Miniature piezoresistive type stress sensor based on tungsten diselenide

A stress sensor, tungsten diselenide technology, applied in the field of MEMS, can solve the problems of tungsten diselenide miniature piezoresistive stress sensor, etc., and achieve the effect of excellent long-term stability

Pending Publication Date: 2019-02-01

TSINGHUA UNIV

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Up to now, there is no relevant report on tungsten diselenide micro piezoresistive stress sensor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0026] The present invention is described below based on examples, but the present invention is not limited to these examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

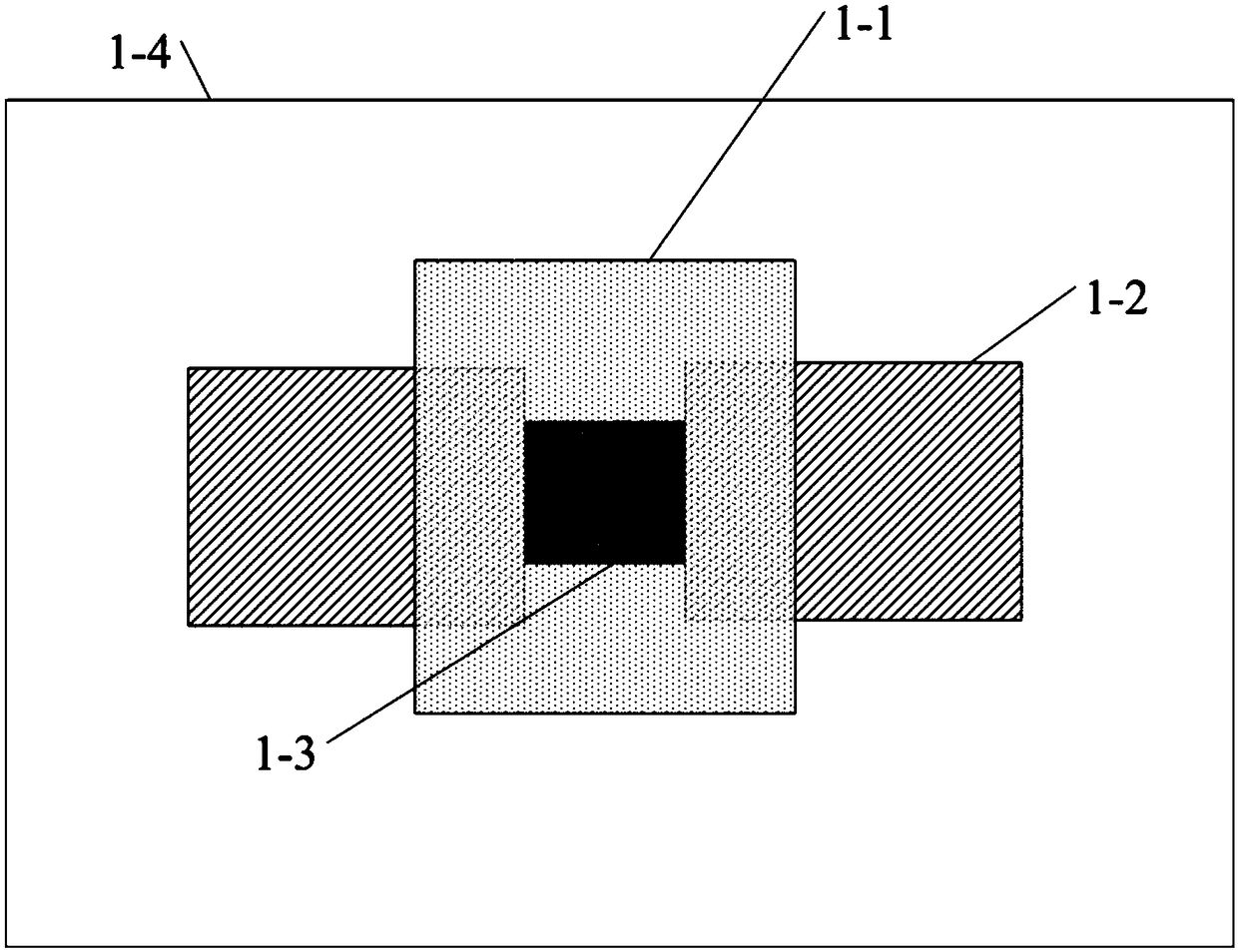

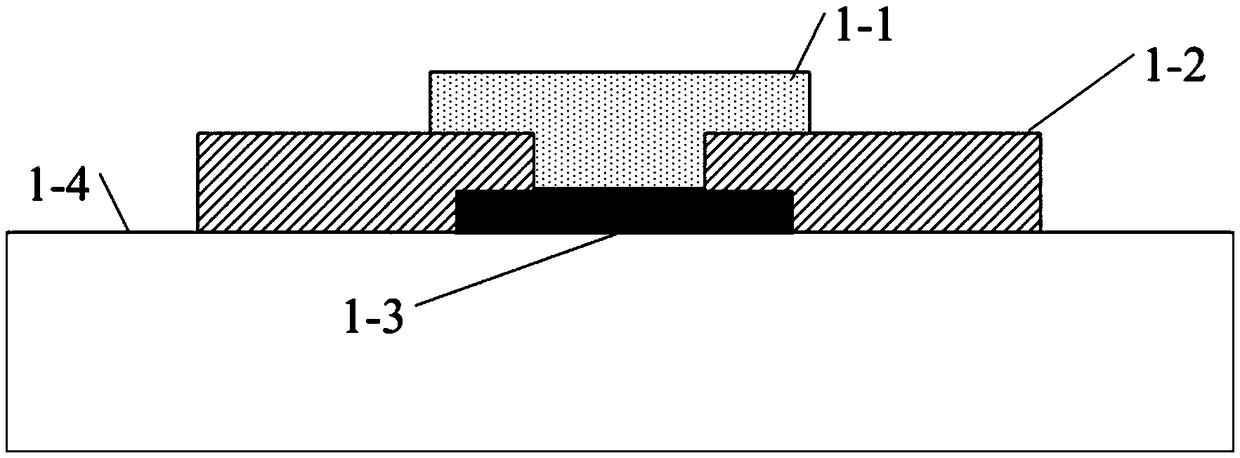

Disclosed is a miniature piezoresistive type stress sensor based on tungsten diselenide. The miniature piezoresistive type stress sensor comprises a boron nitride layer, a metal electrode, a tungstendiselenide layer and a flexible substrate which are arranged in sequence from the top to bottom; the two ends of the tungsten diselenide layer are connected with the metal electrode; the upper surfaceof the tungsten diselenide layer is completely covered with the boron nitride layer; and the tungsten diselenide layer is a two-dimensional material, namely only single-layer atoms or a few layers ofatoms are arranged in the thickness direction, wherein the number of a few layers is 1-10. According to the miniature piezoresistive type stress sensor, tungsten diselenide is used as a core