Method for preparing chlorphenesin by using micro-channel continuous flow reactor

A technology of chlorphenesin and reactor, which is applied in the field of microchannel continuous flow reactor to prepare chlorphenesin, can solve the problems of low conversion rate of raw materials, potential safety hazards, small heat exchange area, etc., and achieve simple and efficient reaction process , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

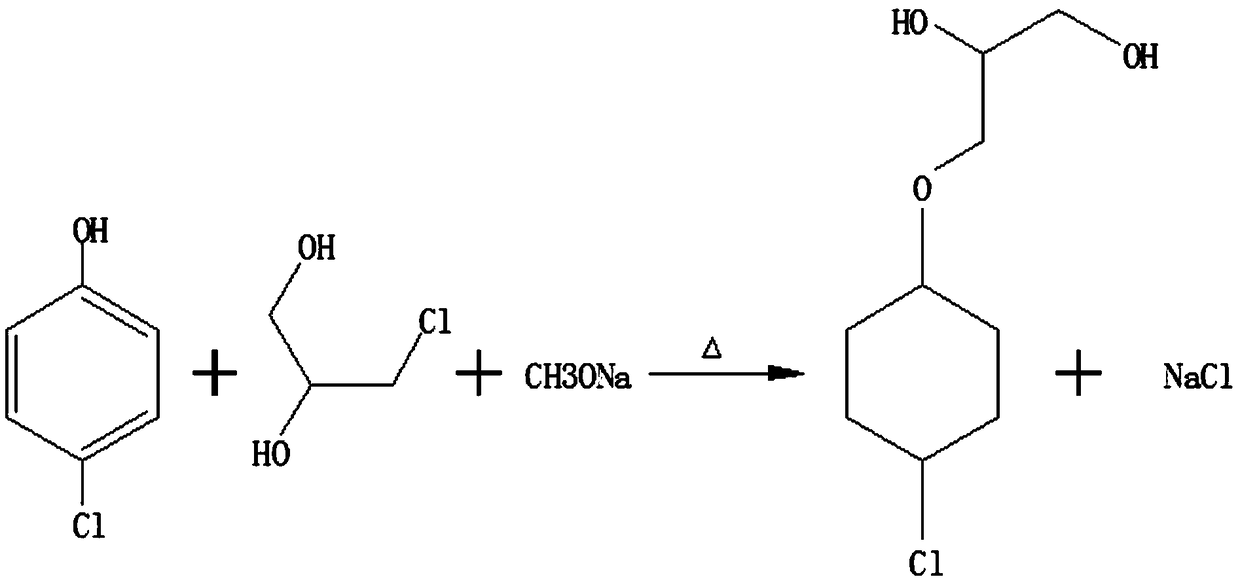

Image

Examples

Embodiment 1

[0017] a) Put 1 mol of chlorophenol and 1.02 mol of 3-chloro-1,2-propanediol into volumetric flask A with a volume of 1L, add 500ml of methanol and stir to dissolve, after completely dissolved, add methanol again to make the volume to 1L, Add 1.02mol30% liquid sodium methoxide to 500ml volumetric flask B, and use methanol to set the volume to 500ml, then connect volumetric flask A to the microchannel continuous flow reactor produced by Shandong Haomai Machinery Technology Co., Ltd. with a constant flow pump, Adjust the flow rate to 1ml / s, connect the volumetric flask B to the microchannel continuous flow reactor produced by Shandong Haomai Machinery Technology Co., Ltd. with a constant flow pump, adjust the flow rate to 0.6ml / s, and set the temperature at 60°C , carry out the etherification reaction, receive the reaction liquid with the flask to obtain the semi-finished product A;

[0018] b) Leave the semi-finished product A obtained in step a) to cool naturally to 30°C, plac...

Embodiment 2

[0021] a) Put 1 mol of chlorophenol and 1.02 mol of 3-chloro-1,2-propanediol into volumetric flask A with a volume of 1L, add 505ml of methanol and stir to dissolve, after completely dissolved, add methanol again to make the volume to 1L, Add 1mol30% liquid sodium methoxide into 500ml volumetric flask B, and adjust the volume to 500ml with methanol, and connect volumetric flask A to the microchannel continuous flow reactor produced by Shandong Haomai Machinery Technology Co., Ltd. using a constant flow pump. Adjust the flow rate to 1.2ml / s, connect the volumetric flask B to the microchannel continuous flow reactor produced by Shandong Haomai Machinery Technology Co., Ltd. with a constant flow pump, adjust the flow rate to 0.6ml / s, and set the temperature at 500°C , carry out the etherification reaction, receive the reaction liquid with the flask to obtain the semi-finished product A;

[0022] b) Leave the semi-finished product A obtained in step a) to cool naturally to 30°C, p...

Embodiment 3

[0025] a) Put 1 mol of chlorophenol and 1.2 mol of 3-chloro-1,2-propanediol into volumetric flask A with a volume of 1L, add 520ml of methanol and stir to dissolve, after completely dissolved, add methanol again to make the volume to 1L, Add 1 mol of 30% liquid sodium methoxide into 500ml volumetric flask B, and make the volume to 500ml with methanol, connect volumetric flask A to the continuous flow reactor produced by Corning Company of the United States with a constant flow pump, and adjust the flow rate to 1.2ml / second, the volumetric flask B is connected to the microchannel continuous flow reactor produced by Corning Corporation of the United States using a constant flow pump, the flow rate is adjusted to 0.4ml / s, the temperature is set at 700 ° C, and the etherification reaction is carried out. Receive the reaction solution to obtain the semi-finished product A;

[0026] b) Leave the semi-finished product A obtained in step a) to cool naturally to 25°C, put the cooled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com