Electronic chip efficient welding equipment

A technology for electronic chips and welding equipment, which is applied in the field of high-efficiency welding equipment for electronic chips, can solve the problems of inconvenient adjustment of the rotation angle of the rotary servo motor, failure of the rotary servo motor, and large size of the welding frame, and achieve good shock absorption and buffering effects. The effect of reducing the volume of the equipment and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

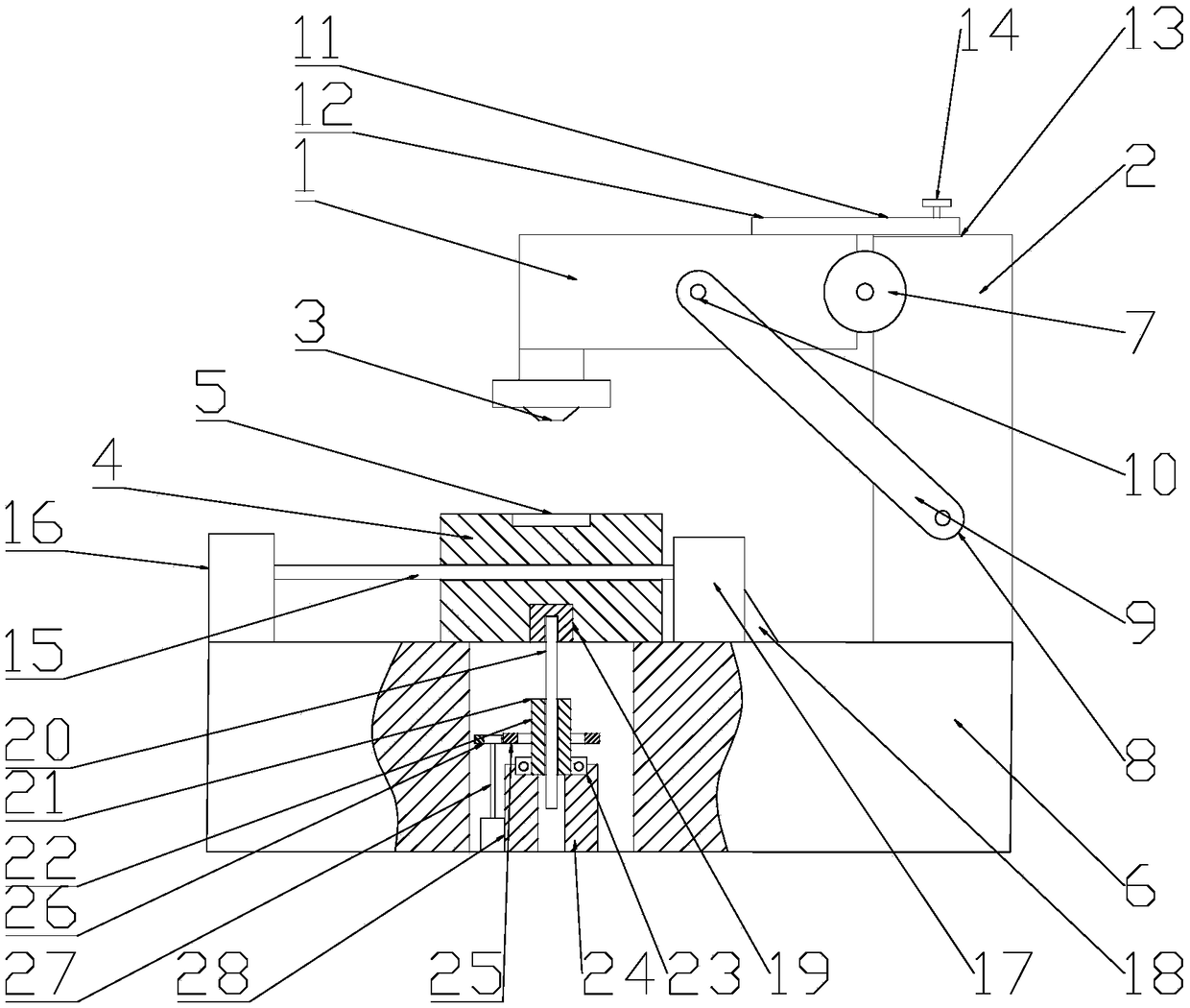

[0016] see figure 1 , a high-efficiency welding equipment for electronic chips, including a welding frame 1, a column 2, a welding head 3, a welding table 4, an electronic chip 5 and a base 6, the column 2 is fixed on the right side of the upper end surface of the base 6 by bolts, and the The welding frame 1 is arranged on the left side of the top of the column 2, the welding head 3 is installed on the left side of the bottom of the welding frame 1, the welding table 4 is arranged directly below the welding head 3, and the welding The electronic chip 5 is arranged on the platform 4, and the welding platform 4 is placed on the base 6; the welding frame 1 is installed on the left side of the top of the column 2 through the rotating shaft 7, and the column 2 is symmetrical front and back The bolt is fixed with hinge A8, and the front and rear symmetrical bolts of the welding frame 1 are fixed with hinge B10. Freely rotate on the column 2 and maintain good stability; the welding ...

