Special-shaped bearing support production method and bearing support produced through same

A manufacturing method and support frame technology, which is applied to earth movers/excavators, construction, etc., can solve the problems of poor quality of finished parts, increased production costs, and low production efficiency, so as to reduce errors, facilitate assembly, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

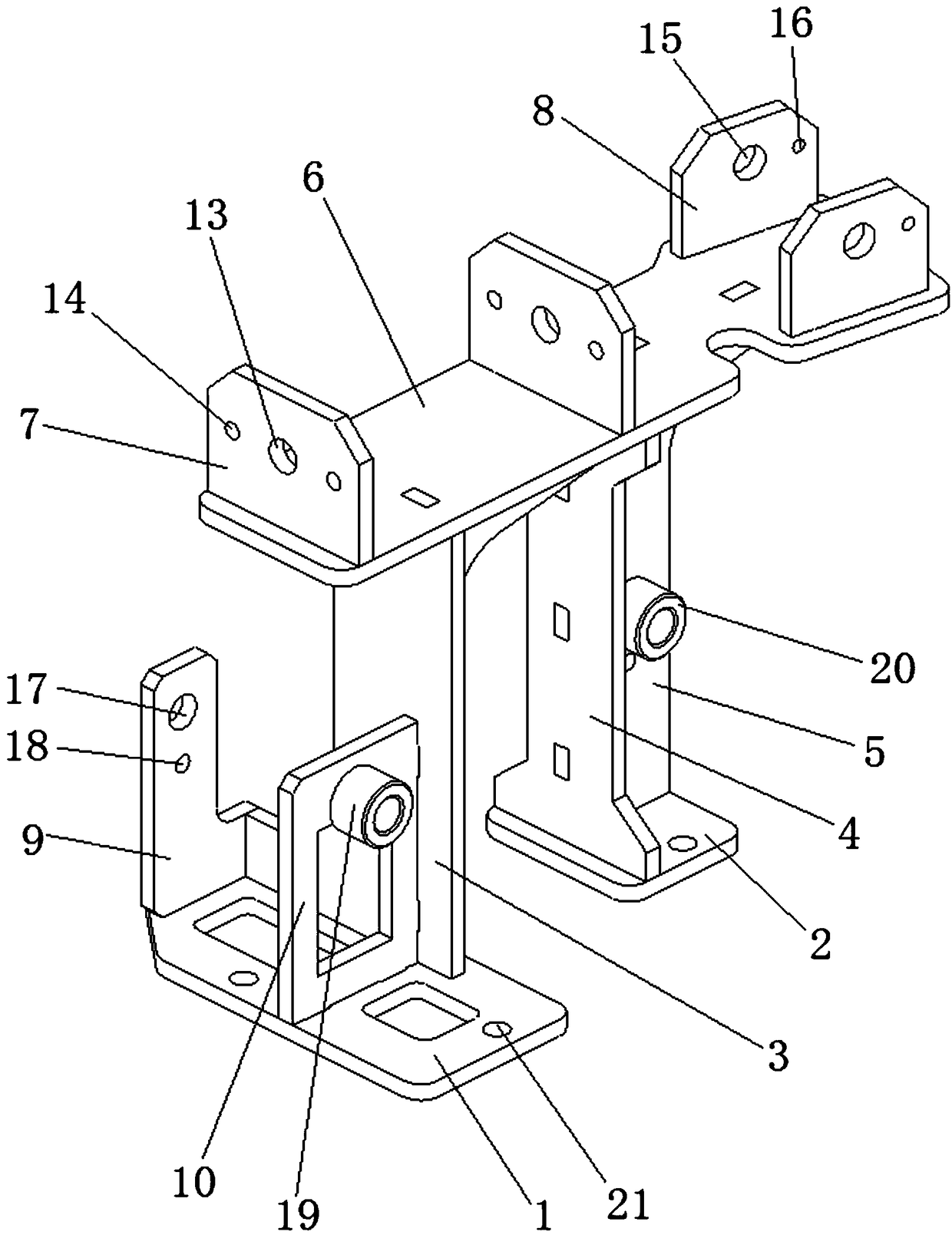

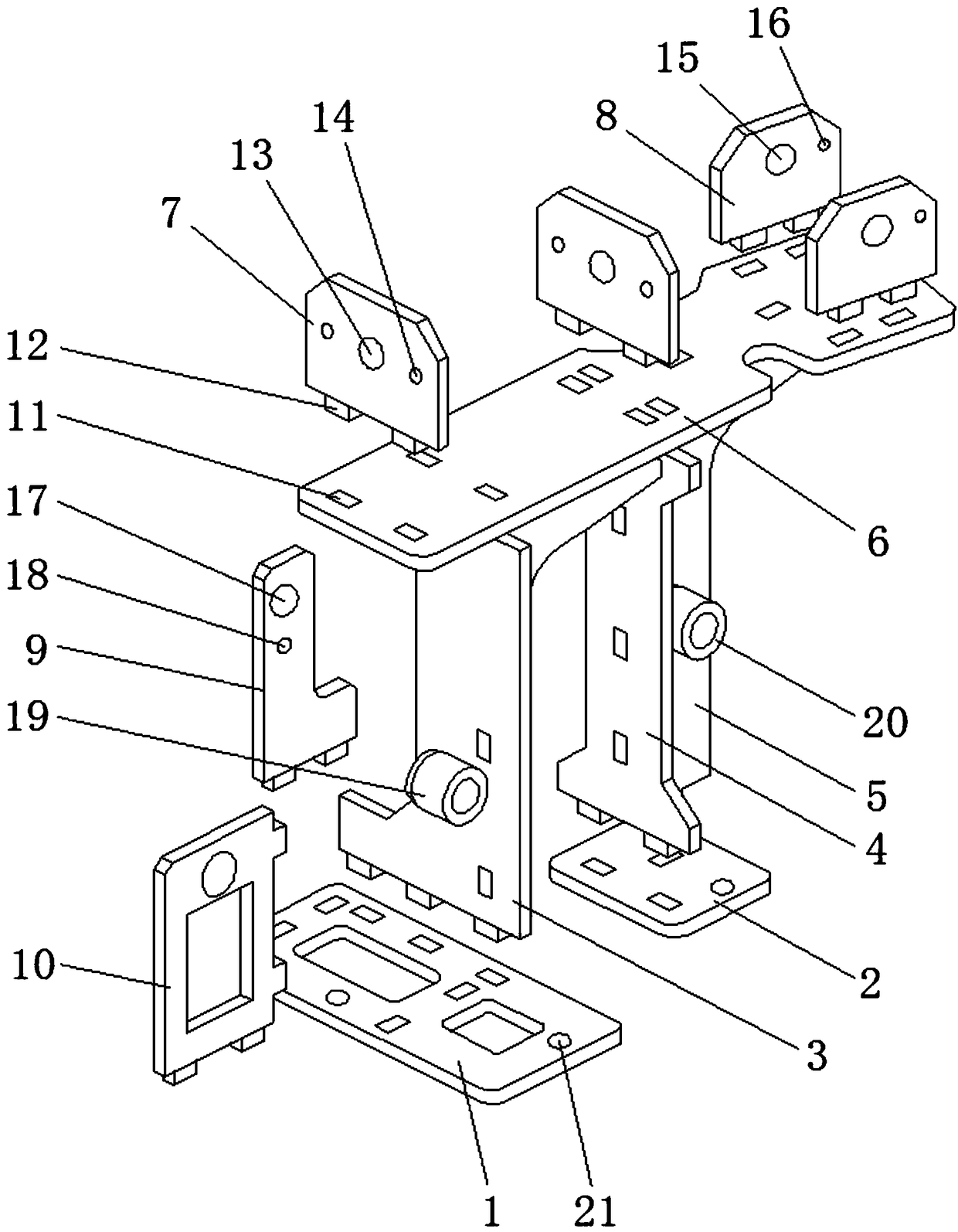

