Wooden board cutting device

A cutting device and wood board technology, applied in the field of wood processing, can solve the problems of up and down vibration of wood boards, unfavorable board feeding, and low cutting quality, and achieve the effects of reducing up and down vibration, improving cutting quality, and facilitating transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

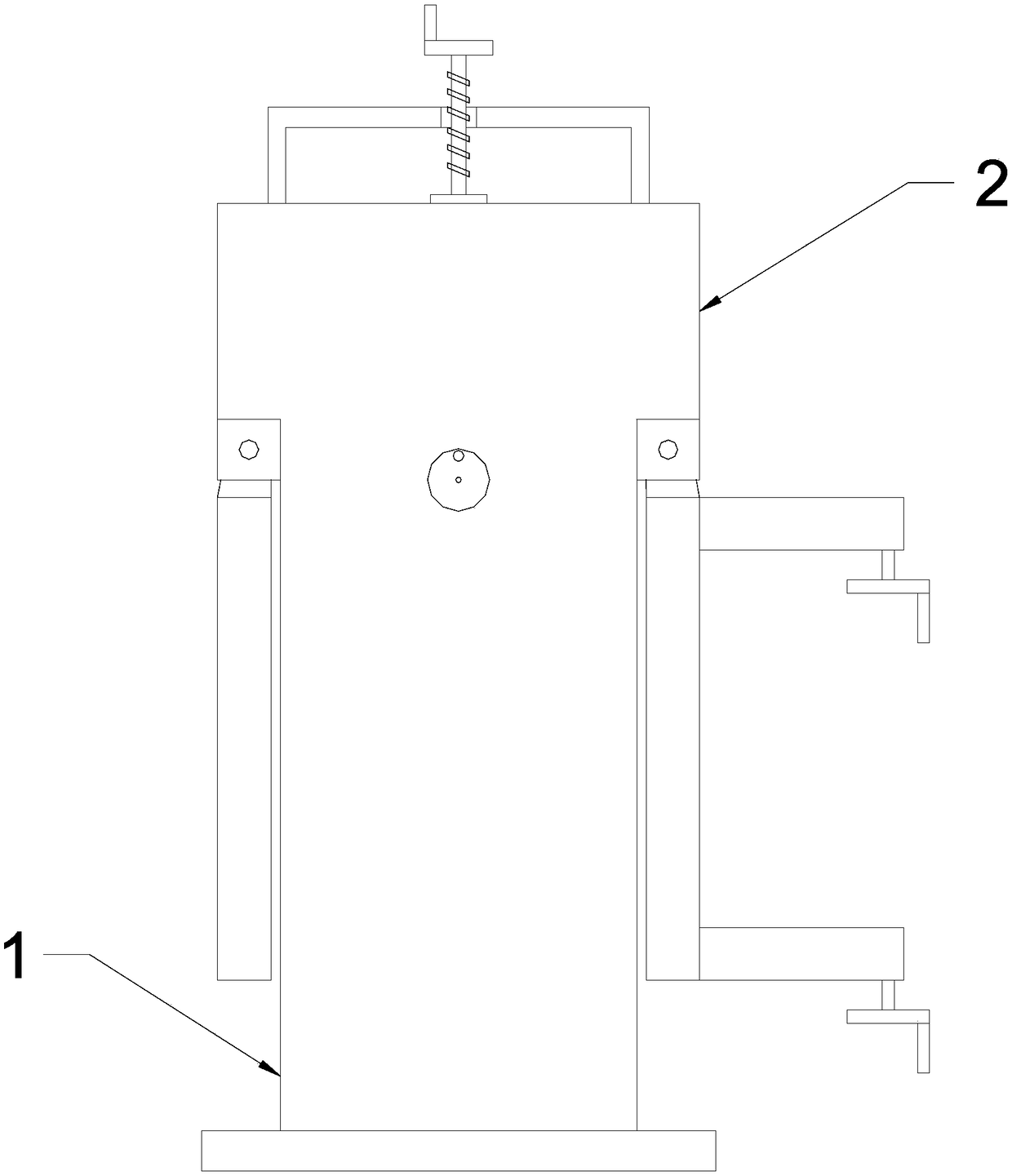

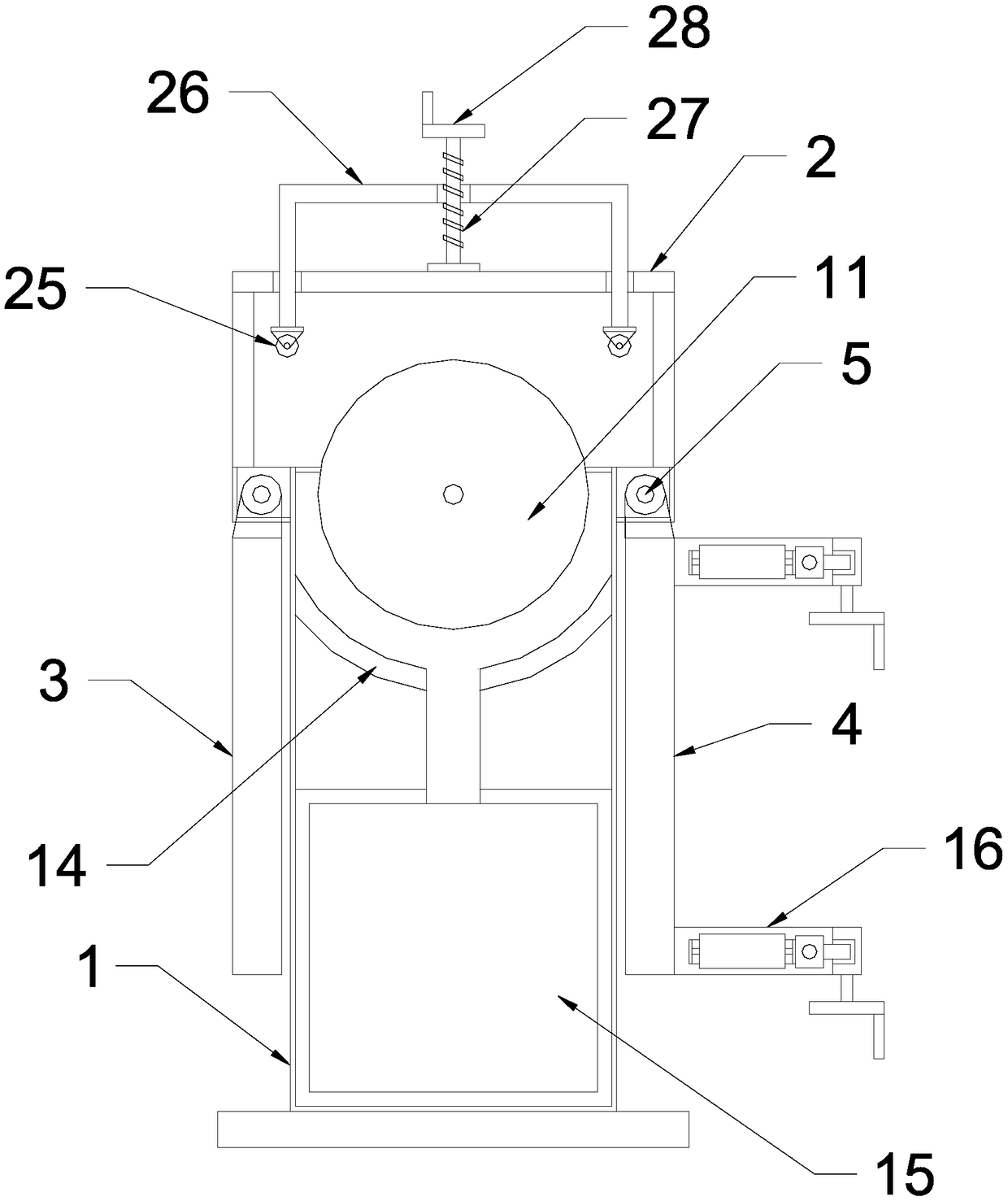

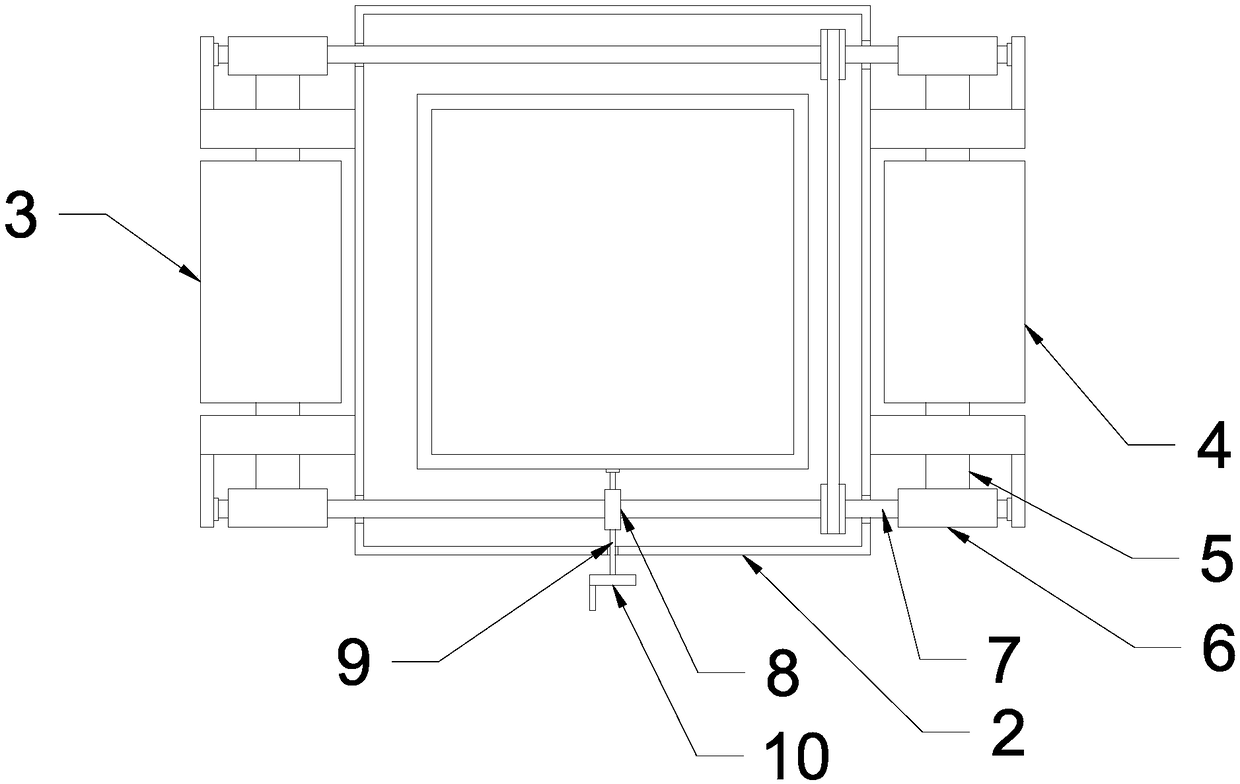

[0023] see Figure 1~5 , in an embodiment of the present invention, a wood cutting device includes a housing 1 and a cutting wheel 11; the housing 1 is a hollow box structure with a slit on the upper end surface, and a cutting wheel 11 is arranged in the slit, The cutting wheel 11 is rotationally connected