Elastic energy-dissipation concrete prefabricated wall plate composite connecting piece

A prefabricated wall panel, composite connection technology, applied in the direction of walls, building components, earthquake resistance, etc., to achieve the effect of increasing horizontal pullout strength, high shear strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

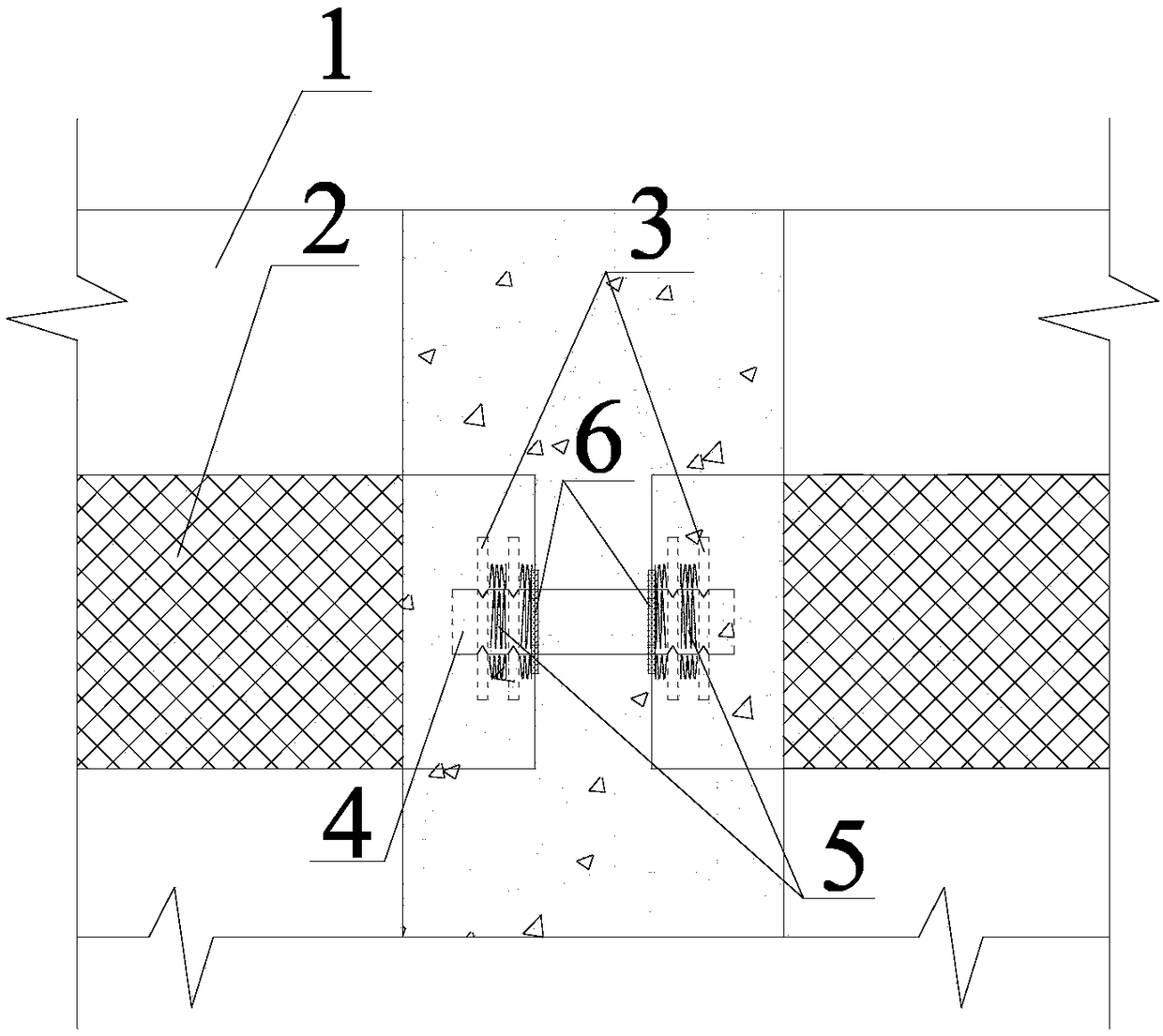

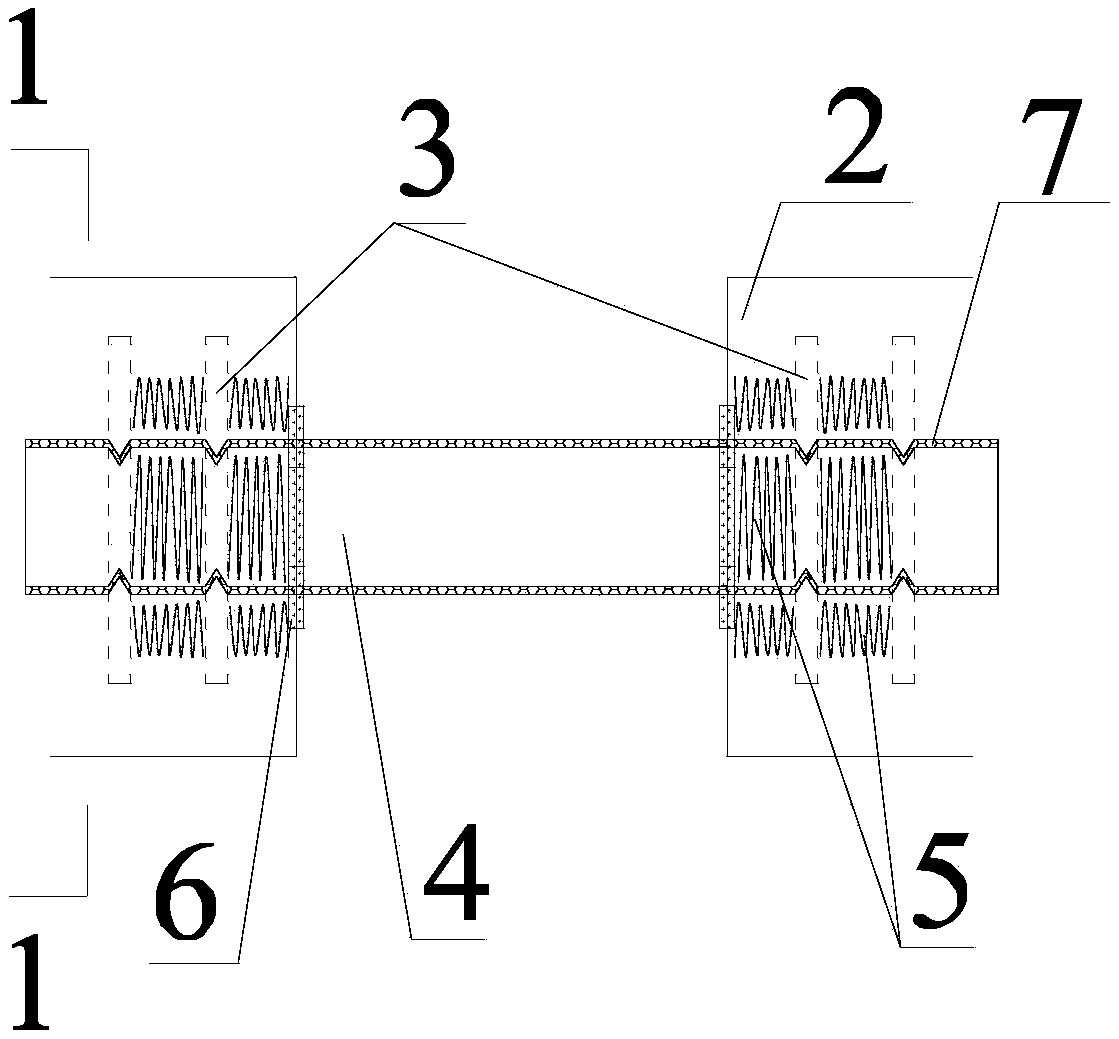

[0034] Such as figure 1 , 2 , 4, 5, 6, and 7 show:

[0035] Step 1: Put FRP composite material sleeves 2 on the two prefabricated concrete wall panels 1 respectively, reserve a round hole 9 on the side of the FRP composite material sleeve 2, and use a certain thickness of elastic material 6 (rubber, polyurethane, etc.) The round hole 9 is bounded (it has certain ductility, and when an earthquake load occurs, it can generate energy consumption and play a protective role);

[0036] Step 2: Paste the concrete prefabricated wall panel 1 and the composite material cover 2 firmly with resin glue;

[0037] Step 3: Insert the hollow steel pipe 4 molded with the FRP material 7 into the round hole 9 (the outer diameter of the composite material screw is 10-20 mm), and leave grooves in the hollow steel pipe 4 (the quantity depends on the situation);

[0038] Step 4: Fix the freely openable circular clip 3 (with a certain degree of elasticity) on the groove of the hollow steel pipe 4 s...

