Full-automatic breathability tester

A breathable, fully automatic technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of long time consumption and low test efficiency, and achieve the effects of easy operation, convenient and fast position adjustment, and stable operation of the connecting rod.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

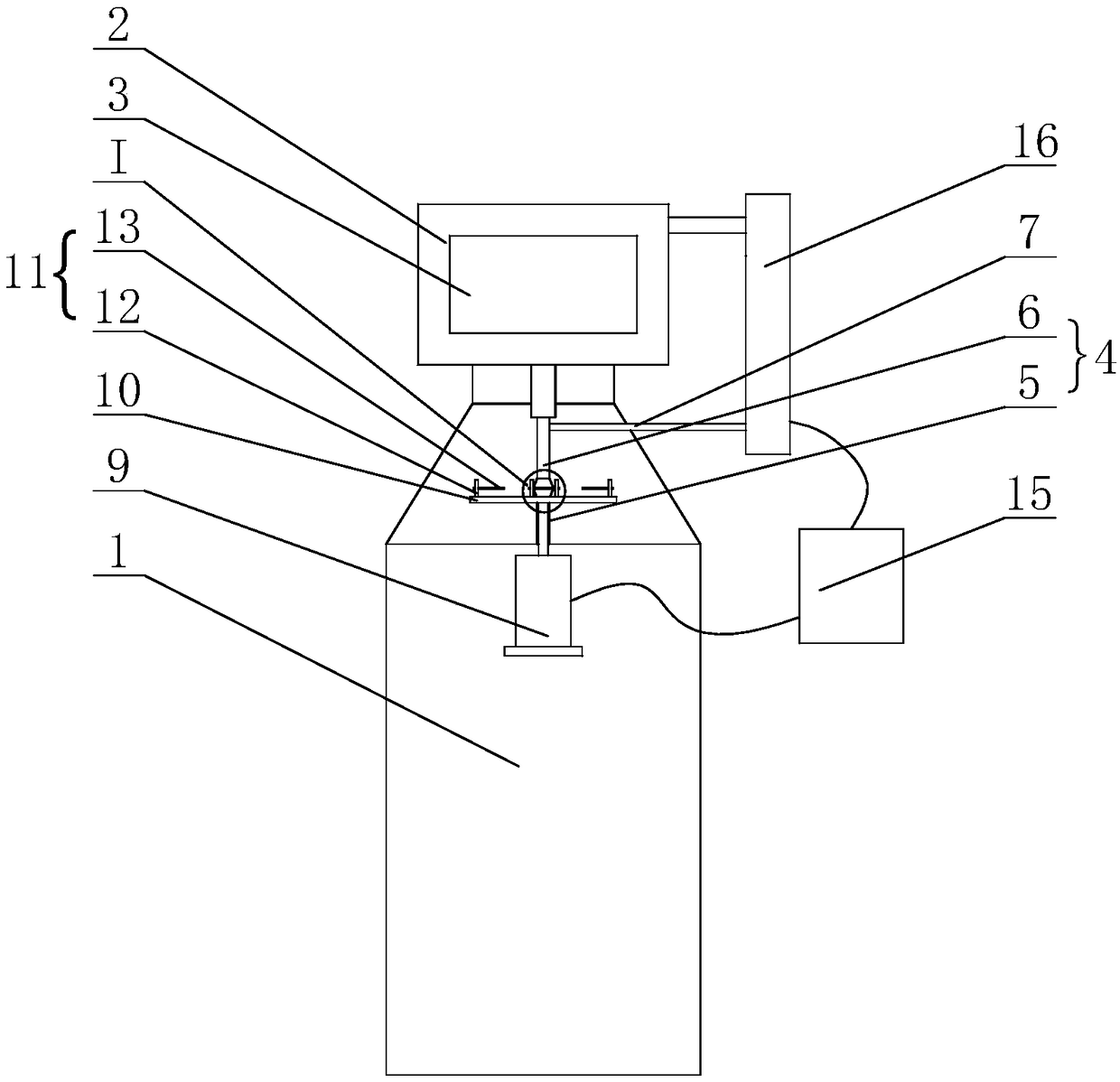

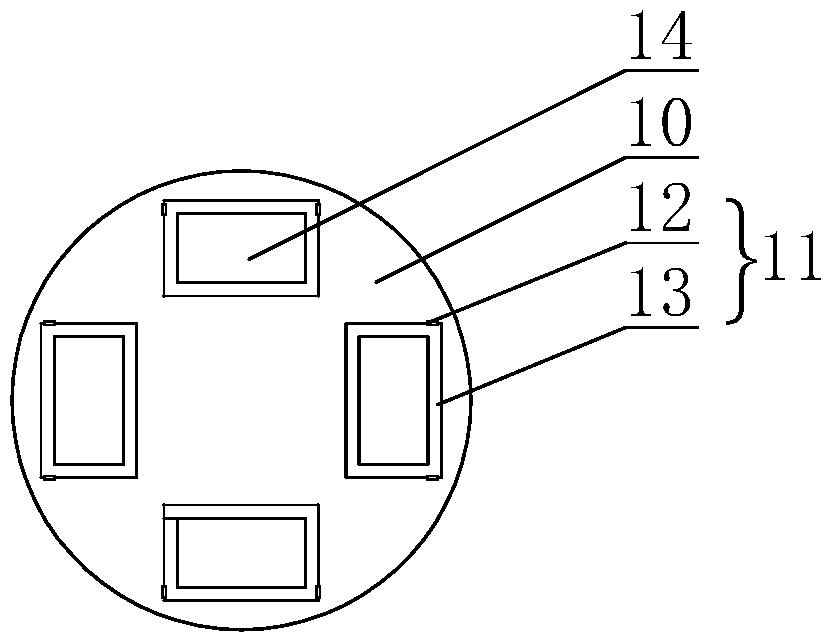

[0041] The fully automatic gas permeability tester comprises a frame 1, the frame 1 is provided with a machine head 2, a pressure sensor, a CPU data processor and a suction fan are arranged in the said machine head 2, and the front end of the machine head 2 is provided with Display control panel 3, the lower end of the machine head 2 is provided with a test device 4 and an airflow flow measurement sensor, the test device 4 includes a lower test chamber 5 and an upper test chamber 6, and the lower test chamber 5 is fixedly connected to the frame 1 , the bottom of the machine head 2 is provided with a fixed pipe, the top of the upper test chamber 6 is located in the fixed pipe, the upper test chamber 6 is slidingly connected with the fixed pipe, and a sliding rod 7 is arranged on one side of the upper test chamber 6, so The end of the sliding rod 7 away from the upper test chamber 6 is provided with an upper test chamber adjustment device 8; the frame 1 is provided with a first m...

