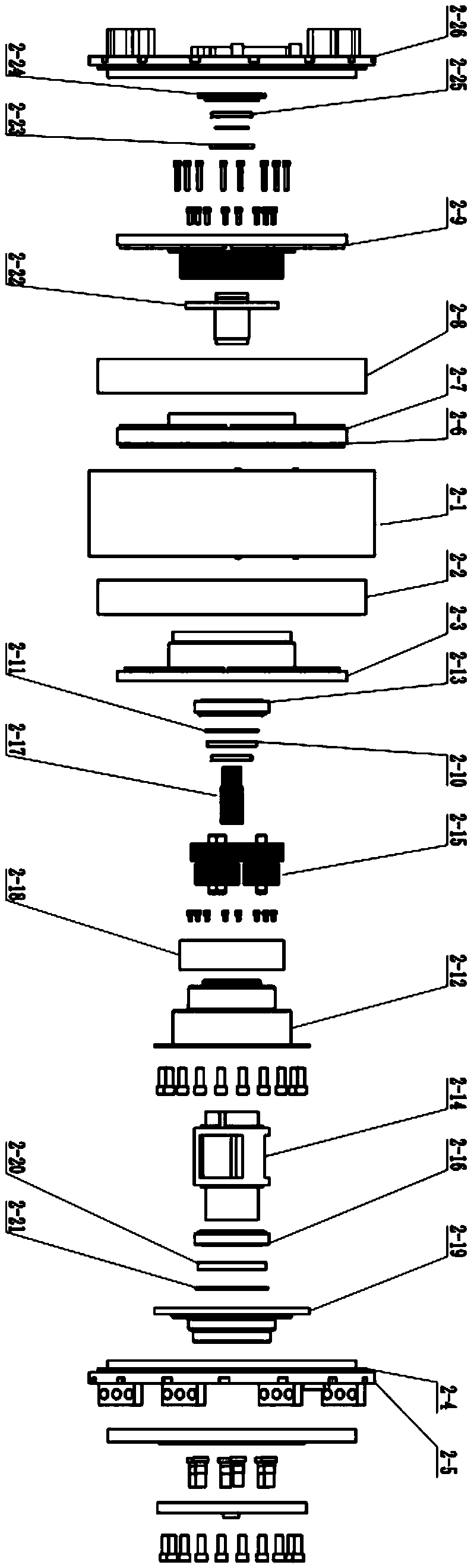

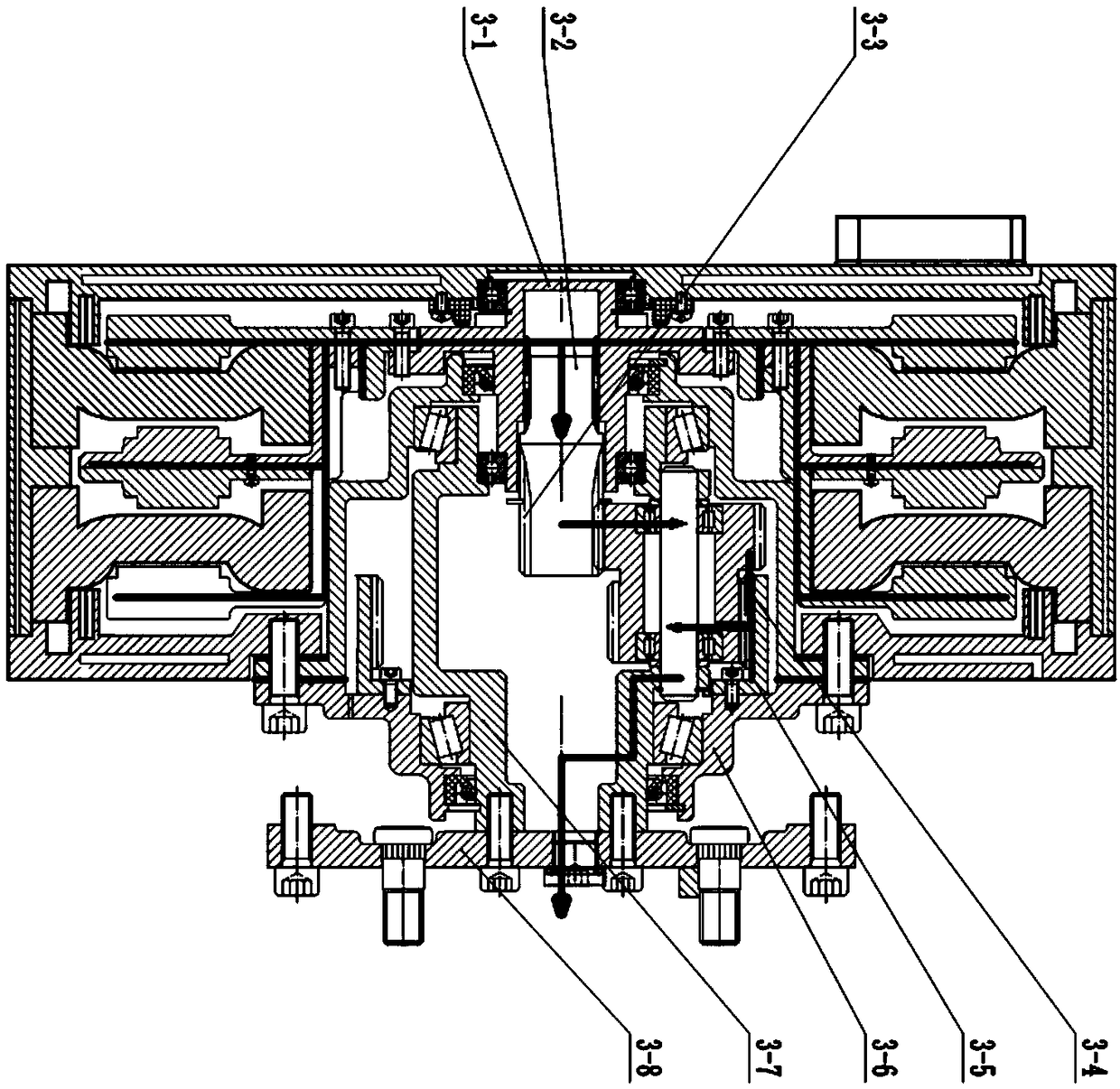

[0056] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0057] For electric drive devices, restricted by actual working conditions, the available space of the system is often small, but the power demand is high, and the driving capacity of the motor is often positively related to its size, volume, and quality, and the volume and mass of the reducer are also related to the transmission capacity. Proportional, obviously, this is contrary to the actual conditions. Most of the existing technical solutions make the motor and the reducer into independent transmission. The disadvantage is that it occupies a large working space. Under some conditions with high requirements for actual sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com