Slot insulation method of flat wire motor stator

A motor stator and slot insulation technology, applied in the direction of laying solid insulation, winding insulation shape/style/structure, electromechanical devices, etc., can solve problems such as labor-intensive, limited production efficiency, insulation layer damage, etc., to improve processing efficiency , Improve the coordination stability, increase the effect of surface heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

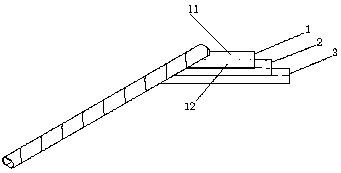

[0046] The slot insulation method for the flat wire motor stator includes the flat wire motor stator, the flat wire motor stator is provided with a stator slot, and the feature is that an insulating tube is arranged in the stator slot, and the insulating tube is integrally formed The insulating tube; the insulating tube is symmetrically inserted into the inside of the stator slot.

[0047] Further, the method for symmetrically inserting the insulating tube into the stator slot includes the following steps:

[0048] S1. Select the formed insulating sleeve that matches the size of the stator slot of the flat wire motor, and cut and pre-process the length of the insulating sleeve according to the size of the stator;

[0049] S2. Put the flat wire motor stator to be intubated into the positioning sleeve and fix it;

[0050] S3. Put the pre-processed insulating sleeve into the feeding mechanism, and send it to the rear positioning mechanism through the transmission mechanism;

[...

Embodiment 2

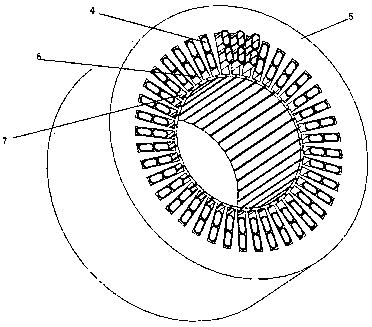

[0061] This embodiment provides a flat wire motor stator on an electric vehicle drive motor, such as figure 2 with image 3 , including the stator body 5 and the stator teeth 6 arranged on the inner ring of the stator body, the stator slots 7 for accommodating the stator windings are formed between the adjacent stator teeth, and two stator slots as in the embodiment are inserted in the stator slots The electric vehicle drive motor stator insulating sleeve 4 described in 1.

[0062] In this embodiment, the stator body is formed by lamination of multiple layers of annular silicon steel sheets, and after the lamination is formed, the stator slot is punched out by a punch.

Embodiment 3

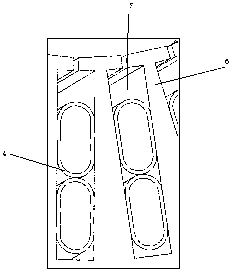

[0064] This embodiment provides a flat wire motor stator of a driving motor for an electric vehicle, such as Figure 4 , including the stator body 5 and the stator teeth 6 arranged on the inner ring of the stator body, the stator slots 7 for accommodating the stator windings are formed between the adjacent stator teeth, and two stator slots as in the embodiment are inserted in the stator slots The brushless DC motor stator insulating sleeve 4 described in 1; a metal strip 8 is inserted into the insulating sleeve 4 .

[0065] Further, the stator body is formed by laminating multiple layers of annular silicon steel sheets.

[0066] Further, both ends of the stator body are provided with short-circuit rings 9 for connecting metal strips in adjacent stator slots.

[0067] In this embodiment, the metal strips are commercially available enamelled copper strips or bare copper strips.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com