Nano fiber and preparing method thereof

A nanofiber and melamine technology, applied in the field of nanofibers and their preparation, can solve the problems such as no public reports on the preparation method of melamine-phloroglucinol-formaldehyde resin nanofibers, and achieve easy large-scale production and good adsorption. Ability, simple effect of preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

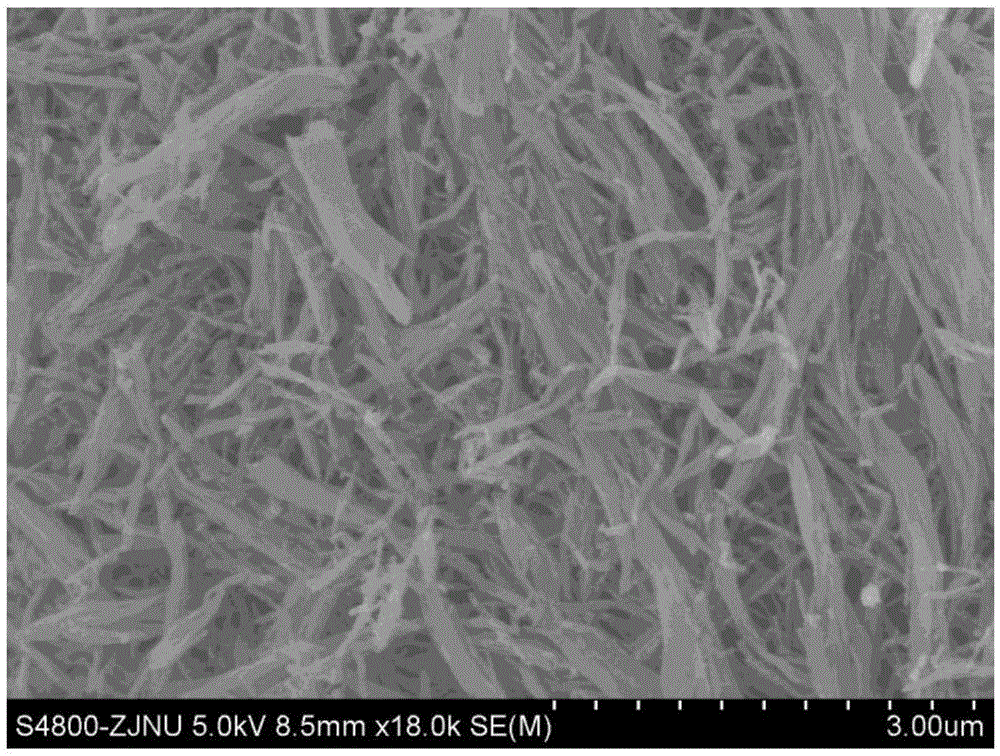

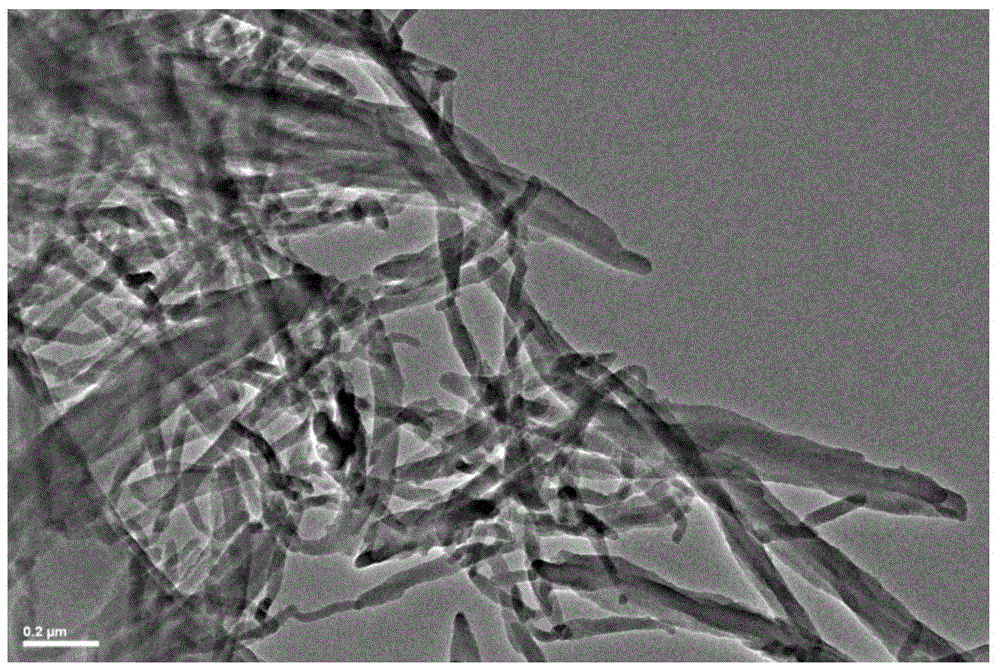

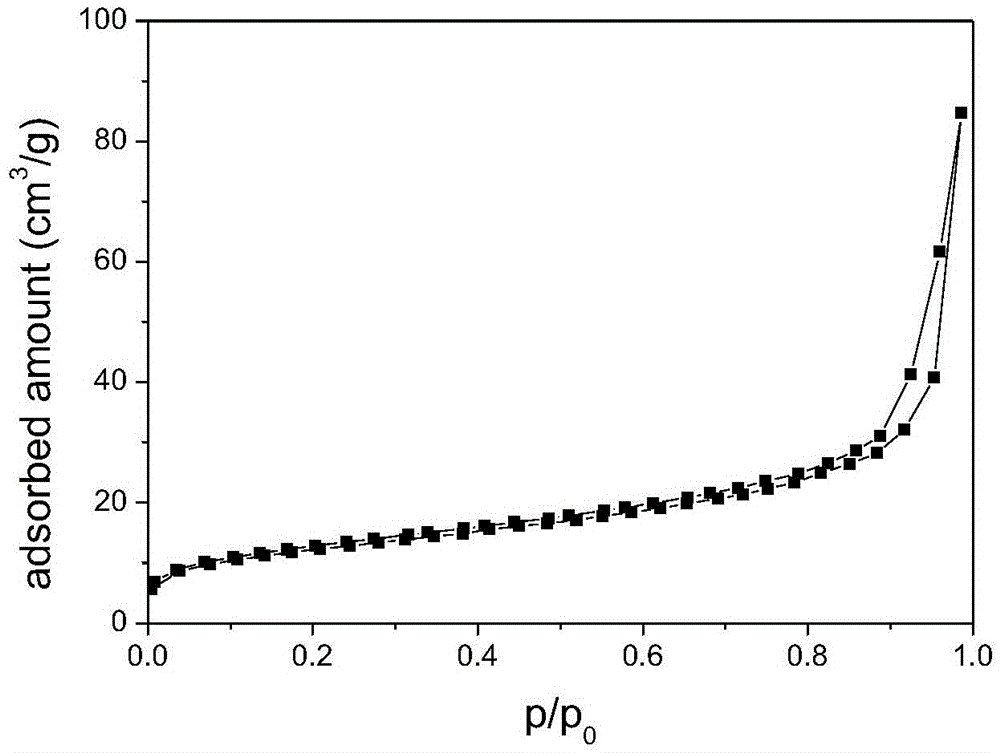

[0036] Add 4.4g of phloroglucinol to 40g of deionized water, stir and dissolve at 40°C, continue to add 8.5g of formaldehyde solution with a mass fraction of 37%, stir for 100min, and record it as solution A; add 4.4g of melamine to 40g of deionized water, After stirring and dissolving at 70°C, add 8.5g of 37% formaldehyde solution. After stirring for 10 minutes, the solution becomes clear, which is recorded as solution B; add solution B to solution A, and continue stirring for 30 minutes. After the system is uniform, place it at 95°C Reaction in the oven for 24h. Suction filtration, washing, and overnight drying of the filter cake at 60°C to obtain the product. SEM images and TEM images show that the prepared samples are nanofibers with a diameter of 20-100nm. For SEM images, see figure 1 , TEM image see figure 2 . -196°CN 2 Adsorption-desorption isotherms at relative pressure p / p 0 There is an adsorption amount at 0 = There is a large amount of adsorption at 0.9~1.0 ac...

Embodiment 2

[0038] The preparation steps are the same as in Example 1, and the raw material ratio and reaction conditions are shown in Table 1. SEM images and TEM images show that the prepared samples are nanofibers with a diameter of 10-30nm. For SEM images, see Figure 5 , TEM image see Image 6 . -196°CN 2 The BET specific surface area of the sample for adsorption determination is 143m 2 / g, the total pore volume is 0.30cm 3 / g.

Embodiment 3

[0040] The preparation steps are the same as in Example 1, and the raw material ratio and reaction conditions are shown in Table 1. SEM images and TEM images show that the prepared samples are nanofibers with a diameter of 30-200nm. For SEM images, see Figure 7 , TEM image see Figure 8 . -196°CN 2 The BET specific surface area of the sample for adsorption determination is 22m 2 / g, the total pore volume is 0.06cm3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com