Multisensory system for industrial robot

A technology of industrial robots and perception systems, applied in the field of industrial robot control systems, can solve problems such as insufficiently intuitive teaching actions, low programming efficiency, and limited productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

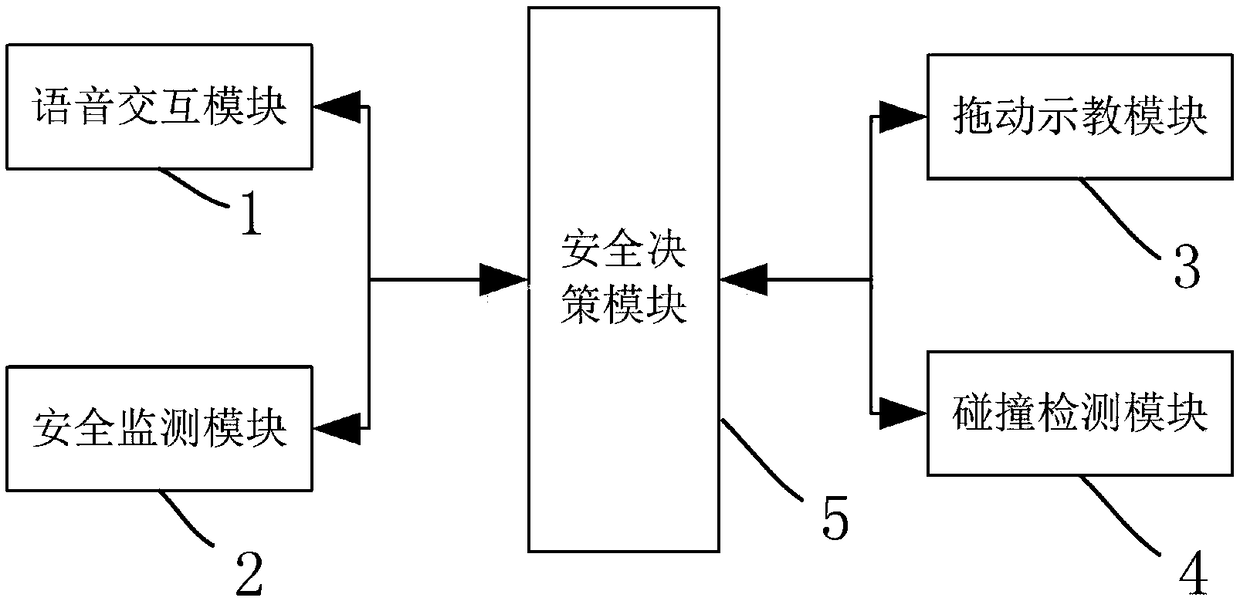

[0036] refer to figure 1 , the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