with the housing 1 through a rotating shaft. The rotating shaft of the cutting wheel 11 extends to the rear side of the housing 1 and is connected to the output shaft of the cutting motor 13 through the first transmission belt 12. The cutting motor 13 is electrically connected to an external power supply. Drive the cutting wheel 11 to rotate and cut the plank;

[0024] The outer side of the cutting wheel 11 is provided with a protective cover 2, the protective cover 2 is a hollow box structure with openings at both ends, the left extension plate 3 and the right extension plate 4 are respectively arranged on both sides of the protective cover 2, the left extension plate 3 and...

Embodiment 2

[0028] see figure 2 The difference between this embodiment and Embodiment 1 is that abutment rollers 25 are provided on both sides of the cutting wheel 11, and the abutment rollers 25 are rotatably connected to a lifting frame 26, and the lifting frame 26 penetrates the protective cover 2 and slides with the protective cover 2 Connection, lifting frame 26 runs through screw rod 27, screw rod 27 is connected with protective cover 2 in rotation, the top of screw rod 27 is fixedly connected with the third rotating handle 28, rotates the third rotating handle 28, drives screw rod 27 to rotate, and then drives lifting The frame 26 drives the abutment roller 25 to move up and down, and squeezes and fixes planks of different thicknesses, so as to ensure the stability of the planks when they move laterally and cut, reduce the longitudinal vibration during plank cutting, and improve the cutting quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com