Embodiment 2

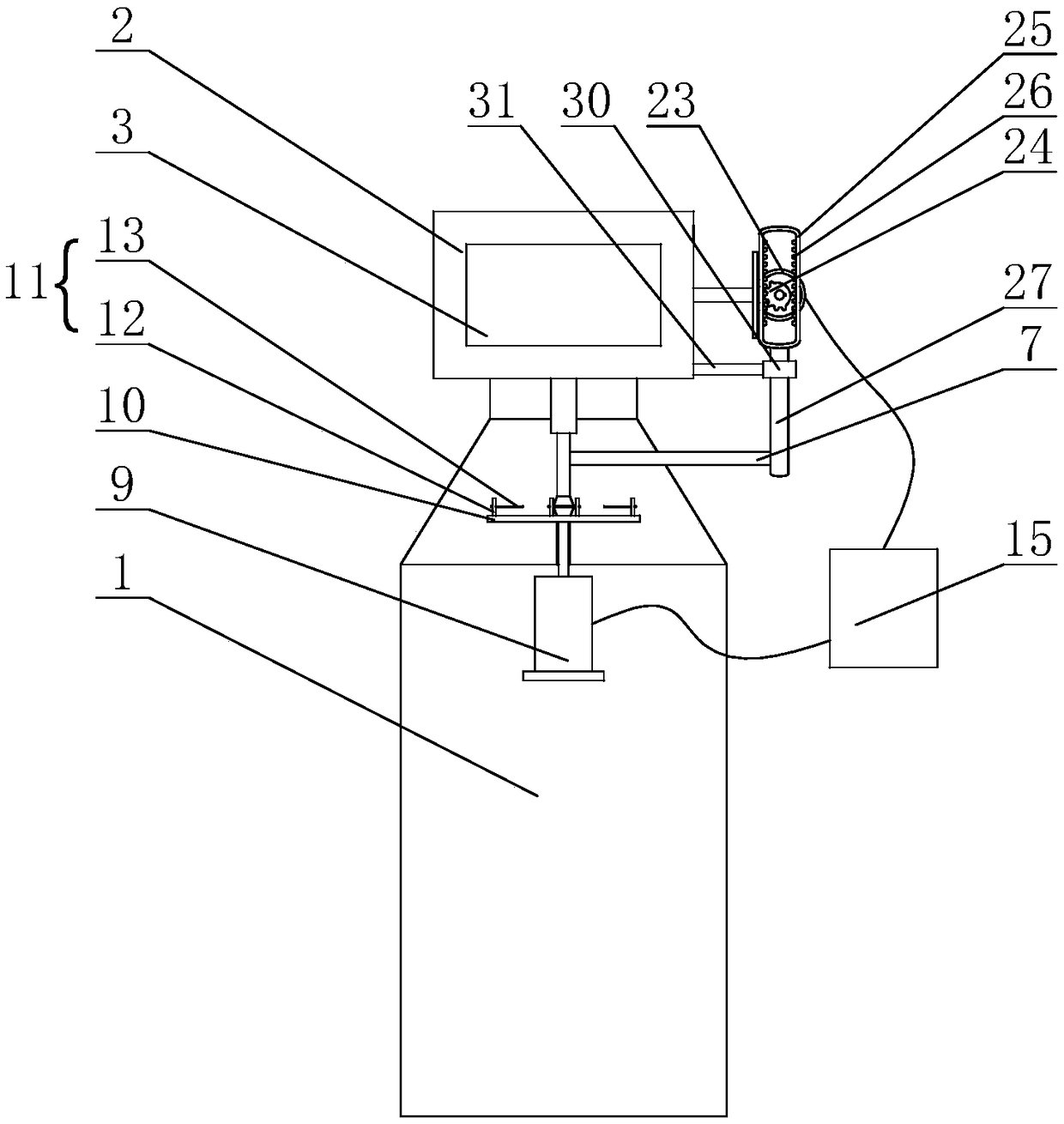

[0043] In this embodiment, the upper test chamber adjustment device 8 includes a third motor 23, the third motor 23 is fixedly connected with the machine head 2, and a residual gear 24 is arranged on the output shaft of the third motor 23, and the residual gear 24 is arranged on the output shaft of the third motor 23. A support frame 2513 is arranged on one side of the gear 24, and a rack 26 is arranged in the support frame 2513. There are two racks 26, and the two racks 26 are located on both sides of the residual gear 24. The gear 24 is compatible, the rack 26 is fixedly connected to the inner wall of the support frame 2513, the bottom of the support frame 2513 is provided with a connecting rod 27, and the end of the sliding rod 7 away from the upper test chamber 6 is fixedly connected to the connecting rod 27. The position of the upper test chamber is adjusted by the residual gear and rack structure, and the automatic reciprocating motion of the upper test chamber can be rea...

Embodiment 3

[0045] In this embodiment, the upper test chamber adjustment device uses a ball screw structure to drive the sliding rod to slide, and the motor uses Yaskawa SGM7J-06A servo motor to perform forward and reverse rotation of the screw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com