A modified asphalt mixture with good weather resistance and its preparation method

A modified asphalt and mixture technology, applied in the field of modified asphalt, can solve the problems of asphalt hardening and cracking, reduce the road performance and service life of asphalt pavement, and achieve the extension of road life, excellent anti-aging performance, and enhanced heat resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

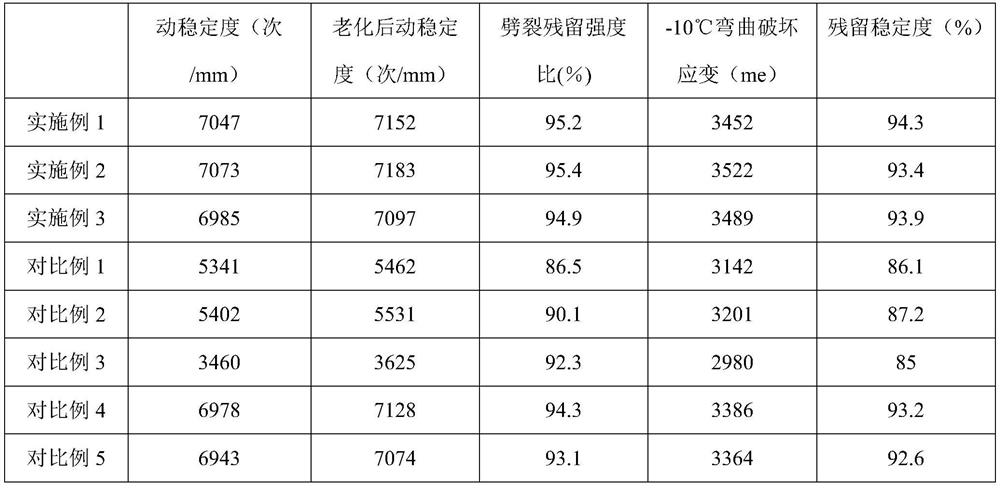

Examples

Embodiment 1

[0035] A kind of SBS modified bitumen is obtained through the following steps:

[0036]Step 1. Weigh the raw materials according to the following parts by weight: 100 parts of base asphalt, 5 parts of SBS modifier, 3.5 parts of xylan-chitosan complex, poly(dicyclopentadiene-co-p-cresol) 5 parts, 3 parts of polyacrylamide methyl benzylidene camphor, 0.7 parts of decyl acrylonitrile dimethyl siloxane and 0.8 parts of 4-benzoyloxy-2,2,6,6-tetramethylpiperidine share;

[0037] Step 2, heating the base asphalt to 135-145°C, adding SBS modifier, xylan-chitosan complex, poly(dicyclopentadiene-co-p-cresol), polypropylene to the base asphalt Amidomethylbenzylidene camphor, decylacrylonitrile dimethylsiloxane and 4-benzoyloxy-2,2,6,6-tetramethylpiperidine, heat up to 170~190℃, keep the reaction temperature, stirring for 20-30min to make the raw materials mix evenly, grind in the colloid mill for 0.5-1h, after stopping the colloid mill, keep the reaction temperature at 170-190°C, and c...

Embodiment 2

[0039] A kind of SBS modified bitumen is obtained through the following steps:

[0040] Step 1. Weigh the raw materials according to the following parts by weight: 100 parts of base asphalt, 5 parts of SBS modifier, 3.5 parts of xylan-chitosan complex, poly(dicyclopentadiene-co-p-cresol) 5 parts, 3 parts of polyacrylamide methyl benzylidene camphor, 0.7 parts of decyl acrylonitrile dimethyl siloxane and 0.8 parts of 4-benzoyloxy-2,2,6,6-tetramethylpiperidine share;

[0041] Step 2, heating the base asphalt to 135-145°C, adding SBS modifier, xylan-chitosan complex, poly(dicyclopentadiene-co-p-cresol), polypropylene to the base asphalt Amidomethylbenzylidene camphor, decylacrylonitrile dimethylsiloxane and 4-benzoyloxy-2,2,6,6-tetramethylpiperidine, heat up to 170~190℃, keep the reaction temperature, stirring for 20-30min to make the raw materials mix evenly, grind in the colloid mill for 0.5-1h, after stopping the colloid mill, keep the reaction temperature at 170-190°C, and ...

Embodiment 3

[0043] A kind of SBS modified bitumen is obtained through the following steps:

[0044] Step 1. Weigh the raw materials according to the following parts by weight: 95 parts of base asphalt, 4 parts of SBS modifier, 2 parts of xylan-chitosan complex, poly(dicyclopentadiene-co-p-cresol) 3 parts, 2.5 parts of 3,4'-methylbenzylidene camphor, 0.5 parts of decylacrylonitrile dimethylsiloxane, and 4-benzoyloxy-2,2,6,6-tetramethylpiperidine 0.5 servings;

[0045] Step 2, heating the base asphalt to 135-145 ℃, adding SBS modifier, xylan-chitosan complex, poly(dicyclopentadiene-co-p-cresol), 3, 4'-methylbenzylidene camphor, decylacrylonitrile dimethylsiloxane and 4-benzoyloxy-2,2,6,6-tetramethylpiperidine, heat up to 170-190°C, keep At the reaction temperature, stir for 20-30 minutes to make the raw materials evenly mixed, and grind them in a colloid mill for 0.5-1 h. After stopping the colloid mill, keep the reaction temperature at 170-190°C and continue stirring for 2-3 hours to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com