Compartment grid plate of large-volume low-energy continuous ball mill for ceramic industry

A technology of continuous ball milling in the ceramic industry, applied in the field of compartment grate plates, which can solve problems such as non-conformity to continuous, high-efficiency production, poor effect of grate plate screening for slurry, easy clogging of grate plates, etc., and achieve good wear resistance and durability, grinding Full, high-intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

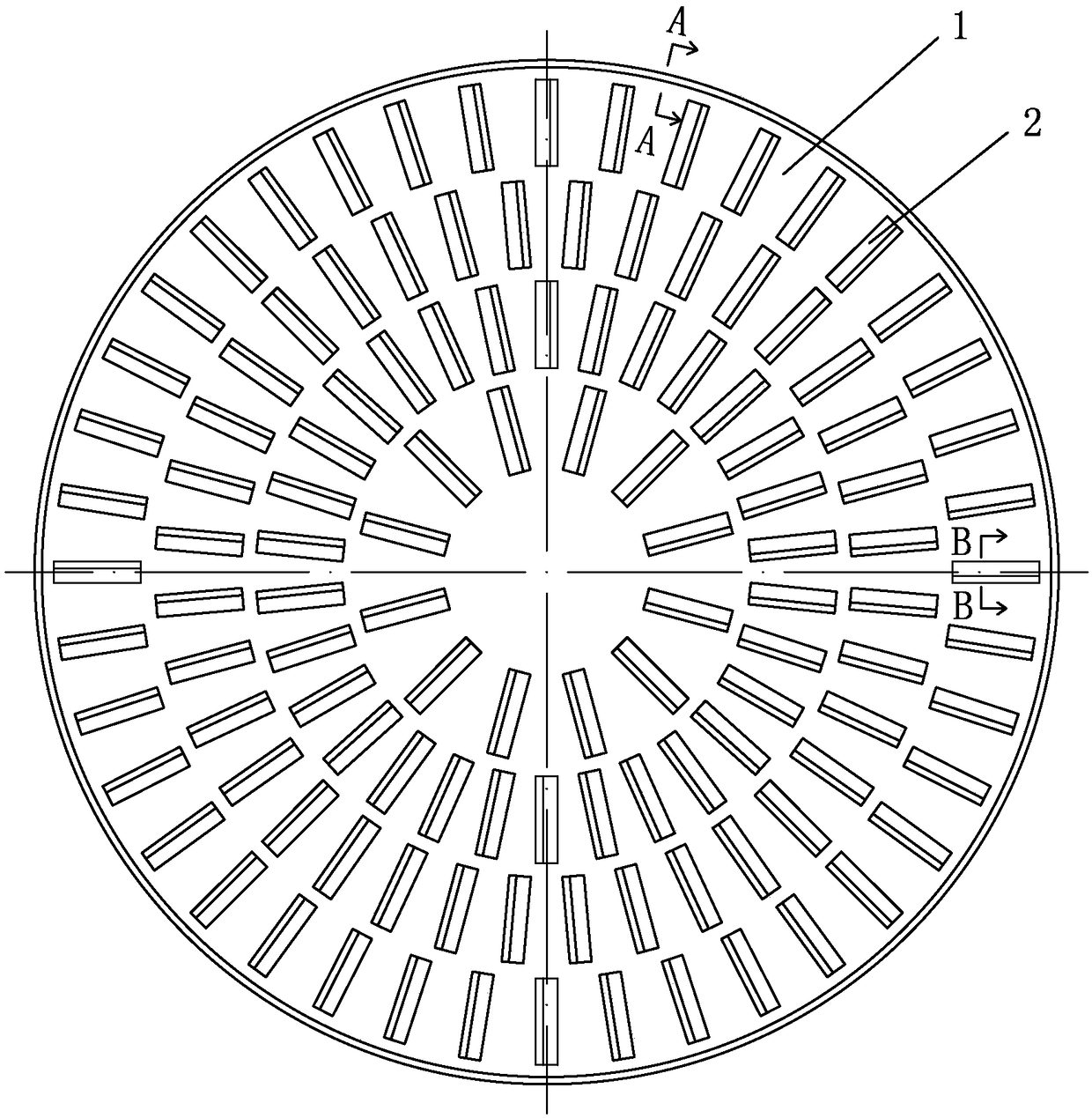

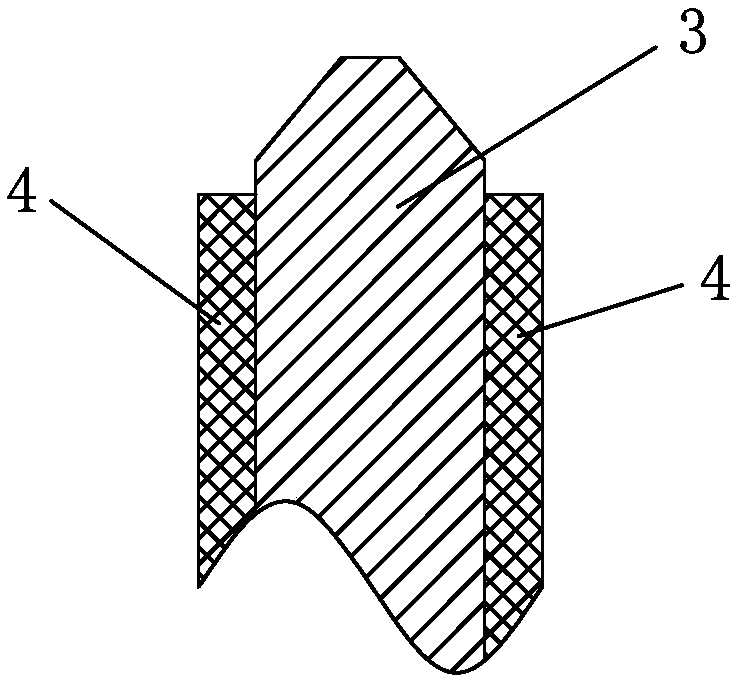

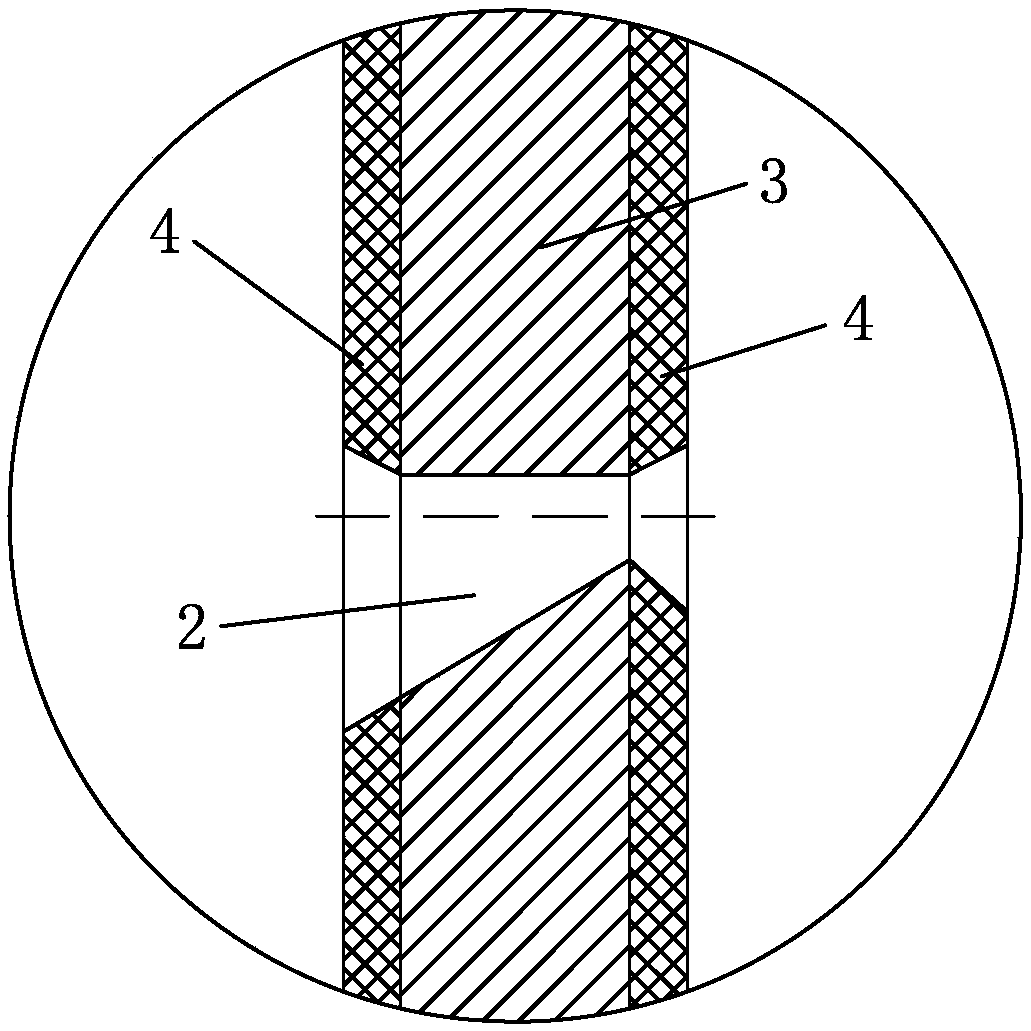

[0016] Such as Figure 1~3 , a compartment grate plate of a continuous ball mill with large output and low energy consumption for the ceramic industry, comprising a grate plate 1 and a grate slit 2, the grate plate 1 is circular, the size of the grate plate 1 is the same as the internal diameter of the ball mill chamber, and the grate plate 1 is made of metal Composed of a layer and a wear-resistant layer, four circles of grate slits 2 are arranged on the grate plate 1 with the center of the grate plate 1 as the center, each circle has several grate slits 2, and the distance between two adjacent grate slits 2 in each circle Similarly, one side of the grate slit 2 has a large opening and the other side has a small opening. The opening is at a certain angle. The angle direction is set according to the rotation direction of the grate plate 1, which can effectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com