Hybrid Position Observer and Position Sensorless Servo System for Permanent Magnet Synchronous Motor

A technology of permanent magnet synchronous motor and mixed position, which is applied in the direction of control system, control generator, vector control system, etc., and can solve problems such as lack of technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

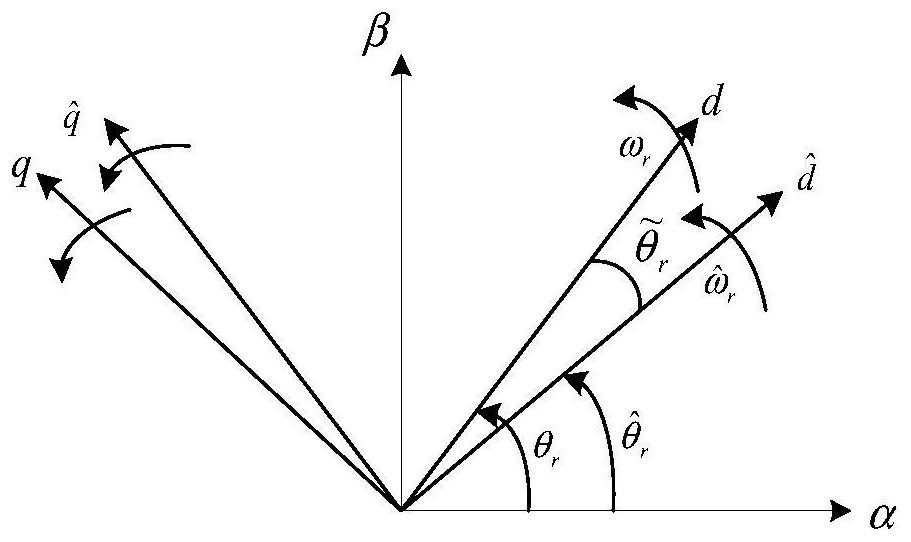

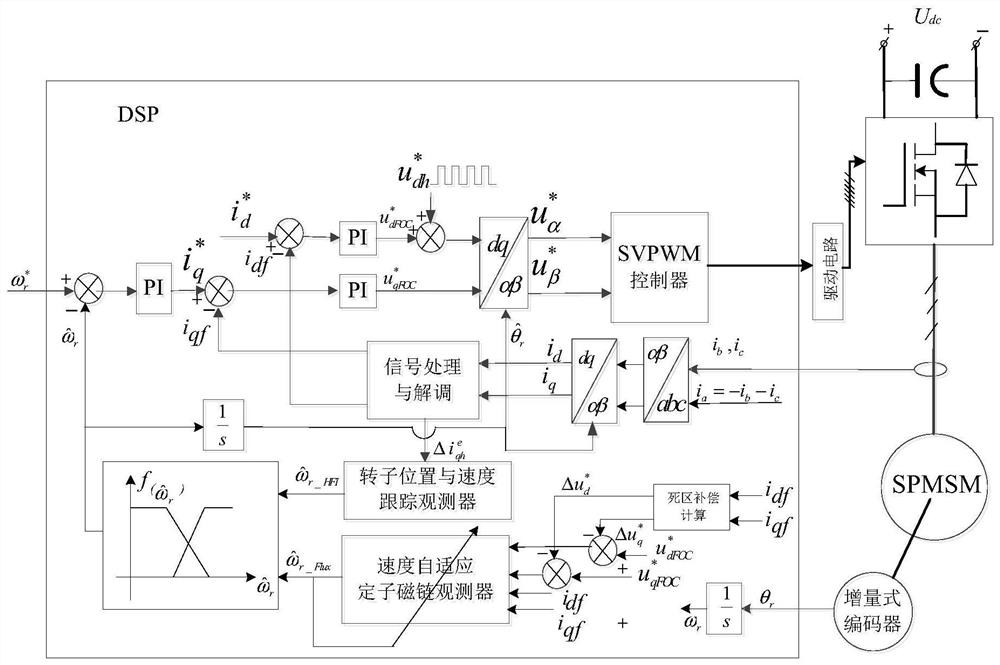

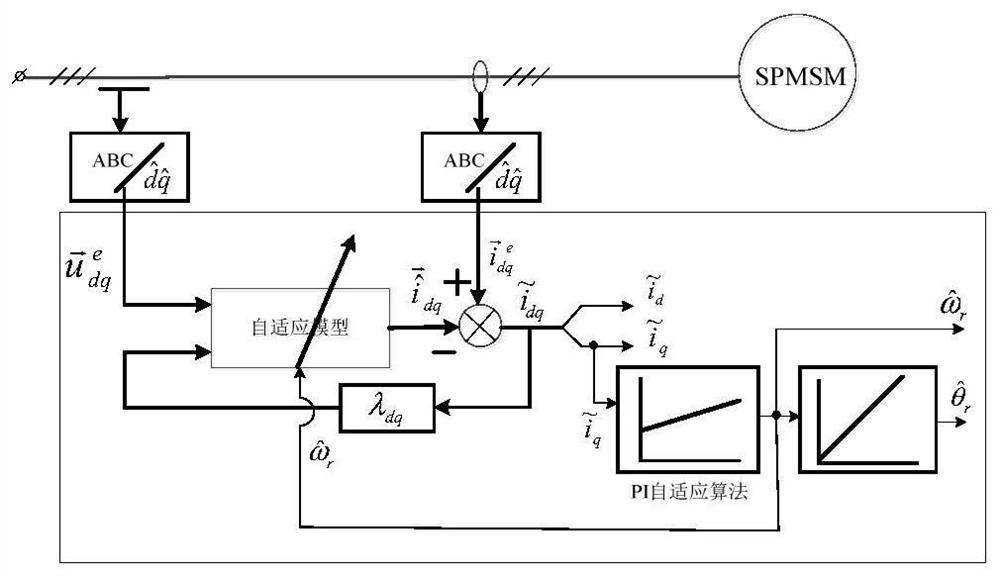

[0096] As introduced in the background technology, in the prior art, there is a smooth transition between the estimated value of rotor position angle and rotational speed estimated by the HFI scheme in the zero and low speed regions and the stator observer scheme in the middle and high speed regions. This scheme estimates the lack of out-of-step when the speed difference is large. The speed-adaptive stator flux observer needs the actual stator voltage information. Considering the cost and the measurement difficulty of the pulse voltage generated by PWM modulation, the voltage Most of them are replaced by the output of the current loop regulator, and there are certain differences between the two due to factors such as the dead zone of the inverter and the turn-on voltage drop of the inverter switching device, which affects the estimation accuracy of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com