Preparation method of semiconductor probe tip sample for detection of three-dimensional atom probe

An atomic probe and semiconductor technology, applied in the field of micro-nano-scale material sample preparation, can solve problems such as data distortion and large differences in element evaporation fields, so as to improve efficiency, reduce sampling steps, and reduce the possibility of needle tip sample breakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

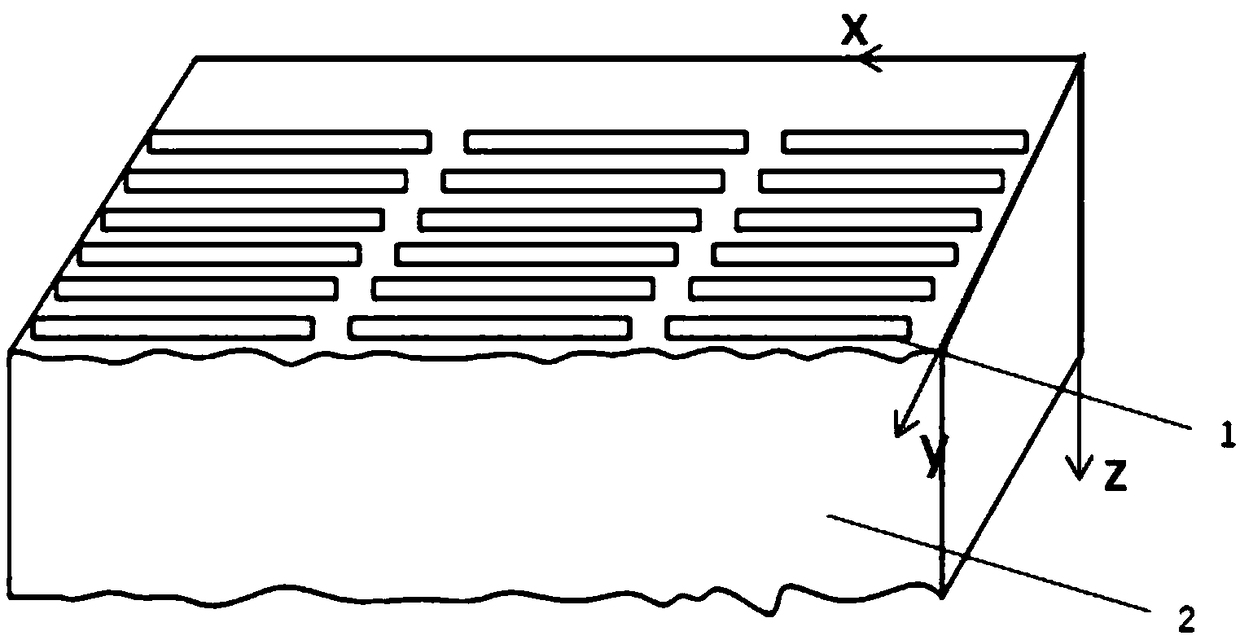

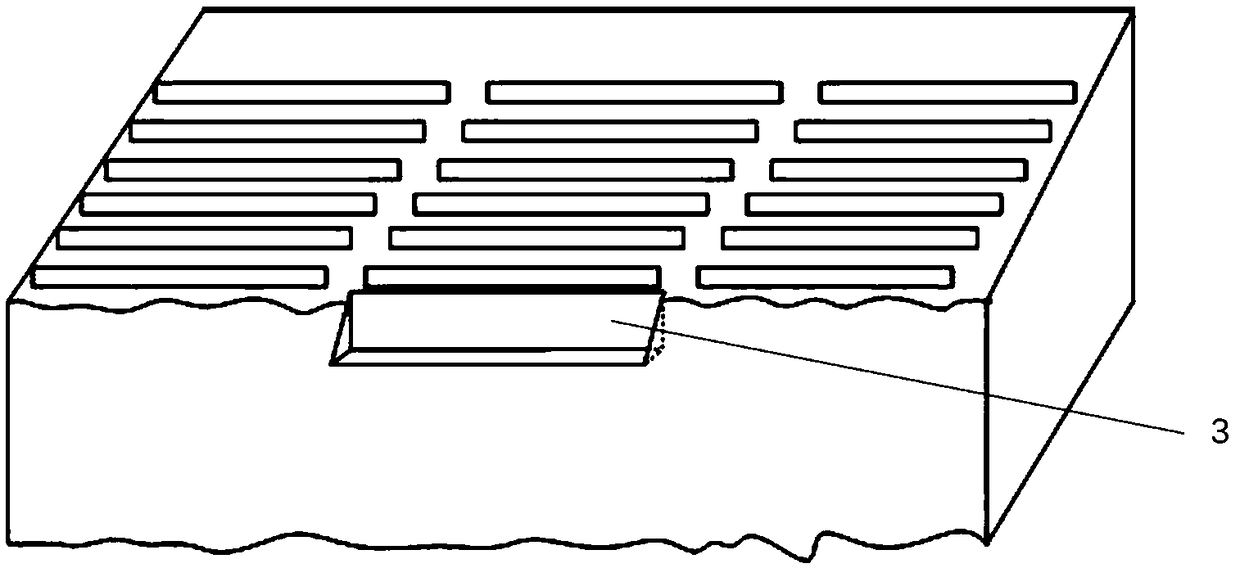

[0042] By using the fin structure sample processing technology in the cross-cut fin field effect transistor of the present invention, the fin structure of the fin field effect transistor can be prepared for three-dimensional atom probe tip samples. This method is different from the traditional method of vertically placing the entire fin structure on a needle tip, but adopts a segmented method, cross-cutting the fin structure in the semiconductor device, and placing the fin structure in the semiconductor device perpendicular to the growth direction. Use the focused ion beam to cut into a small section, that is, only a small section of the fin structure is included in each 3D atom probe tip sample, and then cut multiple needle tips, and after collecting the 3D atom probe data for all the tip, that is Can be combined to form a complete fin structure.

[0043] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com