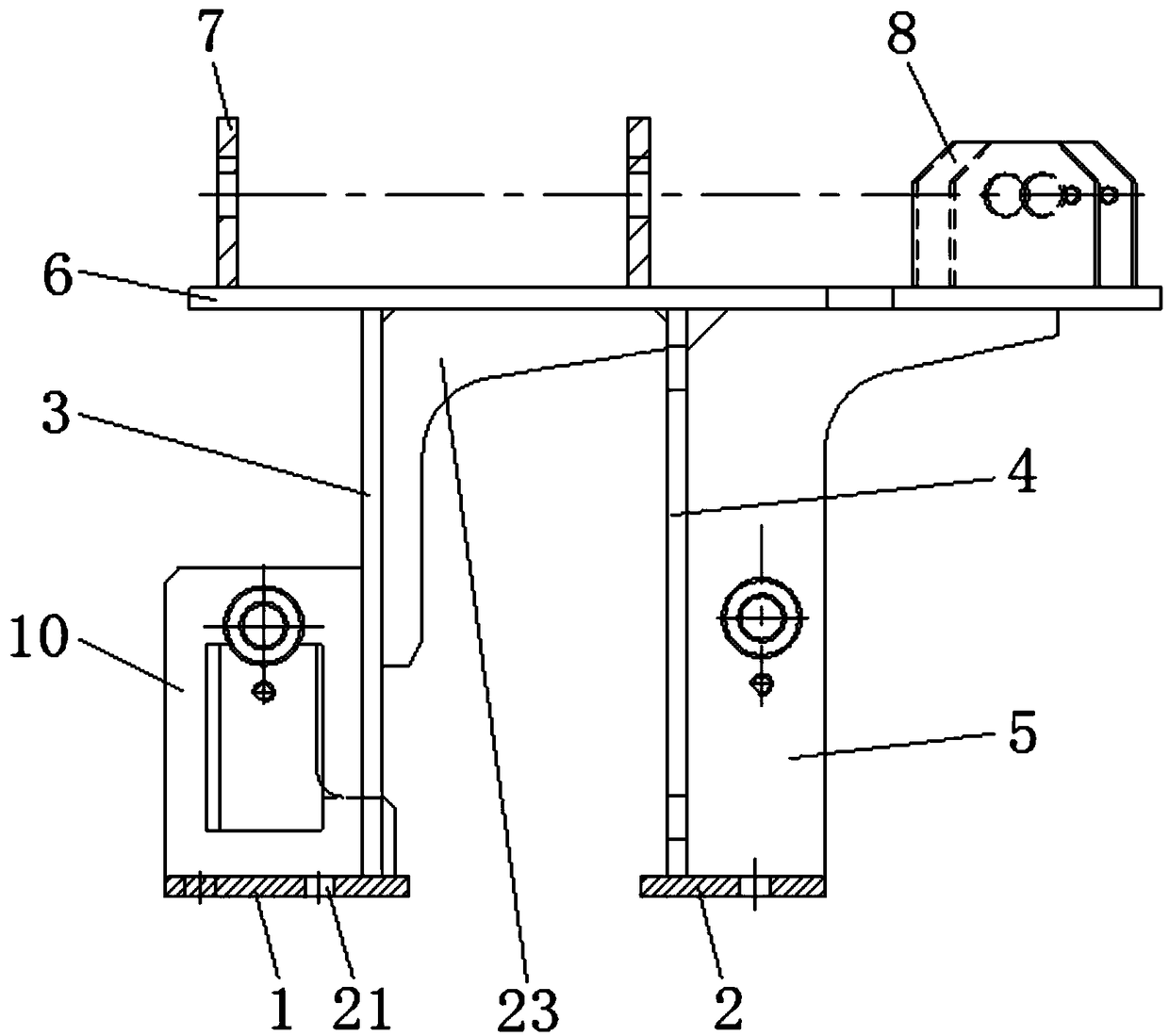

[0035] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

[0036] refer to Figure 1-7 , a method for manufacturing a special-shaped support frame, the method is to decompose the support frame into a plurality of parts with a flat structure and process them separately, assemble the processed parts in the form of building block clamping, and adjust the distance between two adjacent parts The clamping section is reinforced.

[0037] The multiple parts include the first bottom plate 1, the second bottom plate 2, the first vertical plate 3, the second vertical plate 4, the third vertical plate 5, the top plate 6, the first mounting plate 7, the second mounting plate 8, the third mounting plate Plate 9, the fourth mounting plate 10, the manufacturing method specifically includes the following steps,

[0038] S1. Part blanking: According to the design requirements of the part drawings, the first bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com