Fragrance-increasing type instant black tea and preparation method thereof

A technology of instant black tea and aroma type, which is applied in the direction of tea, tea extraction, tea treatment before extraction, etc. It can solve the problems of high nutrient retention rate, light taste, low aroma, etc., and achieve the effect of improving instant characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

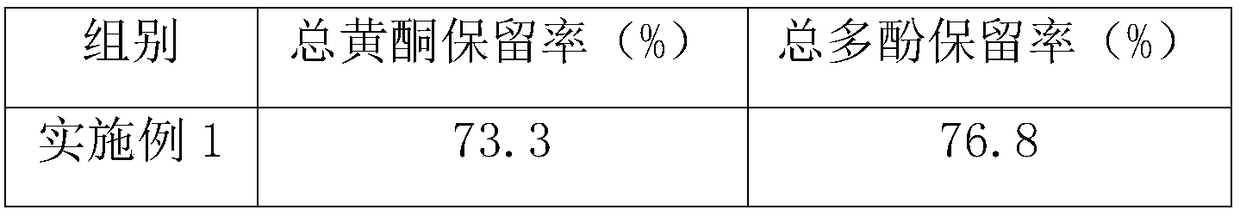

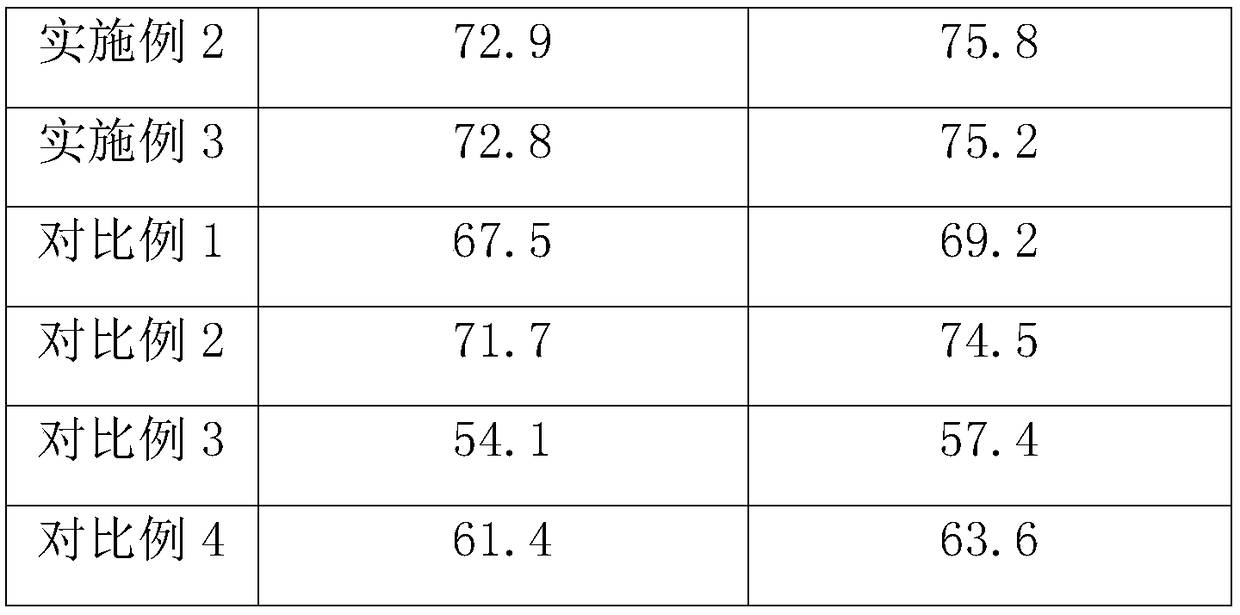

Examples

Embodiment 1

[0022] The preparation method of the instant black tea beverage of the present embodiment, carries out following steps successively:

[0023] 1), the main material is moderately broken;

[0024] 2) Add the main ingredients into pure water, heat and extract for 16-17 minutes to obtain the extraction juice, wherein the extraction temperature is controlled at 70-85°C, and the weight ratio of water to main ingredients is 28:1;

[0025] 3) The extract obtained in step 2) is selected from a ceramic membrane tube with a pore size of 0.5 μm, and the ceramic membrane is filtered under the conditions of 0.2 Mpa and 20-25° C. to obtain the filtrate;

[0026] 4), dissolve the composite wall material in pure water, add it into the filtrate obtained in step 3) after homogenization, and prepare microcapsules by ultrasonic, wherein the pure water is 10% of the weight of the extract, and the wall material is selected from carboxymethyl-β - Cyclodextrin, maltodextrin and casein, the ultrasonic...

Embodiment 2

[0033] The preparation method of the instant black tea beverage of the present embodiment, carries out following steps successively:

[0034] 1), the main material is moderately broken;

[0035] 2) Add the main ingredients into pure water, heat and extract for 16-17 minutes to obtain the extraction juice, wherein the extraction temperature is controlled at 70-85°C, and the weight ratio of water to main ingredients is 25:1;

[0036] 3) The extract obtained in step 2) is selected from a ceramic membrane tube with a pore size of 0.5 μm, and the ceramic membrane is filtered under the conditions of 0.2 Mpa and 20-25° C. to obtain the filtrate;

[0037] 4), dissolve the composite wall material in pure water, add it into the filtrate obtained in step 3) after homogenization, and prepare microcapsules by ultrasonic, wherein the pure water is 10% of the weight of the extract, and the wall material is selected from carboxymethyl-β - Cyclodextrin, maltodextrin and casein, the ultrasonic...

Embodiment 3

[0044] The preparation method of the instant black tea beverage of the present embodiment, carries out following steps successively:

[0045]1), the main material is moderately broken;

[0046] 2) Add the main ingredients into pure water, heat and extract for 16-17 minutes to obtain the extraction juice, wherein the extraction temperature is controlled at 70-85°C, and the weight ratio of water to main ingredients is 30:1;

[0047] 3) The extract obtained in step 2) is selected from a ceramic membrane tube with a pore size of 0.5 μm, and the ceramic membrane is filtered under the conditions of 0.2 Mpa and 20-25° C. to obtain the filtrate;

[0048] 4), dissolve the composite wall material in pure water, add it into the filtrate obtained in step 3) after homogenization, and prepare microcapsules by ultrasonic, wherein the pure water is 10% of the weight of the extract, and the wall material is selected from carboxymethyl-β - Cyclodextrin, maltodextrin and casein, the ultrasonic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com