Embodiment 2

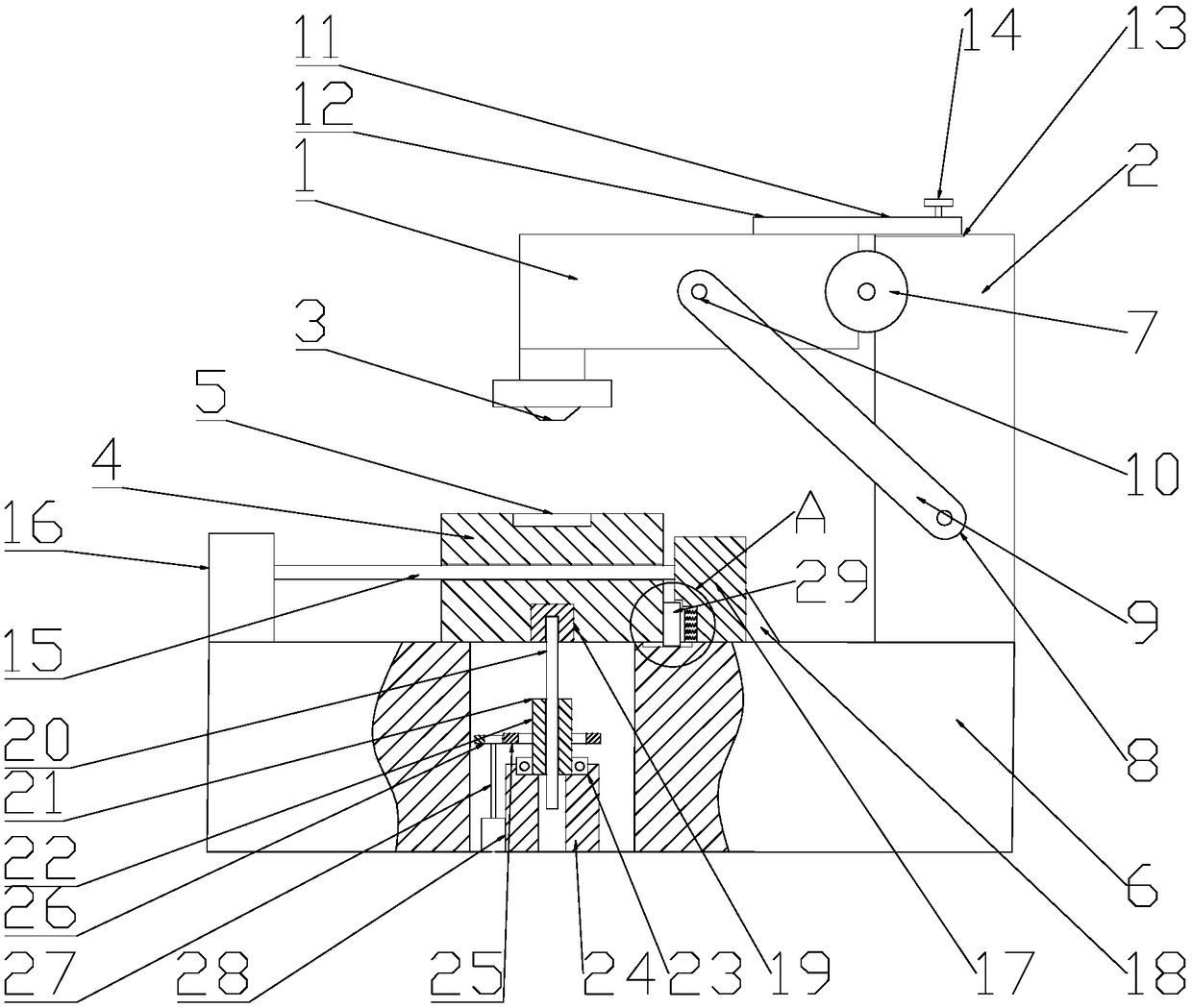

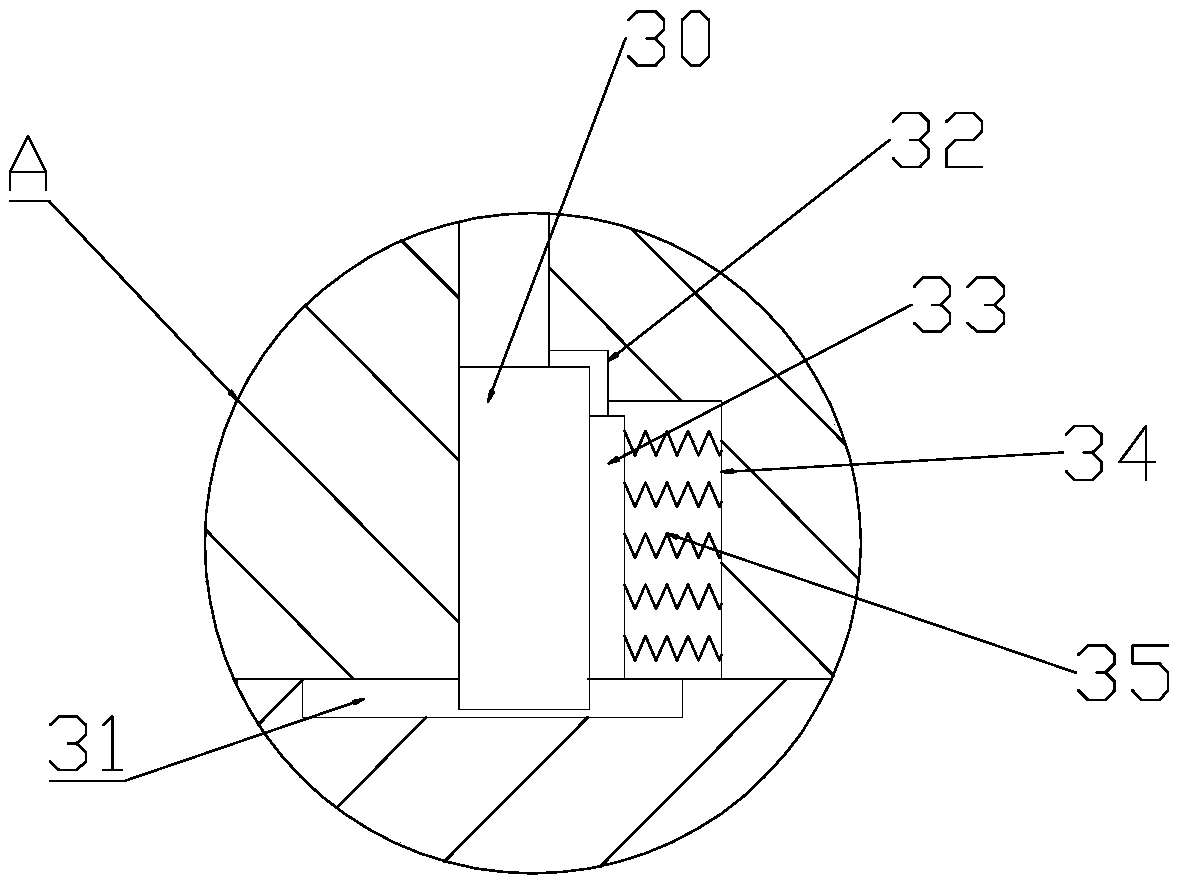

[0018] see figure 2 and image 3 Compared with Embodiment 1, this Embodiment 2 differs only in that a buffer mechanism 29 is provided on the left side of the baffle plate 17, which can have a good shock-absorbing and buffering effect, and avoid contact with the welding table 4 during the sliding process. The impact of the baffle plate 17 causes the reduction of the accuracy of the whole device; the buffer mechanism 29 includes a limiting plate 30, a chute 31, a limiting groove 32, a buffer plate 33, a cavity 34 and a spring 35, and the limiting plate 30 is in contact with the limiting plate 30. The right end surface of the welding table 4 is in close contact, the limiting plate 30 is slidably installed in the limiting groove 32 through the chute 31, a buffer plate 33 is welded and fixed on the right side of the limiting plate 30, the buffering Plate 33 is slidably mounted in said cavity 34 via said spring 35 .

[0019]The working principle of the present invention is: descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com