Non-isolated bidirectional DC/DC converter with high step-up ratio

A high boost ratio, converter technology, used in output power conversion devices, DC power input to DC power output, instruments and other directions, can solve the overall efficiency limit, reduce converter efficiency, low-voltage side current problems such as large , to achieve the effect of clear circuit structure, easy expansion, and high boost ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

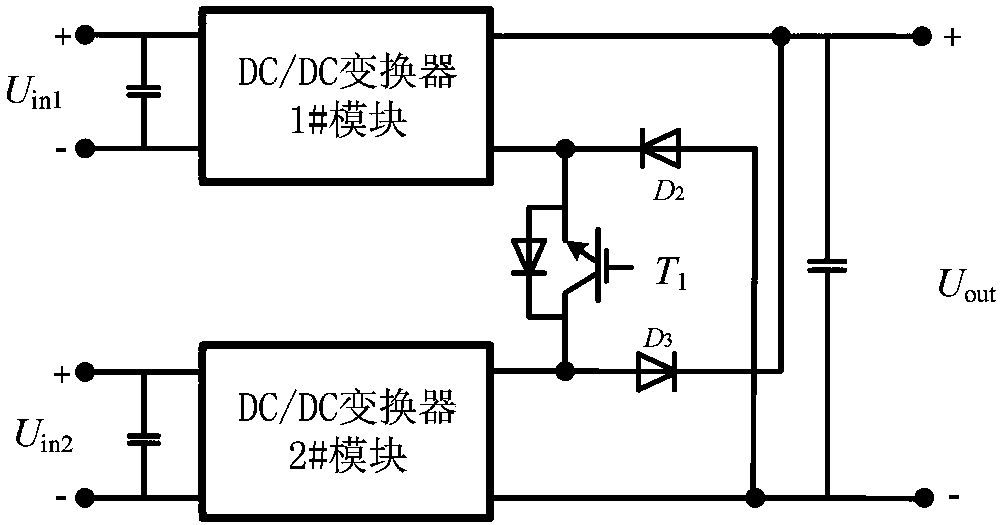

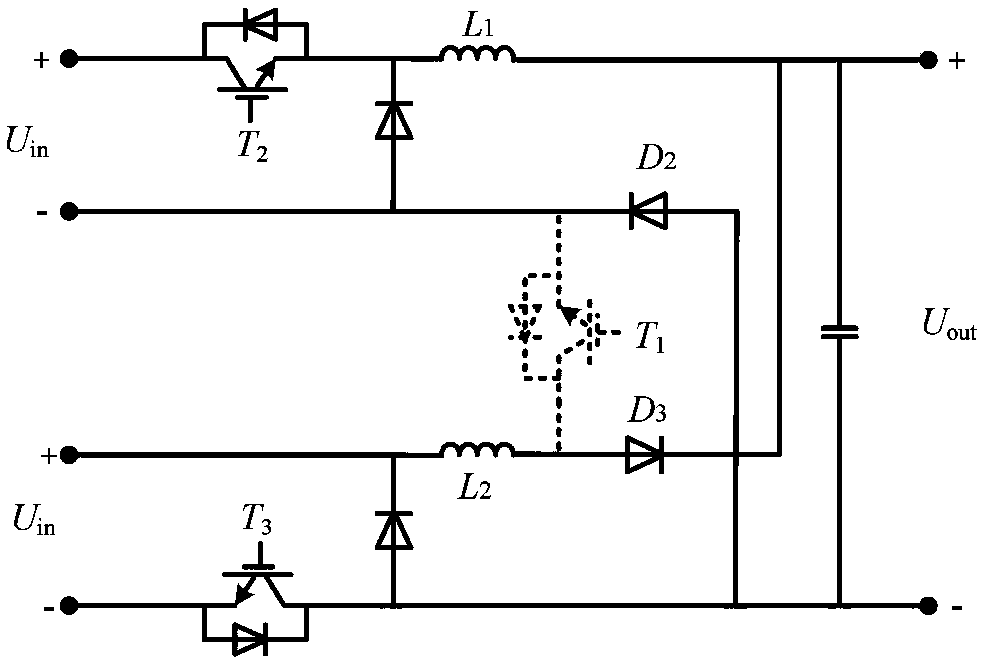

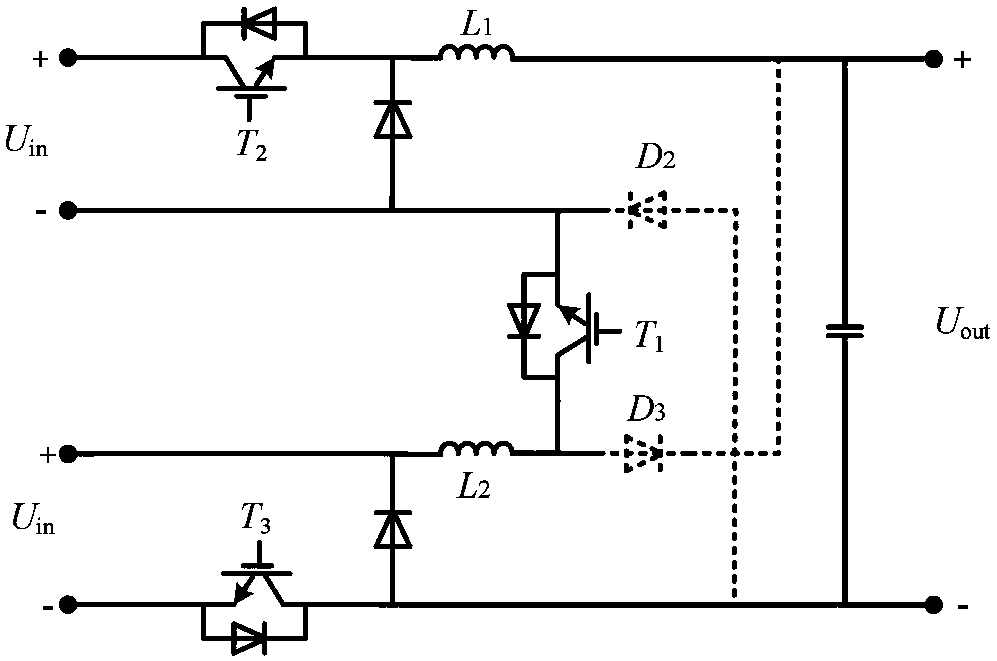

[0020] A non-isolated bidirectional DC / DC converter with a high step-up ratio. The converter has a multi-module input parallel connection and output series topology. The inductor current of each module is the same, and the actual processing power of each stage is also the same. The total output voltage of the converter is the sum of the output voltage and the input voltage of all modules, and the overall boosted voltage is distributed to each module, so the boost ratio that needs to be achieved by a single module is reduced. This structure effectively improves the converter overall efficiency. When the gap between the output voltage and the input voltage is large, the output voltage to be borne by each module becomes higher, but the input parallel structure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com