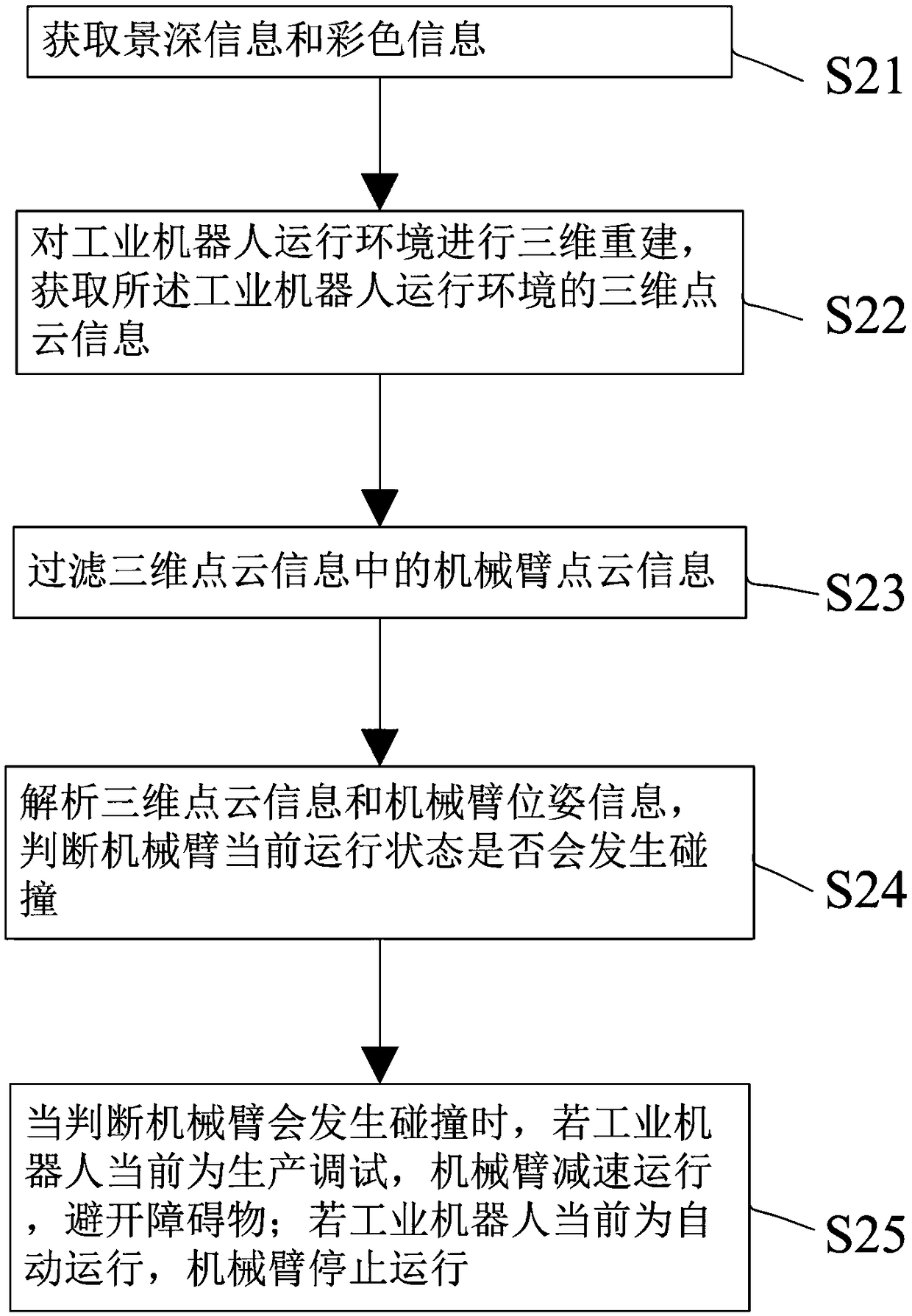

[0037] A multi-sensing system for an industrial robot provided by the present invention includes a voice interaction module 1, a safety monitoring module 2, a drag teaching module 3, a collision detection module 4 and a safety decision module 5;

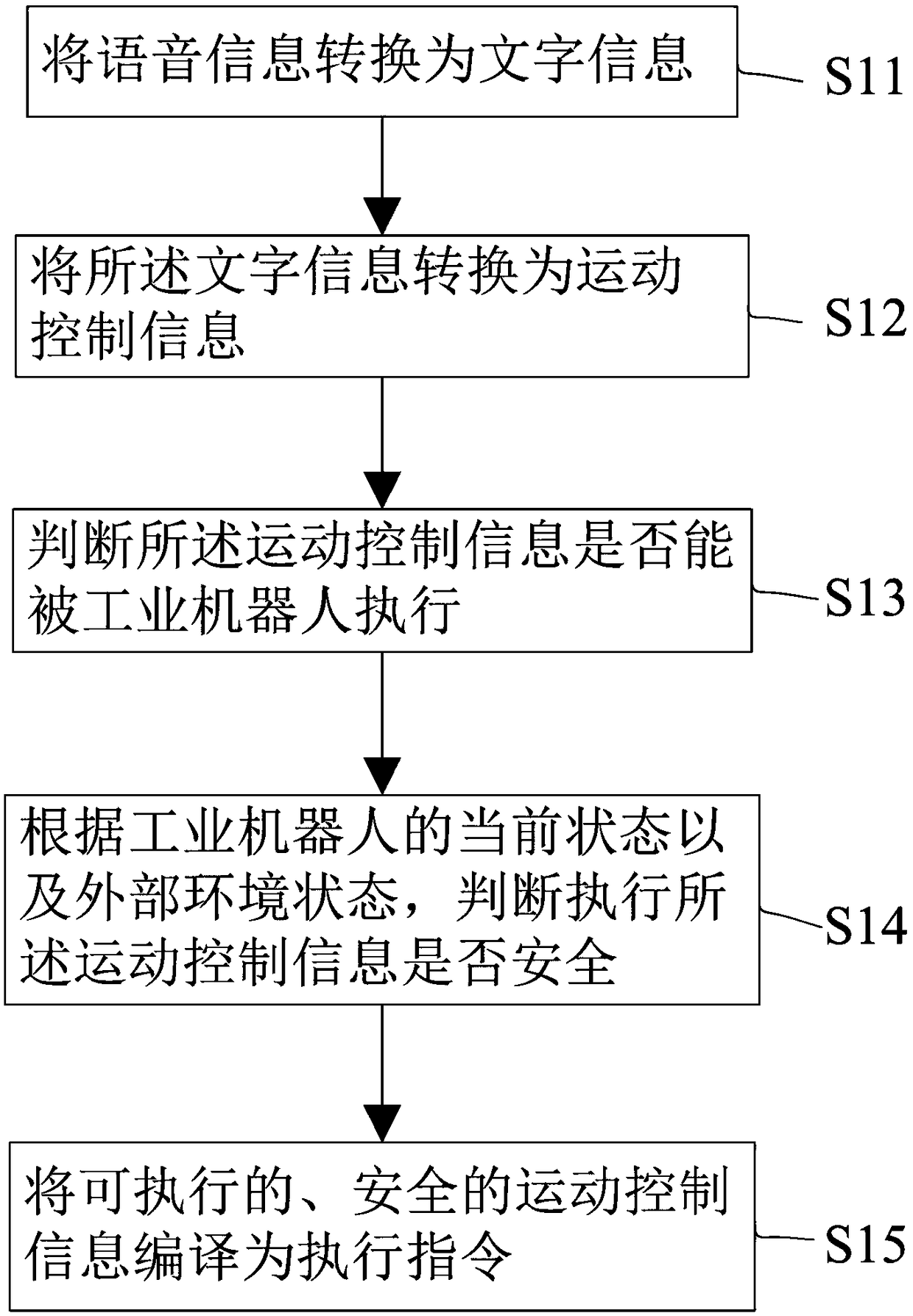

[0038] The voice interaction module 1 is used to identify the received voice information and generate execution instructions;

[0039] The voice interaction module 1 is software developed based on a deep learning voice recognition algorithm. In this embodiment, the voice recognition tool based on the iFLYTEK AIUI human-computer interaction platform is applied to the industrial robot, and by extending the robot operation and control methods , so that the operator can use voice, a more natural interaction method, so that the robot can correctly understand the human intenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com