sensitive material, and stress detection is performed based on the characteristic (the piezoresistive property) that tungsten diselenide is sensitive to stress; and boron nitride is used as a protection layer, so that the stress sensor has the characteristics of high bending resistance, relatively high measuring range, high sensitivity, small size, easy processing, high long-term stability and the like.

Description

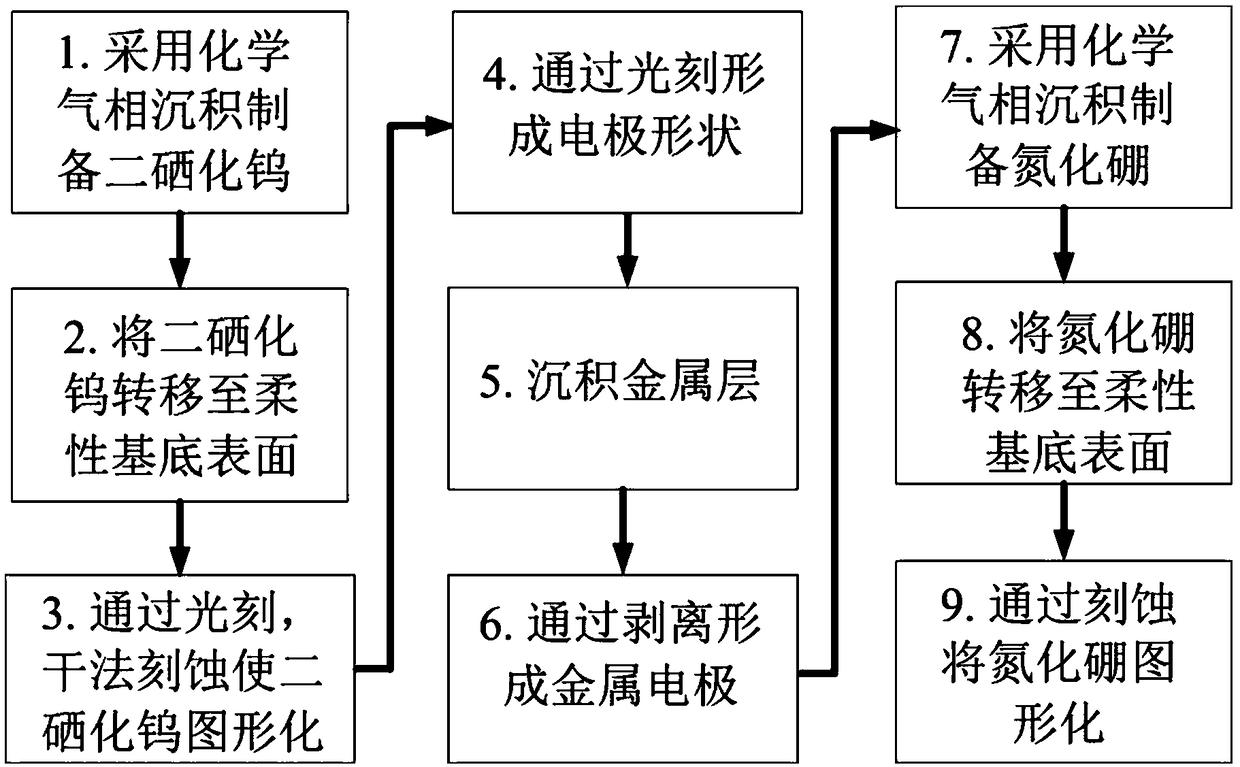

technical field [0001] The invention relates to the technical field of MEMS, in particular to a micro piezoresistive stress sensor based on tungsten diselenide, which adopts tungsten diselenide as a core sensitive material, and utilizes its piezoresistive characteristics for stress detection. Background technique [0002] Traditional piezoresistive stress sensors usually use metal or silicon as the core sensitive material. The piezoresistive effect of metal materials mainly depends on the change of their own geometric dimensions, so the gauge factor is very small and the sensitivity is poor; the gauge factor of silicon is much larger than that of metal, but the fracture strain is small, and it is prone to fracture under large deformation, so the stress range that can be measured smaller. [0003] With the development of microelectronics technology, more and more micro piezoresistive stress sensors based on microelectromechanical systems (MEMS) are gradually developed. It h...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01L1/18

CPCG01L1/18

Inventor 李鹏耿策洋

Owner TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com