Embodiment 2

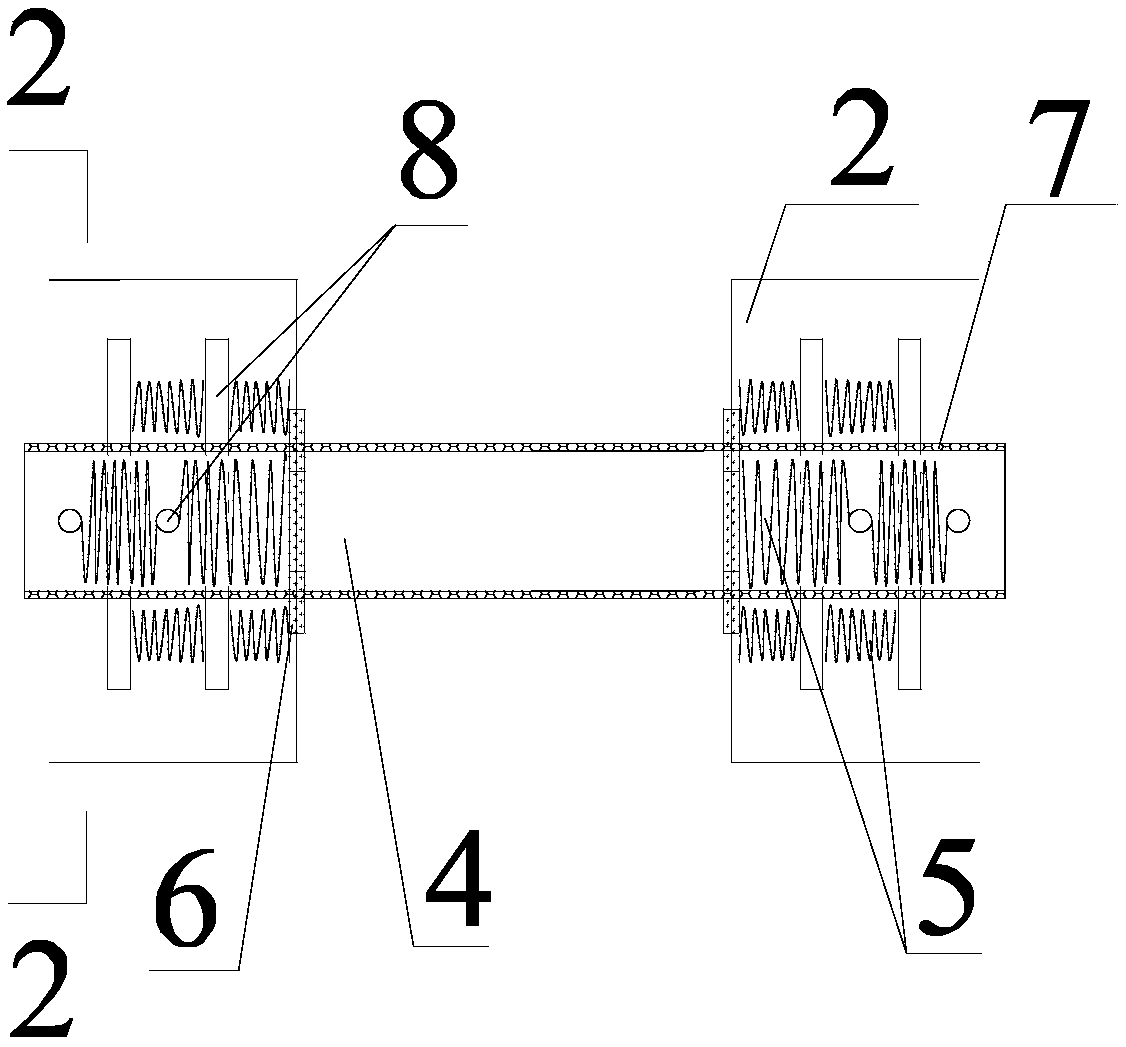

[0041] Such as image 3 , 8 Shown:

[0042] Step 1: Put FRP composite material sleeves 2 on the two prefabricated concrete wall panels 1 respectively, reserve a round hole 9 on the side of the FRP composite material sleeve 2, and use a certain thickness of elastic material 6 (rubber, polyurethane, etc.) The round hole 9 is bounded (it has certain ductility, and when an earthquake load occurs, it can generate energy consumption and play a protective role);

[0043] Step 2: Paste the concrete prefabricated wall panel 1 and the composite material cover 2 firmly with resin glue;

[0044] Step 3: Insert the hollow steel pipe 4 molded into the FRP material into the circular hole 9 (the outer diameter of the composite material screw is 10-20 mm), and drill pin holes on the hollow steel pipe 4 (the number depends on the situation, for Insert pin), the hole diameter is about 5mm, the angle between two pin holes in the same plane is 180°, and the interval between adjacent pin holes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com