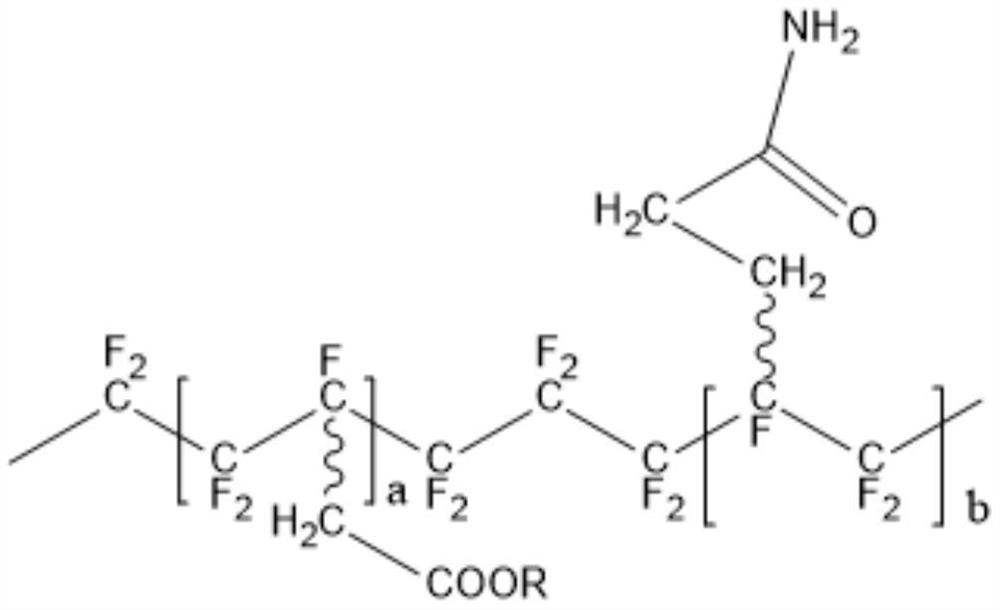

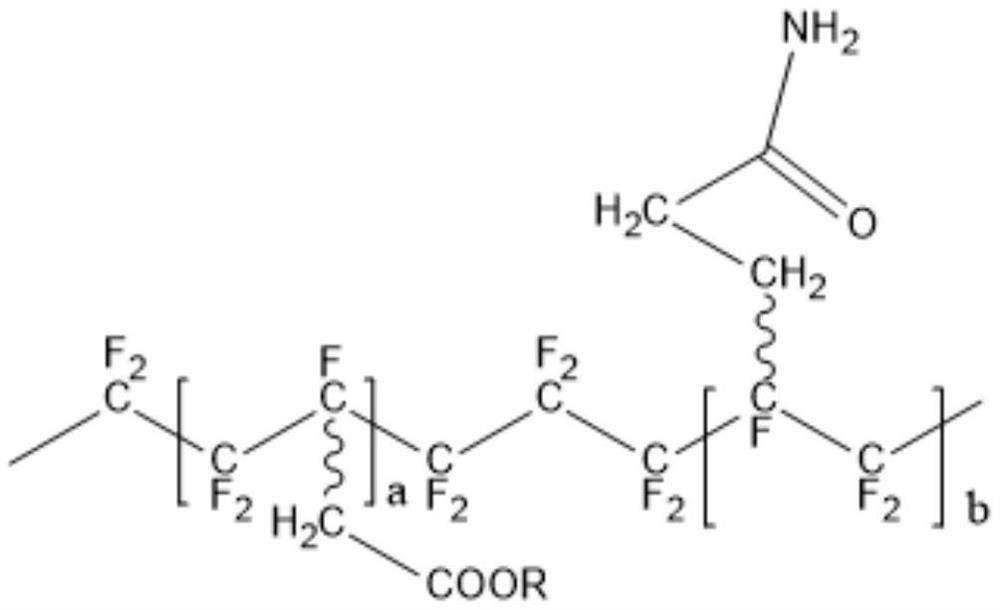

Acrylate and acrylamide grafted polytetrafluoroethylene and highlight mirror surface wear-resistant flame-retardant polycarbonate material

A technology of flame retardant polycarbonate and PTFE, applied in the field of flame retardant materials, can solve the problems of exposed PTFE, high processing temperature, and easy cracking of the coating, so as to achieve easy operation and improve surface gloss. , the method is efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Preparation of polytetrafluoroethylene anti-dripping agent A grafted with methyl acrylate and acrylamide

[0058] (1) Treat ultrafine polytetrafluoroethylene powder M530 and sodium-naphthalene treatment liquid according to 1:10 (molar ratio) for 10 minutes, then use acetone suction filtration to wash 5 times to remove excess sodium-naphthalene treatment liquid and organic impurities, Rinse with distilled water for 5 times to remove water-soluble impurities, and dry at 50°C to obtain activated polytetrafluoroethylene powder.

[0059] (2) 200g of activated polytetrafluoroethylene powder is added to the 2000g ethanol solution of methyl acrylate and acrylamide, wherein the concentration of methyl acrylate is 40wt%, and the concentration of acrylamide is 5wt%. React for 20 hours. After the reaction, the product was first washed with acetone for 3 times, and then repeatedly washed and filtered in deionized water for 5 times to remove organic impurities. Dry at 60° C. for 12...

Embodiment 2

[0061] Preparation of polytetrafluoroethylene anti-dripping agent B grafted with butyl acrylate and acrylamide

[0062] (1) Treat ultrafine polytetrafluoroethylene powder M530 and sodium-naphthalene treatment solution at a ratio of 1:0.5 for 1 minute, then filter and wash with acetone once to remove excess sodium-naphthalene treatment solution and organic impurities, and then rinse with distilled water Water-soluble impurities were removed once, and activated polytetrafluoroethylene powder was obtained after drying at 10°C.

[0063] (2) 200g of activated polytetrafluoroethylene powder is added to the 2000g ethanol solution of methyl acrylate and acrylamide, wherein the concentration of methyl acrylate is 20wt%, and the concentration of acrylamide is 8wt%. React for 2 hours. After the reaction, the product was first washed once with acetone, then repeatedly washed and filtered five times in deionized water to remove organic impurities. Dry at 20° C. for 5 hours to obtain an a...

Embodiment 3

[0065] Preparation of polytetrafluoroethylene anti-dripping agent C grafted with ethyl acrylate, butyl acrylate and acrylamide

[0066] (1) Treat ultrafine polytetrafluoroethylene powder M530 and sodium-naphthalene treatment liquid according to 1:5 (molar ratio) for 8 minutes, then use acetone suction filtration to wash 3 times to remove excess sodium-naphthalene treatment liquid and organic impurities, Rinse with distilled water for 5 times to remove water-soluble impurities, and dry at 40°C to obtain activated polytetrafluoroethylene powder.

[0067] (2) 200g of activated polytetrafluoroethylene powder is added in the 2000g ethanol solution of methyl acrylate, butyl acrylate and acrylamide, wherein the concentration of methyl acrylate is 10wt%, and the concentration of butyl acrylate is 20wt%, The concentration of acrylamide was 3 wt%, and the reaction was performed at 65°C for 6 hours. After the reaction, the product was first washed with acetone for 3 times, and then repe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com