Basalt composite material, and preparation method and application thereof

A composite material and basalt technology, applied in the field of basalt composite material and its preparation, can solve the problems of high production cost, expensive carbon fiber, overweight car body, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of basalt composite material, comprises the following steps:

[0026] a) mixing the resin material with the curing agent to obtain a colloidal solution;

[0027] b) fully contacting the colloidal solution obtained in step a) with basalt fibers under vacuum conditions, and then curing to obtain a basalt composite material;

[0028] The monofilament diameter of the basalt fiber is 6 μm to 15 μm, and the surface density is 270 g / m 2 ~330g / m 2 ;

[0029] The mass ratio of the colloid solution to the basalt fiber is (2.6-4.3):7.5.

[0030] In the present invention, firstly, the resin material and the curing agent are mixed to obtain a colloidal solution. In the present invention, the resin material is preferably selected from one or more of vinyl resins, epoxy resins, polyurethane resins and phenolic resins, more preferably epoxy resins or phenolic resins. The present invention has no special limitation on the source o...

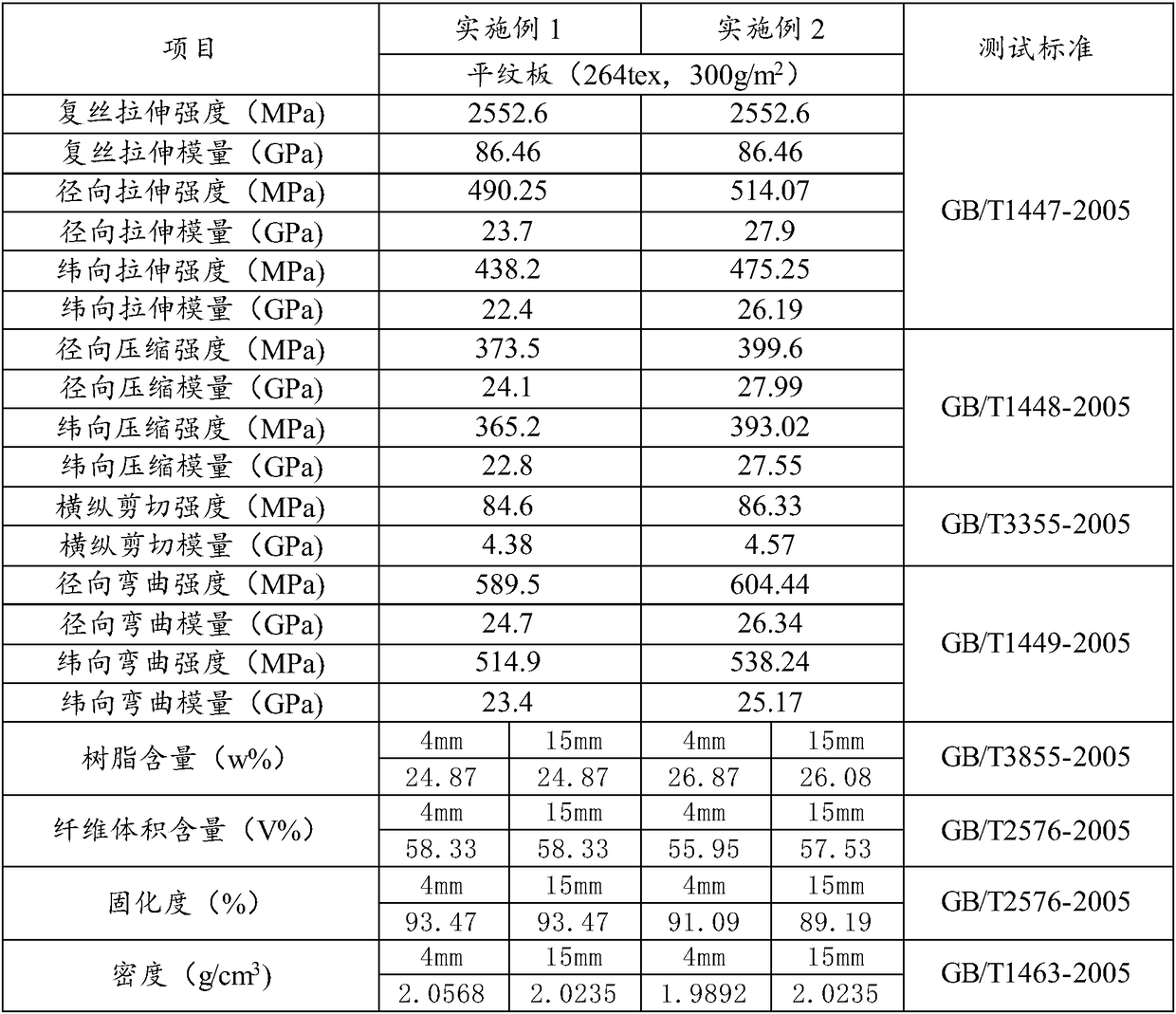

Embodiment 1

[0054] Wipe the surface of the mold with 1.5 parts by weight of release agent, and then lay 75 parts by weight of cut basalt fiber cloth on the mold, then cover the release cloth in turn, spread the diversion net, lay the vacuum film, and then vacuumize To a vacuum degree of 0.092MPa ~ 0.095MPa;

[0055] The phenolic resin of 25 parts by weight and the hexahydrophthalic anhydride of 5 parts by weight are mixed uniformly in the resin tank to form a colloidal solution, and then the above-mentioned colloidal solution is immersed in the mold through a draft tube to make the basalt fiber cloth in the mold Fully contact with the colloidal solution;

[0056] After the above-mentioned mold is completely immersed in the colloidal solution, put it into an oven and cure it at 50°C for 2 hours, then take out the mold and demold it to obtain a basalt composite material;

[0057] The obtained basalt composite material is scored, cut, polished, repaired and assembled to further obtain a toy...

Embodiment 2

[0059] Wipe the surface of the mold with 1.5 parts by weight of release agent, and then lay 75 parts by weight of cut basalt fiber cloth on the mold, then cover the release cloth in turn, spread the diversion net, lay the vacuum film, and then vacuumize To a vacuum degree of 0.092MPa ~ 0.095MPa;

[0060] Mix 25 parts by weight of epoxy resin and 5 parts by weight of 4,4'-diaminodiphenylmethane in a resin tank to form a colloidal solution, and then immerse the above colloidal solution into the mold through a draft tube, so that The basalt fiber cloth in the mold fully contacts with the colloidal solution;

[0061] After the above-mentioned mold is completely immersed in the colloidal solution, put it into an oven and cure it at 90°C for 2 hours, then take out the mold and demold it to obtain a basalt composite material;

[0062] The obtained basalt composite material is scored, cut, polished, repaired and assembled to further obtain a toy car body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com