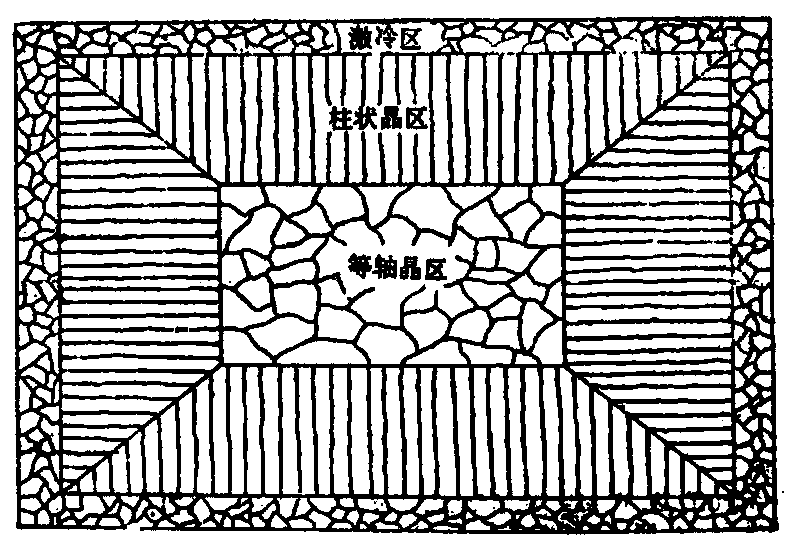

Production Method for Improving Microstructure Uniformity of Continuous Casting Billet

A production method and uniform structure technology, applied in the production field of improving the uniform structure of continuous casting billet, can solve the problems of low production efficiency, large thermal inertia, long heating time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

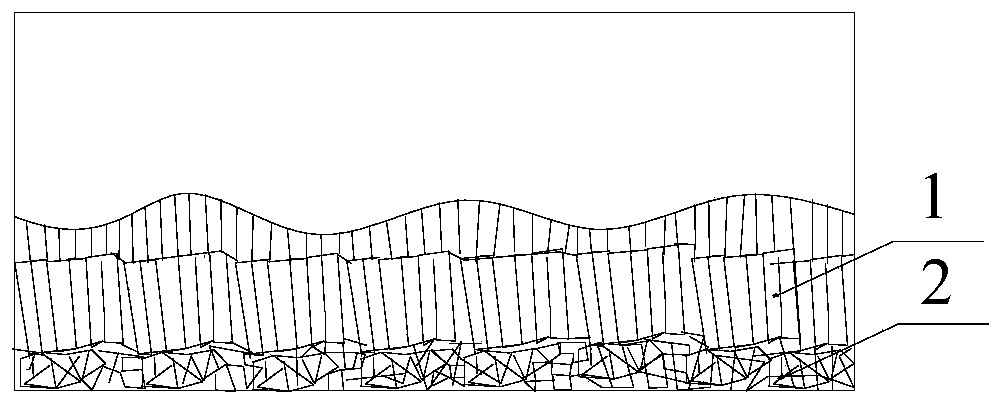

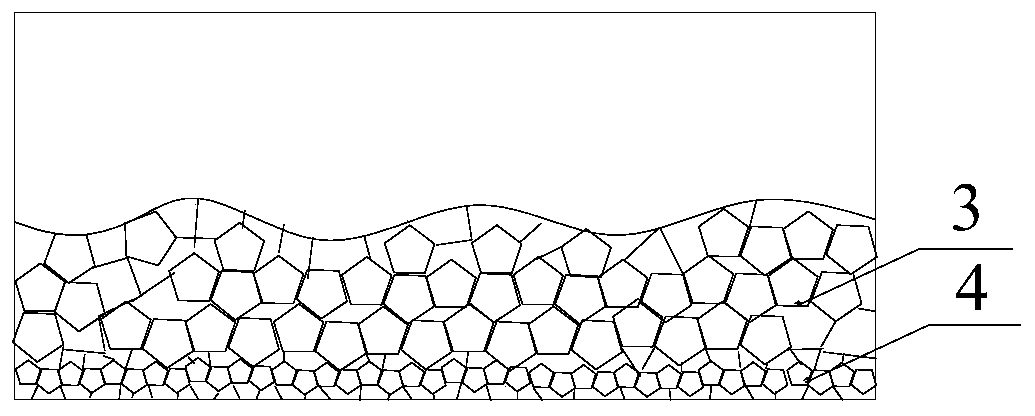

Method used

Image

Examples

Embodiment Construction

[0069] By controlling the chemical composition of low-alloy high-strength bridge cable steel and controlling the heat treatment process parameters, a finer and more uniform structure can be obtained. The present invention will be further described in detail below in conjunction with the accompanying drawings, specific embodiments and comparative examples, so as to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

[0070] Table 1 is that the composition of each embodiment of the present invention and comparative example is all the same, and concrete composition and weight percent are as table 1, and surplus is iron;

[0071] Table 2 is each embodiment of the present invention and comparative example electromagnetic induction coil heating process parameter list;

[0072] Table 3 is a test list of various embodiments of the present invention and comparative examples.

[0073] Table 1 (wt,%)

[0074] C Si mn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com