Fiber slurry synchronous-adsorption molding lamination composite forming process method and forming machine thereof

A molding process and molding machine technology, applied in textiles and papermaking, etc., can solve the problems that a set of equipment cannot meet the conversion and manufacturing needs of products with different performances, the high cost of product conversion design, and the complexity of the molding process, etc., to shorten the design cycle, The effect of reducing the design cost and reducing the difficulty of deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

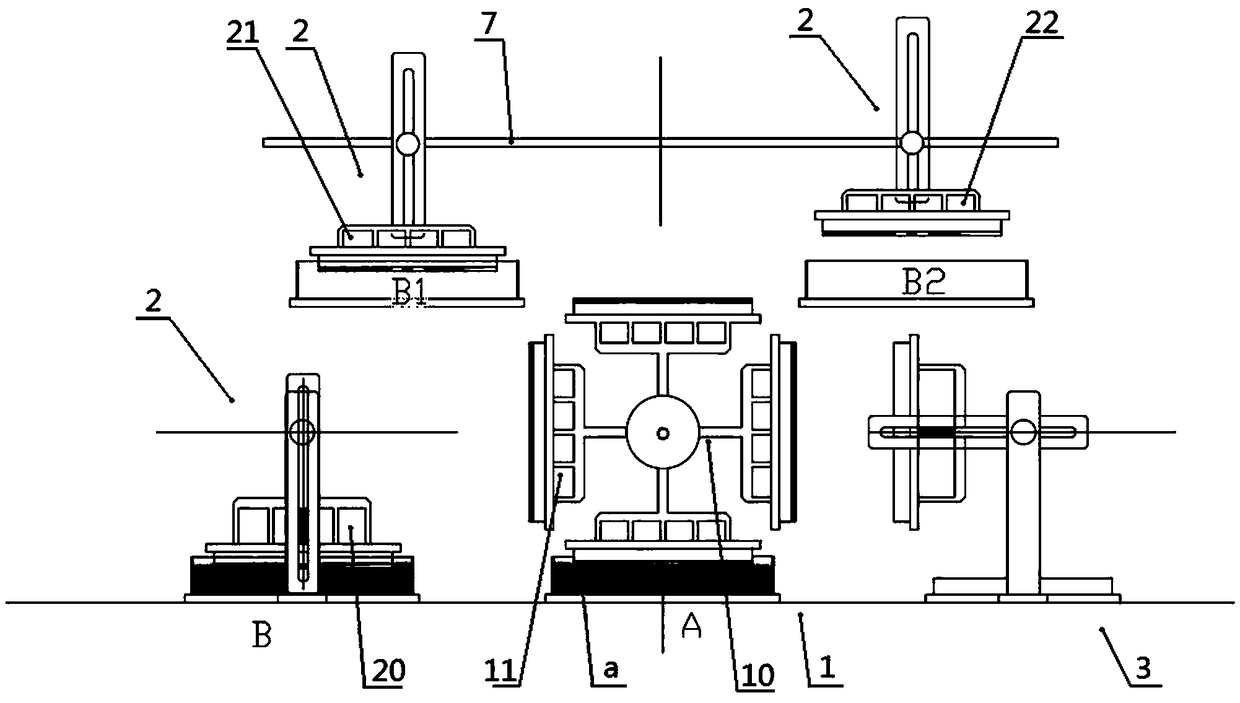

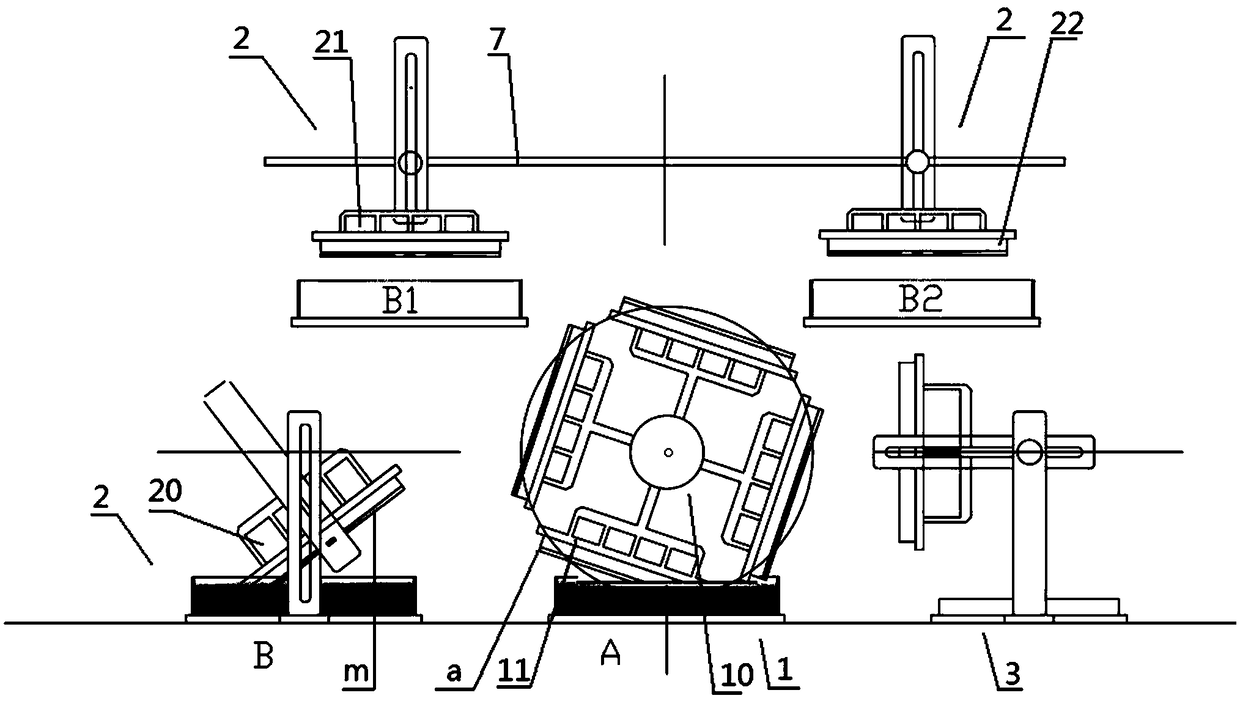

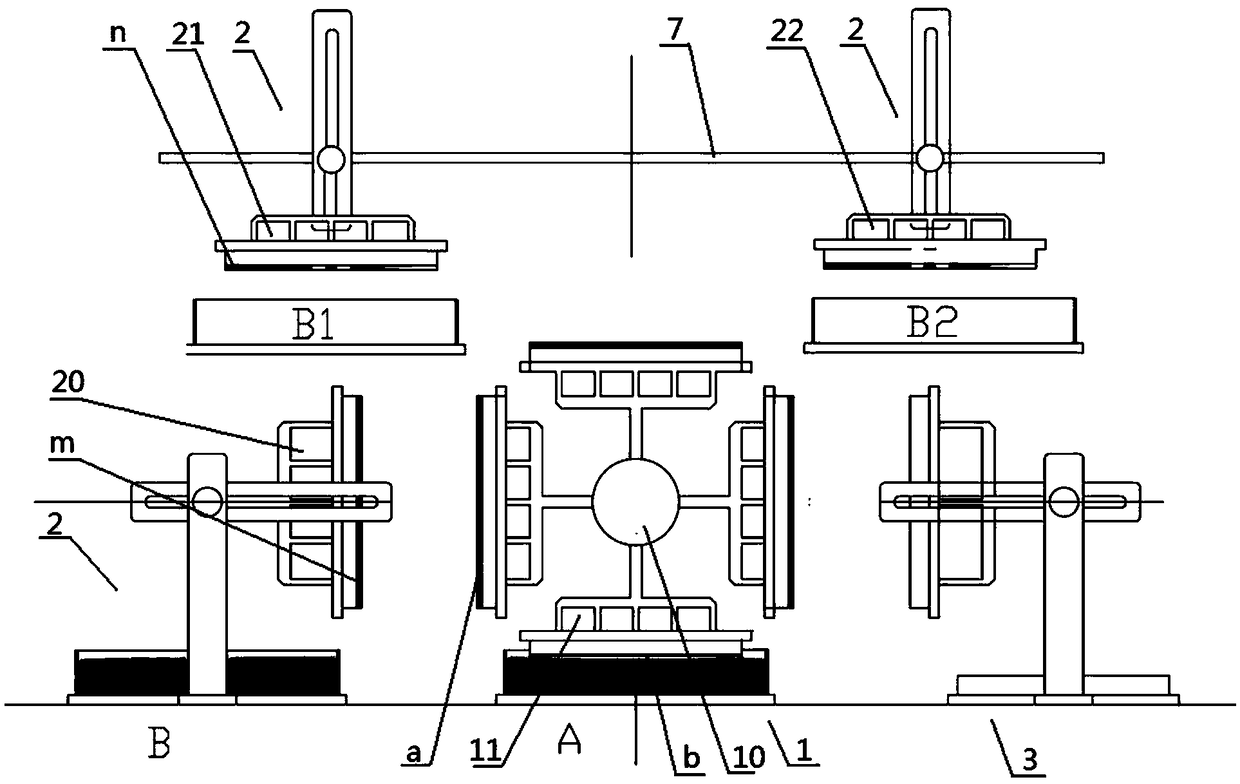

[0011] This patent application will describe the technical solution of this patent application in detail through the following contents.

[0012] The molding machine of the fiber pulp synchronous adsorption molding laminated composite molding process method of the present application realizes the continuous and orderly completion of the fiber pulp synchronous adsorption molding laminated composite molding process method of multi-fiber pulp molding layer superimposed composite molding process, and the manufacturing efficiency is high. High, easy to make pulp molding products meet the requirements of diversified technical performance indicators, overcome the single-layer molding process method, and the long production line that exists in the production line direction, each molding layer is gradually superimposed into the slurry adsorption in chronological order , Restricted process conditions, complex equipment and processes, low efficiency, difficult to quickly adjust to meet th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com