High-density culture method for yeast

A high-density culture, yeast technology, applied in fungi and other directions, can solve the problems of complex control equipment, not very suitable, and achieve the effects of low investment, improved utilization, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

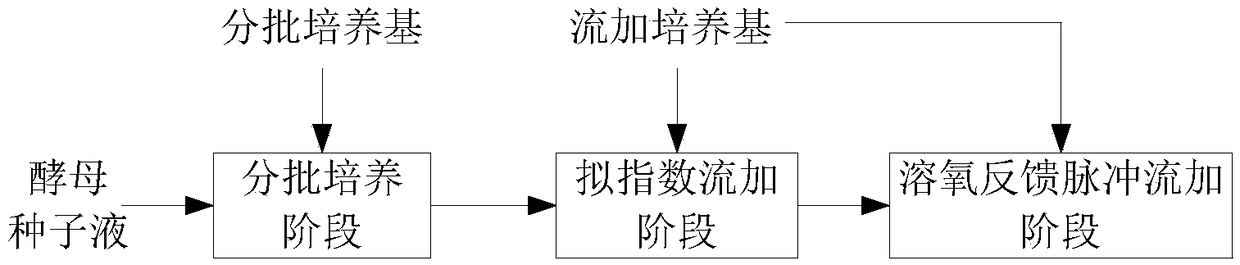

Method used

Image

Examples

Embodiment 1

[0034] 1) Batch culture: put 1L medium in a 5L mechanically stirred ventilated fermenter, insert 100mL yeast seed culture liquid to start fermentation, and the yeast seed liquid cell concentration is 1×10 8 unit / ml, dilute H was used in the fermentation process 2 SO 4 Or dilute NaOH solution to maintain the pH between 4.5-5.0, and the jacket passes through cooling water to control the fermentation temperature at 26-28°C.

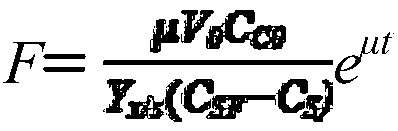

[0035] 2) Exponential fed-batch feeding: After about 18 hours of batch culture, the fermentable sugar is consumed, and when the dissolved oxygen rises to 60%, the feeding pump is turned on, and the feeding method is according to the feeding formula Execute (wherein the yeast specific growth rate μ is set to 0.02h -1 ).

[0036] 3) Dissolved oxygen feedback pulse feeding: Exponential feeding for about 45 hours, 2.0g / L ethanol was detected in the fermentation broth, and the feeding mode was changed to dissolved oxygen feedback pulse feeding, that is, dissol...

Embodiment 2

[0038] 1) Batch culture: put 1L medium in a 5L mechanically stirred ventilated fermenter, insert 100mL seed culture solution to start fermentation, and the concentration of yeast seed solution is 1×10 8 unit / ml, dilute H was used in the fermentation process 2 SO 4 Or dilute NaOH solution to maintain the pH between 5.0-5.5, and the jacket passes cooling water to control the fermentation temperature at 28-30°C.

[0039] 2) Exponential fed-batch feeding: After about 18 hours of batch culture, the fermentable sugar is consumed, and when the dissolved oxygen rises to 60%, the feeding pump is turned on, and the feeding method is according to the feeding formula Execute (the specific growth rate μ of yeast is set to 0.03h -1 ).

[0040] 3) Dissolved oxygen feedback pulse feeding: Exponential feeding for about 45 hours, 2.0g / L ethanol was detected in the fermentation broth, and the feeding mode was changed to dissolved oxygen feedback pulse feeding, that is, dissolved oxygen was a...

Embodiment 3

[0042] 1) Batch culture: put 1L medium in a 5L mechanically stirred ventilated fermenter, insert 100mL seed culture solution to start fermentation, and the concentration of yeast seed solution is 1×10 8 unit / ml, dilute H was used in the fermentation process 2 SO 4 Or dilute NaOH solution to maintain the pH between 5.5-6.5, and the jacket passes cooling water to control the fermentation temperature to 30-34°C.

[0043] 2) Exponential fed-batch feeding: After about 18 hours of batch culture, the fermentable sugar is consumed, and when the dissolved oxygen rises to 60%, the feeding pump is turned on, and the feeding method is according to the feeding formula Execution (wherein the yeast specific growth rate μ is set to 0.04h -1 ).

[0044] 3) Dissolved oxygen feedback pulse feeding: Exponential feeding for about 45 hours, 2.0g / L ethanol was detected in the fermentation broth, and the feeding mode was changed to dissolved oxygen feedback pulse feeding, that is, dissolved oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com